USSC

9

Locate proper position for the type “PL” wall thimble (F).

Use a saber saw or keyhole saw to cut a 7 1/4-inch diameter hole through the wall (E) for a 3-inch pipe. For a 4-inch

pipe, cut an 8 1/4-inch hole. Install the wall thimble (F)in the hole. The size of hole opening will vary with brand of wall

thimble.

Position stove approximately 12” from the wall on the noncombustible floor pad. Push the type “PL” pipe (B) through the

wall thimble (D). Squeeze a bead of high temperature RTV silicone sealer (A) around the outside of the 3” diameter

exhaust pipe approximately ½” from the stove back panel. Firmly push on a section of type “PL” pipe (B) until the inner

pipe liner pushes up against the bead of RTV sealer. Don’t seal the entire 3” diameter pipe as you will not be able to

disassemble the pipe at a later date. The bead of silicone will act as a gasket right on the end of the 3” pipe (B).

Alternate Method:

An approved type “PL” connector back clamp may be used to allow easy disconnect for mainte-

nance. (The RTV sealant must be used in mobile home installation)

Push stove with pipe attached towards wall. Pipe (B) will go through the wall thimble (F). Be careful not to dislodge the

thimble. Position stove not closer than 9” to the wall

.

Install type “PL” termination cap (G) with rodent screen cap (optional) on outside end or pipe.

Note:

The end of the

exhaust pipe must extend a minimum of 12 inches from the outside of the building. Rodent screen cannot be less than

3/8” opening mesh.

If installing with combustion air from outside, cut a separate hole through the wall for the fresh air tube (C). This tube

must be 2” minimum diameter pipe. Connect outside air pipe inlet on stove. This tube must be terminated with a 90

degree elbow or hood.

Note: Always check dimensions on unit before cutting hole in wall

1)

2)

3)

4)

5)

6)

FREESTANDING STOVE INSTALLATION REQUIREMENTS

Horizontal Exhaust Termination:

Dimensional tolerance ±0.25”

3’ Minimum

Vertical Pipe

Summary of Contents for American Harvest 6037

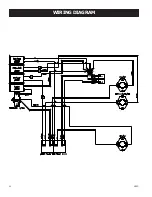

Page 20: ...20 USSC WIRING DIAGRAM ...

Page 21: ...USSC 21 REPAIR PARTS DIAGRAM 6037 45 ...

Page 23: ...USSC 23 Notes ...