11

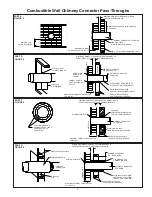

Crimped end of the pipe must be installed toward the heater. The

pipe should slide inside the flue collar. The pipe should be firmly

attached to the flue collar with 3 screws and sealed with furnace

cement.

Slope any horizontal pipe upward toward the chimney at least 1/4

" inch for each foot of horizontal run.

You must have at least 18" inches clearance between any horizon-

tal piping and the ceiling.

The pipe cannot extend into the chimney flue.(Fig. 8)

Seal each connector pipe joint with furnace cement. Also seal the

pipe at the chimney.

Use 3 sheet metal screws at each joint to make the piping rigid.

It is recommended that no more than two (2) 90 degree bends be

used in the stove pipe installation as more than two (2) may

decrease the amount of draw and possibly cause smoke spillage.

The chimney connector must not pass through an attic or roof

space, closet, or any concealed space, or floor, ceiling, wall or

combustible construction.

1.

2.

3.

4.

5.

6.

7.

8.

RULES FOR CONNECTOR PIPE INSTALLATION

Fig. 11