2DA/2DB

2-1-12

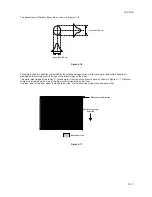

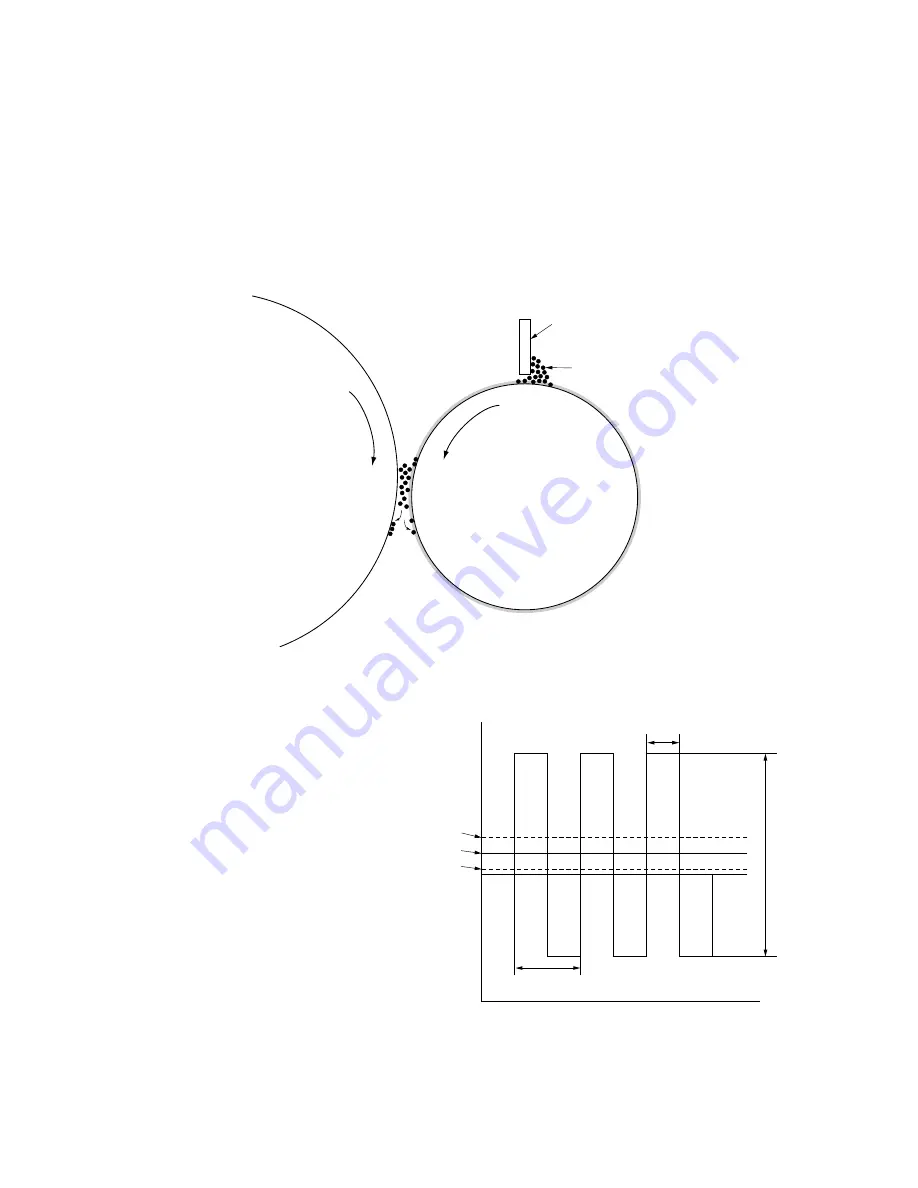

(2) Single component developing system

This machine uses the single component developing system, and reversal processing is performed with a + charged

drum (a-Si) and a + charged magnetic toner.

With the single component developing system, toner is electrically charged by friction with the developing sleeve and +

charged when it passes through the magnetic doctor blade. The toner that has passed through the magnetic doctor

blade forms a uniform layer on the developing sleeve. When the toner layer comes to the location where the developing

sleeve is the nearest to the drum, toner moves between the drum and the developing sleeve by an electric field of the

magnetic pole. Then, when the developing sleeve rotates and passes through the nearest location to the drum, on the

portion of the drum that has been exposed to light, toner is attracted toward the drum by potential difference between the

developing bias and the drum surface and development is performed. On the other hand, on the portion of the drum that

has not been exposed to light, toner is attracted toward the sleeve and development is not performed. When toner

comes to an area where the gap between the drum and the developing sleeve is large, an electric field disappears and

toner does not leave the developing sleeve. Development is complete.

North pole

South pole

Developing sleeve

Drum

Magnetic toner blade

Toner

Figure 2-1-13 Single component developing system

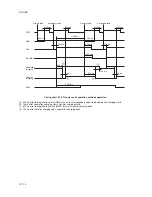

Developing bias parameters

For the bias to the developing sleeve, an alternating

current (AC) is applied. Parameters for the

developing bias are shown below.

Vp-p: Difference between the maximum and the

minimum of applied voltage

1.6 kV (fixed)

Vf: Frequency

Typically

2.7 kHz. This value varies depending on the

preset value of the drive time and the environmental

correction. (Can be adjusted with the maintenance

item U101.)

Duty: Ratio of time where + voltage is applied in a

cycle

Typically 45%. (Can be adjusted with the

maintenance item U101.)

Vdc: Developing shift bias potential 290 V

Supplementation

Vo: Drum surface potential on non-image area (area

not exposed to light)

VL: Drum surface potential on image area (area

exposed to light)

Vdc

Vo

Duty

Vf

Vp-p

VL

0

V

Figure 2-1-14 Developing bias waveformsa

Summary of Contents for cd 1116

Page 1: ...Service Manual Copy CD 1116 CD 1120 Rev 1 ...

Page 2: ...Service Manual Copy DC 2116 DC 2120 Rev 1 ...

Page 4: ...This page is intentionally left blank ...

Page 247: ...2DA 2DB 1 2 3 2 Figure 2 3 2 Power source PCB silk screen diagram 220 240 V AC 120 V AC ...

Page 264: ...2DA 2DB 1 2 3 19 Figure 2 3 10 Operation unit PCB silk screen diagram ...