2DA/2DB-1

2-3-1

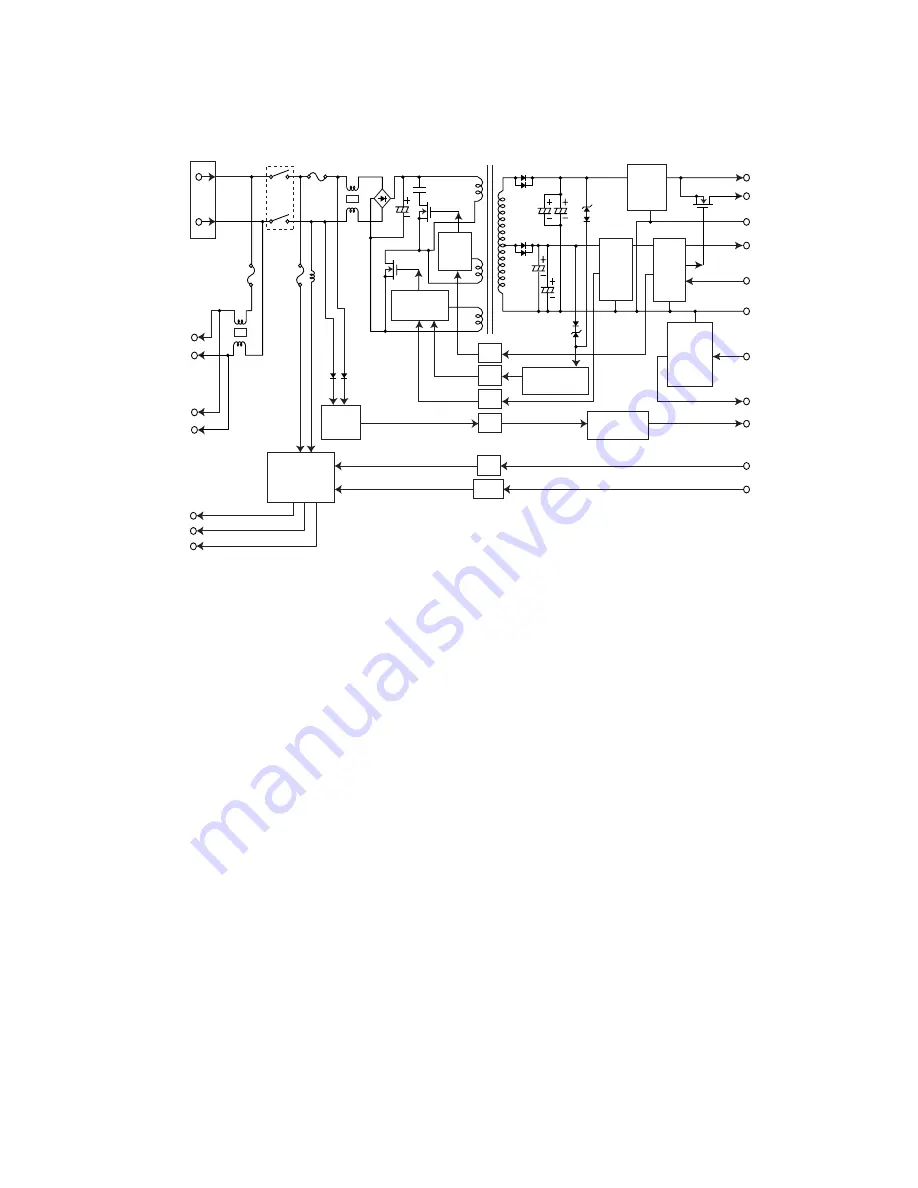

2-3-1 Power source PCB

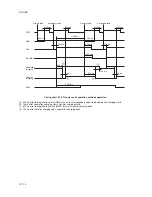

Figure 2-3-1

Power source PCB block diagram

The power source PCB (PSPCB) is a switching regulator that converts an AC input to generate 24 V DC and 5 V DC. It

includes a rectifier circuit, a switching regulator circuit, a 24 V DC output circuit, a 5 V DC output circuit, overvoltage

detection circuit, zero-cross circuit and a fixing heater control circuit.

The rectifier circuit full-wave rectifies the AC input using the diode bridge D1. The smoothing capacitor (C5) smoothes out

the pulsed current from the diode bridge.

In the switching control circuit, switching circuit turns the power MOSFET (Q1) on and off to switch the voltage induced in

the primary coil of the transformer (T1).

The 5 V DC output circuit rectifies and smoothes the voltage induced in the secondary coil of the transformer (T1) via diodes

(D102) and smoothing capacitors (C102, C105), and the output is controlled by the overvoltage detection circuit (IC101).

For 5 V DC output, the switching circuit of the switching control circuit changes the duty of the switching pulse width of the

power MOSFET (Q1) via a photo coupler (PC1) based on the output voltage status to adjust the 5 V DC output.

The 24 V DC output circuit rectifies and smoothes the voltage induced in the secondary coil of the transformer (T1) via

diodes (D101) and smoothing capacitors (C101, C104), and the output is controlled by the overvoltage detection circuit

(IC101).

The zero-cross circuit detects zero-crossing of the AC input voltage with the AC detection circuit and outputs the zero-cross

signal (ZCROSSC) from the zero-cross output circuit through the photo coupler (PC3).

The fixing heater control circuit is divided into the sub-heater output (SH.OUT) and the main heater output (MH.OUT). When

the control signals (SHEATN and MHEATN) input from the machine engine side show a low level, this circuit turns on the

sub-heater and the main heater respectively by turning on the photo triac couplers (PC2 and PC201) with a zero-cross

circuit to turn on the triacs (TRA1 and TR201) in the fixing heater ON/OFF circuit.

The power-saving control circuit performs power-saving control by turning off the 24 V DC output in the 24 V DC output ON/

OFF switching circuit and controlling the switching control circuit and the AC detection circuit through the photo coupler

(PC4) to decrease the switching frequency, stop the starting circuit in the switching control circuit, and stop the AC detection

circuit when the sleep signal (SLEPN) input from the machine engine side is low.

In addition, 5 V DC 3-terminal regulator (IC102) is connected to the back of the 24 V DC output ON/OFF switching circuit to

5 V1, and this output stops when the sleep signal (SLEPN) is low.

AC

INPUT

Zero-cross circuit

Rectifier circuit

CN1

DH1.LIVE

DH2.LIVE

DH1.OUT

DH2.OUT

SH.OUT

H.LIVE

MH.OUT

(TRA1,TR201)

D101

Q151

D1

D30

D109

D104

D111

D110

D33

T1

L2

L4

L3

L1

F1

F2

F3

Power switch

C101

C104

C5

C102

C105

Q1

Q2

D206

+24V

GND

GND

+5V

ZCROSSC

SHEATN

MHEATN

SLEPN

+24V1

+24V2

+5V1

Q153

Q154

IC101

PC1

PC5

PC4

PC3

PC2

PC201

24 V DC

output

circuit

5 V DC

3-terminal

regulator

(IC301)

Fixing heater

ON/OFF circuit

Fixing heater

control circuit

Energy

save

control

circuit

Energy

save

control

circuit

Zero-cross

output circuit

Switching

control circuit

Overvoltage

detection circuit

5 V DC

output

circuit

AC

detection

circuit

Summary of Contents for cd 1116

Page 1: ...Service Manual Copy CD 1116 CD 1120 Rev 1 ...

Page 2: ...Service Manual Copy DC 2116 DC 2120 Rev 1 ...

Page 4: ...This page is intentionally left blank ...

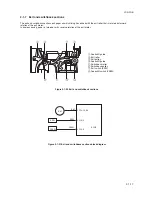

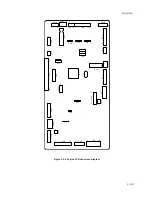

Page 247: ...2DA 2DB 1 2 3 2 Figure 2 3 2 Power source PCB silk screen diagram 220 240 V AC 120 V AC ...

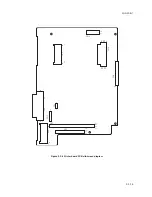

Page 264: ...2DA 2DB 1 2 3 19 Figure 2 3 10 Operation unit PCB silk screen diagram ...