ZenCut Black User Manual

The Control Panel 3-4

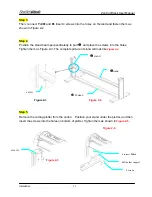

AAS Offset

Select: OK:ENTER

3.4 Menu Items

Below describes the functions of menu items

Menu or Key

Function

Setting

Default

--- Media sizing ---

Roll

To measure media width.

Maximum Tracking

150 meters

Edge

To measure media width and pull media back until front paper

sensor opens.

Maximum Tracking

150 meters

Single

To measure media width and length.

Maximum Tracking

10 meters

--- POWER ---

To indicate the power status.

[ Arrow Keys ]

1. To move the tool carriage position on X or Y axis.

2. To select functions or change values of settings.

[ ENTER ]

1. The displayed parameters will be saved automatically.

2. To set a new origin at the present tool carriage position.

In “offline” mode, moving the tool carriage to desired

position by [Arrow Keys], then press [ENTER] key to set a

new origin. While moving with the parameters of XY-axes

displayed, press [MISC] key will enable fine-tune

movement; press [MISC] key again to disable the function.

[ PAUSE/RESUME ]

To temporarily halt the cutting process.

To resume the process by press [Pause/Resume] key again.

[ ONLINE/OFFLINE ]

1. To switch between online mode and offline mode.

2. To stop the cutting job or abort changes of settings.

Once this key is pressed, the cutting job will be terminated

immediately and cannot be resumed.

[ OFFSET ]

To set or modify the distance between the blade tip and the

center axis.

0.000~1.000mm 0.275mm

[ FORCE ]

To set or modify the value of tool force.

5~600gram;

5 gram/per step

80 gram

[ SPEED ]

Speed

To set or modify horizontal tool speed.

3~153cm/sec;

3cm/sec per step

72cm/sec

Up Speed

To set or modify vertical tool speed.

3~153cm/sec;

3cm/sec per step

72cm/sec

Cutting Quality To set or modify cutting quality.

While cutting small letters, set as “Small letter”.

While cutting in high speed, set as “Draft”.

For normal operation, set as “Normal”.

Draft, Fair,

Normal, Fine,

Small Letter

Normal

[ CUT TEST ]

Summary of Contents for ZENCUT Black

Page 1: ...V1 June 09 User Manual...