22

USSC

KEY

PART #

DESCRIPTION

QTY.

1

69437B

Ash Pan Guide Assy., Painted

1

2

25309B

Pedestal, Painted

1

3

25158B

Pedestal Trim, Painted

1

4

25317B

Pedestal Back, Painted

1

5

69364B

Ash Pan, Painted

1

6

69443

Hopper Assembly

1

7

891118

Safety Guard

1

8

25315B

Cabinet Top, Painted

1

9

25316B

Hopper Lid, Painted

1

10

89899

Brass Knob

2

11

25314B

Cabinet Back, Painted

1

12

80462

Power Supply Plug

1

N/S

80461

Power Supply Cord

1

13

80454

Exhaust Blower

1

14

86592

Exhaust Pipe

1

15

89586

Brass Nipple

1

16

80471

Pressure Switch

1

N/S

80312

Neoprene Tubing

3 ft.

N/S

80312

Neoprene Tubing

14 in.

17

69444B

Cabinet Side - Left, Painted

1

18

80470

Circuit Board

1

19

69383

Draft Adjustment Slide

1

20

891066

Knob

1

21

25312B

Cabinet Side - Right, Painted

1

22

80453

Distribution Blower

1

23

80456

Auger Motor

1

24

83511

Rubber Washer

1

25

891055

Coupling

1

26

80457

Agitator Motor

1

27

891083

Agitator Sprocket

1

28

891058

Chain

1

29

80455

Auger Safety Switch (F250 Thermodisc- 60T11)

1

30

80381

Low Limit Switch (F110 Thermodisc- 60T12)

1

31

80381

Distribution Blower Limit Switch (F110 Thermodisc- 60T12)

1

N/S

80477

Wiring Harness

1

N/S

80446

Wire (Green - 13”) - Ground

1

32

25170

Gold Trim Bracket

2

33

891073

Gold Trim

1

34

891075

Glass & Gasket

1

35

891076

Top Glass Retainer

1

36

891079

Bottom Glass Retainer

1

37

891078

Right Side Glass Retainer

1

38

891077

Left Side Glass Retainer

2

39

891074

Door

1

40

891089

Roller Latch Stop

1

41

891084

Door Handle

1

42

89574

Spring Handle

1

N/S

891089

Spring Pin, Door

1

43

891064

Ceramic Brick

1

44

891054

Auger

1

45

25173

Cleanout, Firebox

2

46

25325B

Cleanout Slides, Painted

2

47

69363

Burn Pot

1

48

891059

Agitator

1

49

69358

Shaft Collar

1

50

69359

Drive Shaft Weldment

1

51

83510

Drive Shaft Set Coupling

1

52

891092

Agitator Bushing

1

53

891057

Drive Shaft Sprocket

1

REPAIR PARTS LIST-6037

N/S = NOT SHOWN

FOR MODEL: 6037

Summary of Contents for American Harvest 6037

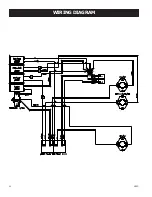

Page 20: ...20 USSC WIRING DIAGRAM ...

Page 21: ...USSC 21 REPAIR PARTS DIAGRAM 6037 45 ...

Page 23: ...USSC 23 Notes ...