3

NOTE: Type of chimney: Class A All-Fuel UL 103HT

1. The furnace should be the only heating appliance using

a chimney flue. One furnace per flue.

2. A masonry chimney should have a tile or stainless steel

liner.

3. The masonry chimney should not have any missing

mortar or loose bricks.

4. There should be no mortar or parts of the chimney

blocking the chimney flue.

5. There should be a two inch clearance between any

chimney (masonry or metal) and combustibles (such

as the house).

6. The chimney should extend at least 2' above the

highest point of the house, or 2' above the point at

which the chimney is 10' from the roof.

7. The chimney should be relatively straight and vertical.

8. The portion of an all-fuel metal chimney that extends

above the roof should be well secured.

9. A masonry chimney should be built on footings and not

attached to the house.

10. A rain cap, complete with an animal or bird screen,

should be installed on top of the chimney.

CREOSOTE — FORMATION AND NEED

FOR REMOVAL

When wood is burned slowly, it produces tar and other organic

vapors, which combine with expelled moisture to form creosote.

The creosote vapors condense in the relatively cool chimney flue

of a slow-burning fire. As a result, creosote residue accumulates

on the flue lining. When ignited, this creosote makes an extremely

hot fire.

The chimney connector and chimney should be inspected at

least twice monthly during the heating season to determine if a

creosote build-up has occurred. If creosote has accumulated, it

should be removed to reduce the risk of a chimney fire.

SMOKE PIPE INSTALLATION

Clearances to combustible materials (i.e. paneling, ceiling tile,

sheet rock, plaster, draperies, casements or wood trim, etc.)

will vary with the type of flue connection used. Be sure to

maintain the specified clearances for your type of installation.

TYPE OF FLUE

REQUIRED

CONNECTION

CLEARANCE

24 Gauge or Heavier

18"

Single Wall Stainless Steel

or Black Pipe

Double Wall Stainless Steel

6"

Class A 103HT All-Fuel or Equivalent

2"

CEILING OR WALL

18"

9"

18"

COMBUSTIBLES

SMOKE PIPE

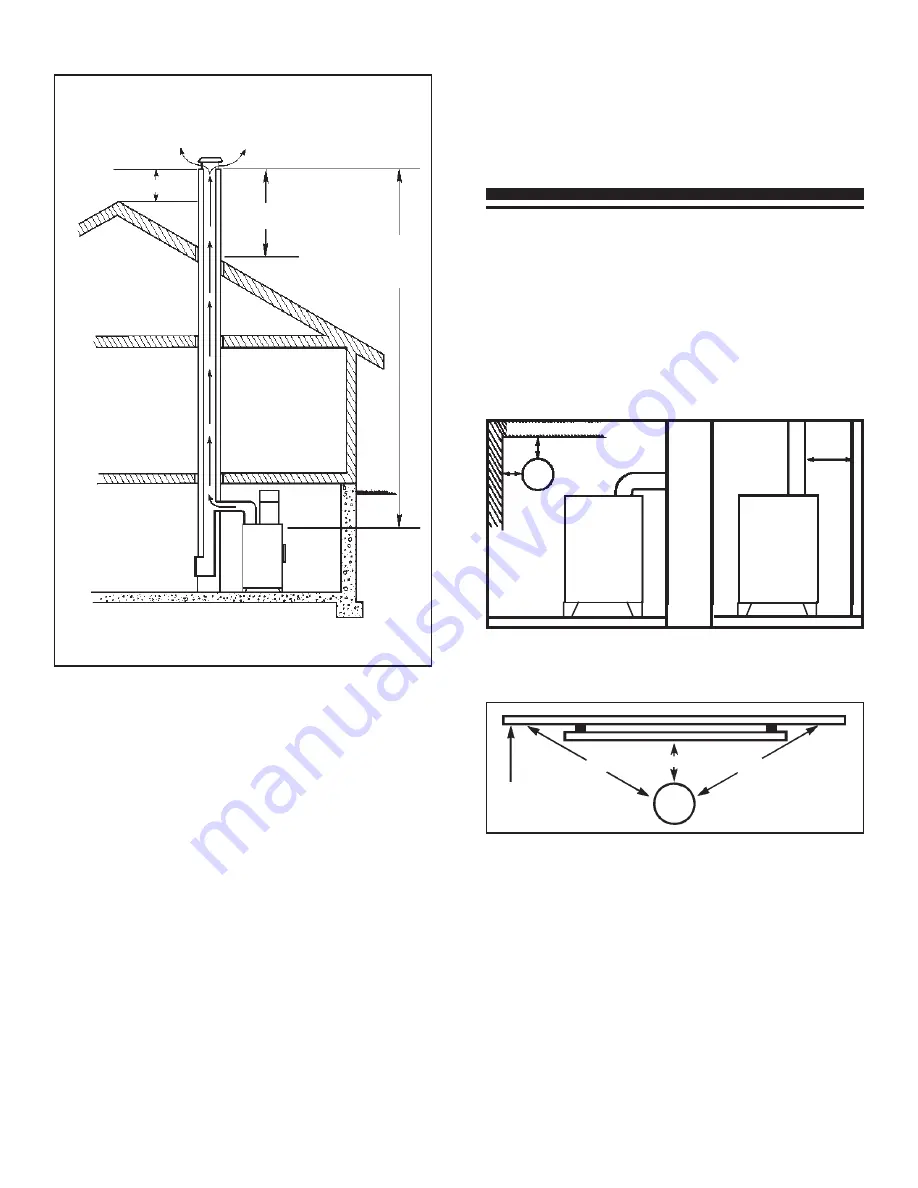

TOP OF CHIMNEY MUST

BE 2 FT. ABOVE HIGHEST

POINT OF ROOF WITHIN

10 FEET

2 FT.

MINIMUMS

3 FT.

MINIMUM

CAP SHOULD HELP

PREVENT DOWNDRAFT

WHILE STILL PROVIDING

ADEQUATE EXHAUST.

MINIMAL 3 FT.

FROM TOP OF

CHIMNEY TO POINT

AT WHICH IT PASSES

THROUGH THE ROOF.

RECOMMENDED

MINIMAL

20 FT. HEIGHT

CHIMNEY FLUE

SHOULD BE

CONSTANT DIAMETER

THROUGHOUT ITS

ENTIRE HEIGHT.

CHIMNEY FLUE

MUST BE AS

LARGE OR 20%

LARGER THAN

FURNACE FLUE

PIPE

APPROVED

CHIMNEY

CLEANOUT DOOR

SHOULD HAVE

AIRTIGHT FIT. DO

NOT LEAVE OPEN

WHEN FURNACE IS

IN OPERATION.

CHIMNEY THIMBLE SHOULD BE

CONSTRUCTED OF FIRE CLAY, AND

SHOULD FIT TIGHTLY TO FLUE PIPE.

According to NFPA standards, single wall stove pipes can be

within 9" of combustibles provided an approved fire retardant

material covered with 28 gauge sheet metal, spaced out 1" on

non-combustible spacers, is utilized. See illustration.

When using a Class A or double wall flue pipe connection,

follow the manufacturer's instructions.

When constructing a single wall smoke pipe, the following

guidelines must be observed.

1. The connector pipe should be 24 gauge or heavier

stainless steel or black pipe.

2. Secure all joints with three #8 screws.

3. If the connector pipe must pass through a wall, an ap-

proved insulated or ventilated thimble, at least three

times the diameter of the smoke pipe must be used. (i.e.

a 6" diameter smoke pipe needs an 18" thimble).

4. The connector pipe should never be used as a chimney.

IMPORTANT INFORMATION FOR

ALL CONNECTOR PIPES

The connector pipe must be constructed and installed so that it