16

USSC

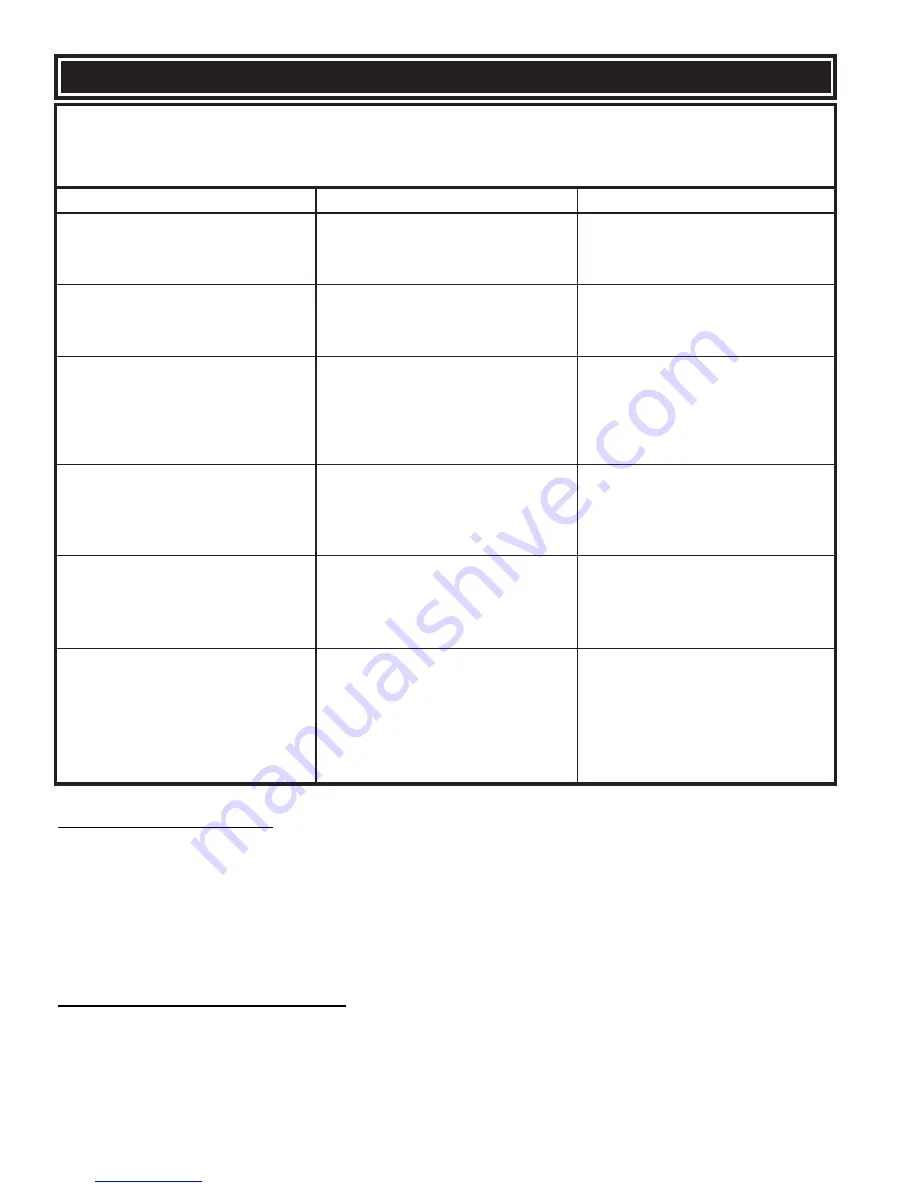

COMPONENT

OPERATION START

OPERATION END

CIRCUIT BOARD FUNCTIONS

START-UP SEQUENCE OF EVENTS

Once the control panel is turned to on, a timer begins that will start, stop and continue operation of the

American Harvest

as a preset temperature is achieved.

Exhaust Blower

Agitator

Auger

Room Fan

Automatic Shutdown

Normal Operation

Starts Immediately

Three minutes after starting the agita-

tor will begin to turn

Three minutes after starting the auger

will begin to turn

Begins when 110 degrees is reached.

If after 15 minutes, the

American

Harvest

has not reached the preset

operating temperature, the unit will

begin to automatically shut down.

If after 15 minutes the preset operat-

ing temperature of 110 degrees is

achieved, normal operation will con-

tinue.

Will continue until shutdown. Shutdown

will occur when the operating tempera-

ture is below 90 degrees.

Will continue intermittingly, has deter-

mined by the “HEAT SETTING”, until

shutdown

The auger will continue at the feed rate

specified by the “HEAT SETTING”.

NOTE:

Safety switches, HI limit and

vacuum sensor, must be activated to

continue proper operation.

Will continue to operate until the

AMERICAN HARVEST

cools down to

below 90 degrees. This may take sev-

eral minutes up to an hour.

Should the timer expire before the

preset operating temperature is

achieved, simply reset the stove by

pressing the “ON” buttton.

Operation will continue until either the

AMERICAN HARVEST

control is to

the “OFF” position, or the operating

temperature falls below 90 degrees. At

such time the

AMERICAN HARVEST

will default to the “Automatic Shut

Down”.

Adjusting the Air/Fuel Mixture

The two adjustments necessary for proper air/fuel mixture are the combustion air/blower setting and the auger run time setting. These two

adjustments are the basis for allowing this model the ability to burn many types of fuel in many different installations.

The auger run time adjustment is made by pressing the “A” button and adjusting the nine variables up or down as necessary. This allows the user

ultimate control of the amount of fuel delivered. Increasing the number displayed, feeds more fuel and lowering the number deceases the fuel.

When adjustments are needed for the Combustion air/blower, press “B” and adjust up or down as required. The adjustments made here are

saved automatically and applied to all nine heat ranges. Even though all nine heat ranges are affected, the lower ranges are adjusted the most.

These adjustments allow, “tweaking” your unit for maximum efficiency.

Note: On some models the “A” and “B” buttons are deactivated from the factory.

If activation of “A” and “B” is necessary

• Step 1 turn unit “ON”.

• Step 2 Press and hold the Blower “UP” arrow and the Heat range “DOWN” arrow at the same time for 5 seconds. In most cases, you will see

the numbers displayed in the heat range window and blower window blink. Then release the buttons and press “A” or “B” buttons to check

activation. When activated, pressing either button will display a light above that letter and display a single digit in the blower speed window. The

heat range window will be blank. If not activated, repeat the Step 1.

Downloaded from

www.Manualslib.com

manuals search engine