2DA/2DB

1-5-15

Problem

Causes/check procedures

Corrective measures

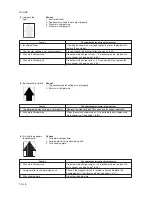

(24)

An original jams in

the original convey-

ing section is indi-

cated during copy-

ing (An original size

error jam).

Jam code 72

(25)

An original jams in

the original convey-

ing section is indi-

cated during copy-

ing (An original jam

in the original con-

veying section 2).

Jam code 73

(26)

An original jams in

the original convey-

ing section is indi-

cated during copy-

ing (An original jam

in the original con-

veying section 3).

Jam code 74

(27)

An original jams in

the original

switchback section

is indicated during

copying (An original

jam in the original

switchback section).

Jam code 75

(28)

Original jams fre-

quently.

Broken DP timing switch*

1

actuator.

Defective DP timing

switch*

1

.

Check if the original con-

veying motor*

1

malfunc-

tions.

Broken DP timing switch*

1

actuator.

Defective DP timing

switch*

1

.

Check if the original con-

veying motor*

1

malfunc-

tions.

Check if the switchback

feedshift solenoid*

1

mal-

functions.

Broken DP timing switch*

1

actuator.

Defective DP timing

switch*

1

.

Check if the original con-

veying motor*

1

malfunc-

tions.

Check if the switchback

feedshift solenoid malfunc-

tions*

1

.

Defective original

switchback switch*

1

.

Check if the original con-

veying motor*

1

malfunc-

tions.

Check if the switchback

feedshift solenoid*

1

mal-

functions.

An original outside the

specifications is used.

The DP forwarding pulley

or DP paper feed pulley is

dirty with paper powder.

The DP paper feed pulley

and DP separation pad do

not contact correctly.

Check visually and replace DP timing switch if its actuator is bro-

ken.

Run maintenance item U244 and turn DP timing switch on and

off manually. Replace DP timing switch if indication of the corre-

sponding switch is not light.

Run maintenance item U243 and select the original conveying

motor to be turned on and off. Check the status and remedy if

necessary.

Check visually and replace DP timing switch if its actuator is bro-

ken.

Run maintenance item U244 and turn DP timing switch on and

off manually. Replace DP timing switch if indication of the corre-

sponding switch is not light.

Run maintenance item U243 and select the original conveying

motor to be turned on and off. Check the status and remedy if

necessary.

Run maintenance item U243 and select the switchback feedshift

solenoid to be turned on and off. Check the status and remedy if

necessary.

Check visually and replace DP timing switch if its actuator is bro-

ken.

Run maintenance item U244 and turn DP timing switch on and

off manually. Replace DP timing switch if indication of the corre-

sponding switch is not light.

Run maintenance item U243 and select the original conveying

motor to be turned on and off. Check the status and remedy if

necessary.

Run maintenance item U243 and select the switchback feedshift

solenoid to be turned on and off. Check the status and remedy if

necessary.

Run maintenance item U244 and turn original switchback switch

on and off manually. Replace original switchback switch if indi-

cation of the corresponding switch is not light.

Run maintenance item U243 and select the original conveying

motor to be turned on and off. Check the status and remedy if

necessary.

Run maintenance item U243 and select the switchback feedshift

solenoid to be turned on and off. Check the status and remedy if

necessary.

Use only originals conforming to the specifications.

Clean with isopropyl alcohol.

Check and remedy.

*1: Optional. *2: Optional for 16 ppm model. Standard for 20 ppm model.

Summary of Contents for cd 1116

Page 1: ...Service Manual Copy CD 1116 CD 1120 Rev 1 ...

Page 2: ...Service Manual Copy DC 2116 DC 2120 Rev 1 ...

Page 4: ...This page is intentionally left blank ...

Page 247: ...2DA 2DB 1 2 3 2 Figure 2 3 2 Power source PCB silk screen diagram 220 240 V AC 120 V AC ...

Page 264: ...2DA 2DB 1 2 3 19 Figure 2 3 10 Operation unit PCB silk screen diagram ...