1-3-15

2GM

Make test copies.

End of installation.

Using the one-touch key sheet.

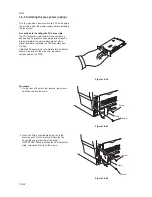

1. Remove the one-touch key sheet from bottom

side of the operation panel.

2. Enter the information for the registered

destinations onto the one-touch key sheet. (There

are 4 spare one-touch key sheets included with

this machine.)

3. Insert the sheet back between the one-touch

keys from the bottom side of the operation panel.

One-touch

key sheet

Figure 1-3-33

H- - - - - -

G- - - - - -

F- - - - - -

E- - - - - -

D- - - - - -

C- - - - - -

B- - - - - -

A- - - - - -

One-touch

key sheet

Figure 1-3-34

Summary of Contents for CD 1018

Page 1: ...Service Manual MFP Copy CD 1018 Date 17 03 2005 ...

Page 2: ...Service Manual MFP Copy DC 2018 Date 17 03 2005 ...

Page 70: ...2GM 1 5 2 2 Paper misfeed detection conditions Registration sensor Exit sensor Figure 1 5 2 ...

Page 124: ...2GM 1 6 31 Eraser lamp 9 Remove the eraser lamp Figure 1 6 35 Removing the eraser lamp ...