18

19

www.uscutter.com

www.uscutter.com

425.481.3555

425.481.3555

2

3

4

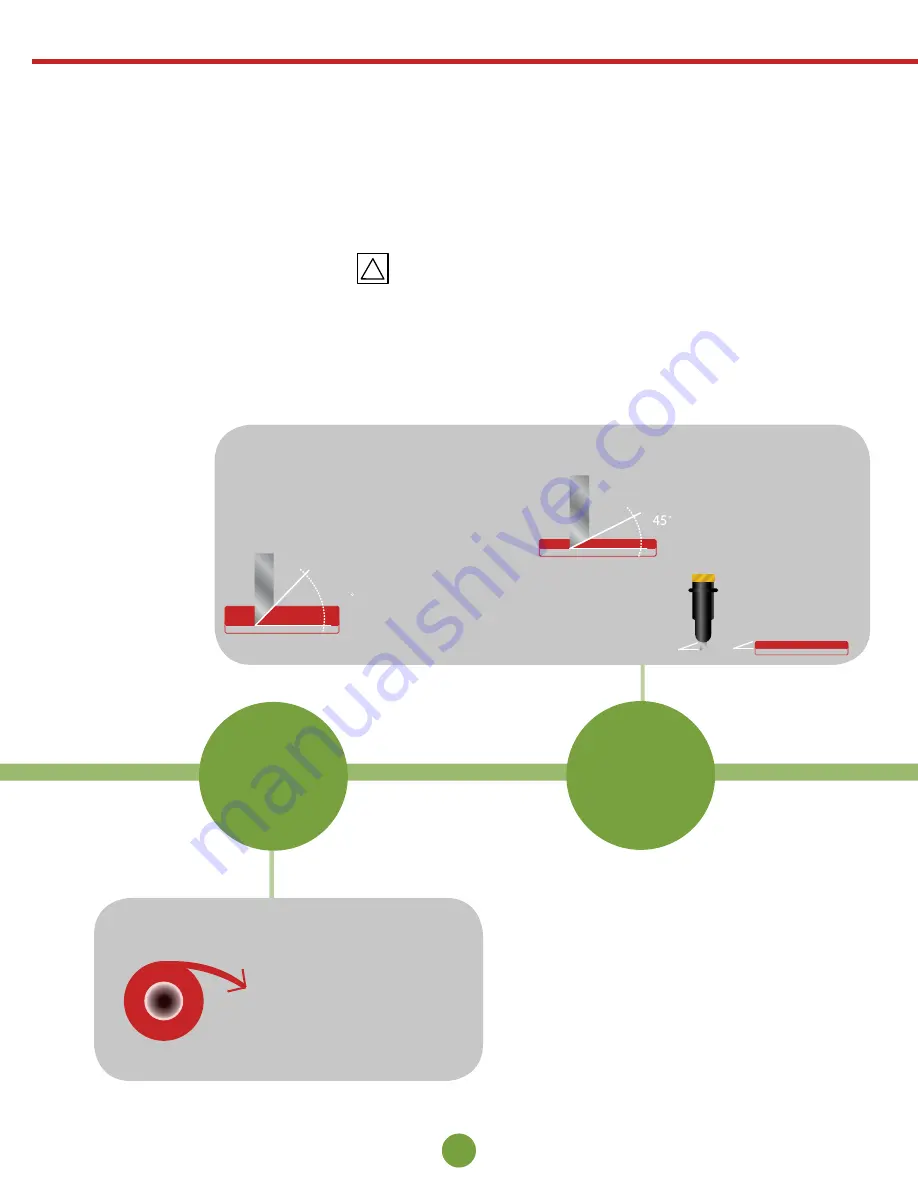

LOAD MATERIAL

CHOOSE BLADE

For thin and regular sized media,

use a 45

o

blade.

Load the blade so

that the length of the

blade shown is not

longer than

the media is

thick.

For thicker materials, such as Siser

StripFlock, Siser Glitter, and Hexis

CutFlex 600 Reflective,

a 60

o

blade is needed.

Most vinyl products are

loaded from over the top.

CUT SPEED

This setting determines how fast the design is cut out

and is usually measured in centimeters per second.

small intricate

designs

DECREASE CUT

SPEED

large simpler de-

signs

INCREASE

CUT SPEED

MEDIA

CARRIER

B

L

A

D

E

MEDIA

CARRIER

B

L

A

D

E

MEDIA

CARRIER

60

MEDIA

CARRIER

B

L

A

D

E

MEDIA

CARRIER

B

L

A

D

E

MEDIA

CARRIER

60

MEDIA

CARRIER

B

L

A

D

E

MEDIA

CARRIER

B

L

A

D

E

MEDIA

CARRIER

60

FORCE/PRESSURE

This setting determines how hard the blade comes down onto the material.

outer square

won’t weed

INCREASE

FORCE

blade digging too far

into carrier

DECREASE FORCE

weeds easily with a light-

ly scored carrier

PERFECT!

Test Cut

Making Your First Test Cut

A Basic Guide To Vinyl Cutting

Now that you’ve got your system fully

assembled let’s take a moment to test it and

also take moment to learn a bit about how

to “fine tune” the machine so that it will do

quality cuts on the different materials you’ll be

cutting. To do this we’ll do a standard test cut,

which when competed will a simple triangle

inside of a square. Load the material roll and

adjust the pinch rollers. Remember to make

sure the top roller is placed so that there is a

bottom roller (called the “grit roller”) beneath

it. Remember to line the material up so that it

is moving straight through the feed area, and

resist the temptation to run the material close

to the edge of the cutter feed area or you

increase the risk of a mis-feed that will wrinkle

your vinyl. (See the graphic on the top of pg.

21 for an example.)

Assuming you’re cutting standard signage

vinyl, you’ll want to use your 45° blade. If

you received vinyl along with your cutter

package, chances are very good it’s a standard

GreenStar or Oracal signage vinyl. Now, find

the TEST button on the cutter control pad and

press it. It should cut a pattern that looks like

this:

This Test Cut will help you to calibrate the

machine for this material. Examine this cut

and use a weeding tool or exacto knife to

weed the square out while keeping the

triangle on the paper. (“Weeding” is the word

for removing the cut vinyl in the design.)

Use this simple diagram to make adjustments.

There’s a certain amount of trial and error to it

at first, but you’ll quickly get a feel for it.

1

16

17