23

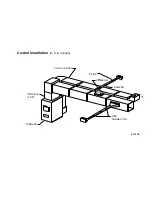

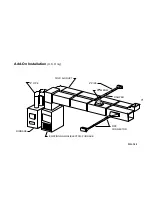

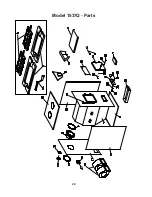

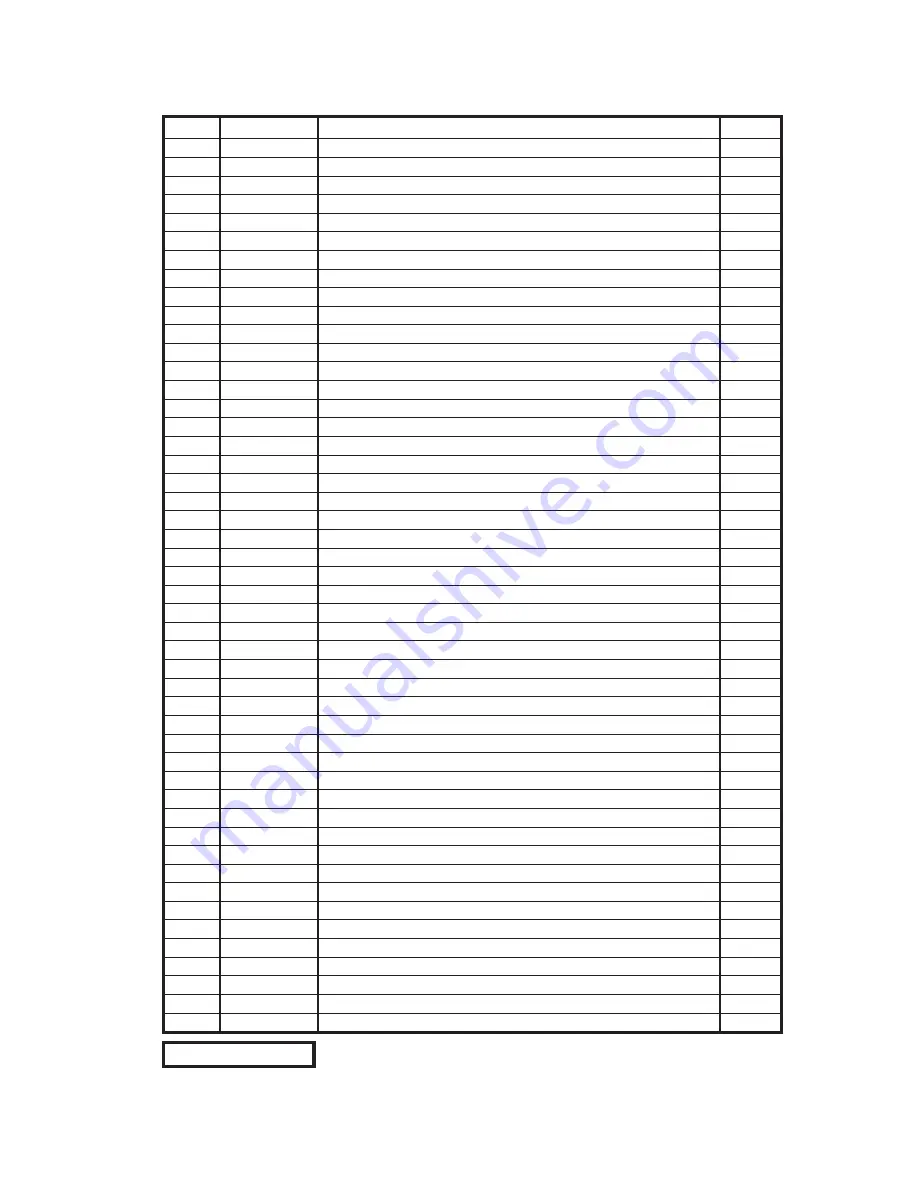

KEY

PART NO.

DESCRIPTION

QTY.

1

69092

Firebox Weldment

1

2

23398

Baffle

1

3

40246

Flue Collar Casting

1

4

88032

Flue Collar Gasket

1

N/S

83227

Bolt (1/4-20 x 1 MS, SL)

6

N/S

83250

Nut (Kep, 1/4-20)

6

5

69093

Cabinet Bottom Assembly

1

6

40258

Back Liner

1

7

40256

Shaker Frame

2

8

40257

Shaker Grate

2

9

89066

Firebrick

12

10

40269

Front Liner

1

11

68218

Ash Door Assembly

1

N/S

83476

Spacer

1

12

22824

Draft Control Knob

1

N/S

83345

3/8-16 x 1-3/4" Carr. Bolt

1

N/S

83450

Bolt (3/8-16 x 1-1/2)

2

N/S

83274

Locknut (3/8-16)

2

13

69091

Feed Door Assembly

1

14

C21399

Hinge Pin (5/16 x 1-1/2")

2

15

24512

Cabinet Side

2

16

69095

Cabinet Top Assembly

1

17

23459

Cabinet Back

1

18

22761

Flue Collar Ring

1

19

80230

Blower Motor

2

20

24179

Feed Door Handle

1

21

89574

Coil Door Handle (Brass Plated)

2

22

83444

Locknut (1/2-13)

2

23

83446

Flatwasher (9/16 ID)

1

24

23786

Door Latch

1

N/S

83409

Bolt (1/4 x 1/2 Hex)

2

N/S

80372

Nut (1/4 Hex)

2

N/S

23787

Smoke Door Clip

2

N/S

83445

Bolt (1/4-20 x 1-1/4")

2

N/S

83250

Nut (1/4-20 Kep)

2

25

80145

Limit Control

1

26

68234

Bracket (Blower Thermostat)

1

27

80131

Junction Box (4x4)

1

28

22140

Bracket (Relay Box)

1

29

24556

Ash Door Handle

1

30

83461

Handle Washer

1

31

83178

Nut (3/8-16 Jamb)

2

32

23445

Door Latch

1

33

23800

Smoke Curtain

1

34

40260

Shaker Handle

1

35

68228

Ash Pan Weldment

1

N/S

68231

Fan Control Cord Assembly (Flexible Conduit)

3

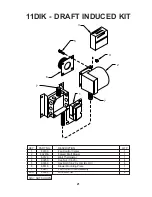

N/S

11DIK

Draft Induced Kit (See Page 21)

1

Model 1537Q - Parts List

N/S = NOT SHOWN