3-5

Handling Paper

Smoothness

The paper should have a smooth, uncoated surface. Paper with a rough

or sandy surface can cause voids in the printed output. Paper that is too

smooth can cause multiple feeding and fogging problems. (Fogging is a

gray background effect.)

Basis Weight

Basis weight is the weight of paper expressed in grams per square meter

(g/m²). Paper that is too heavy or too light may cause feed errors or paper

jams as well as premature wear of the product. Uneven weight of paper,

namely uneven paper thickness may cause multiple-sheet feeding or

print quality problems such as blurring because of poor toner fusing.

The recommended basis weight is:

Cassette: 60 to 163 g/m

2

MP tray: 60 to 220 g/m

2

PF-520 (optional): 60 to 163 g/m

2

PF-530 (optional): 60 to 220 g/m

2

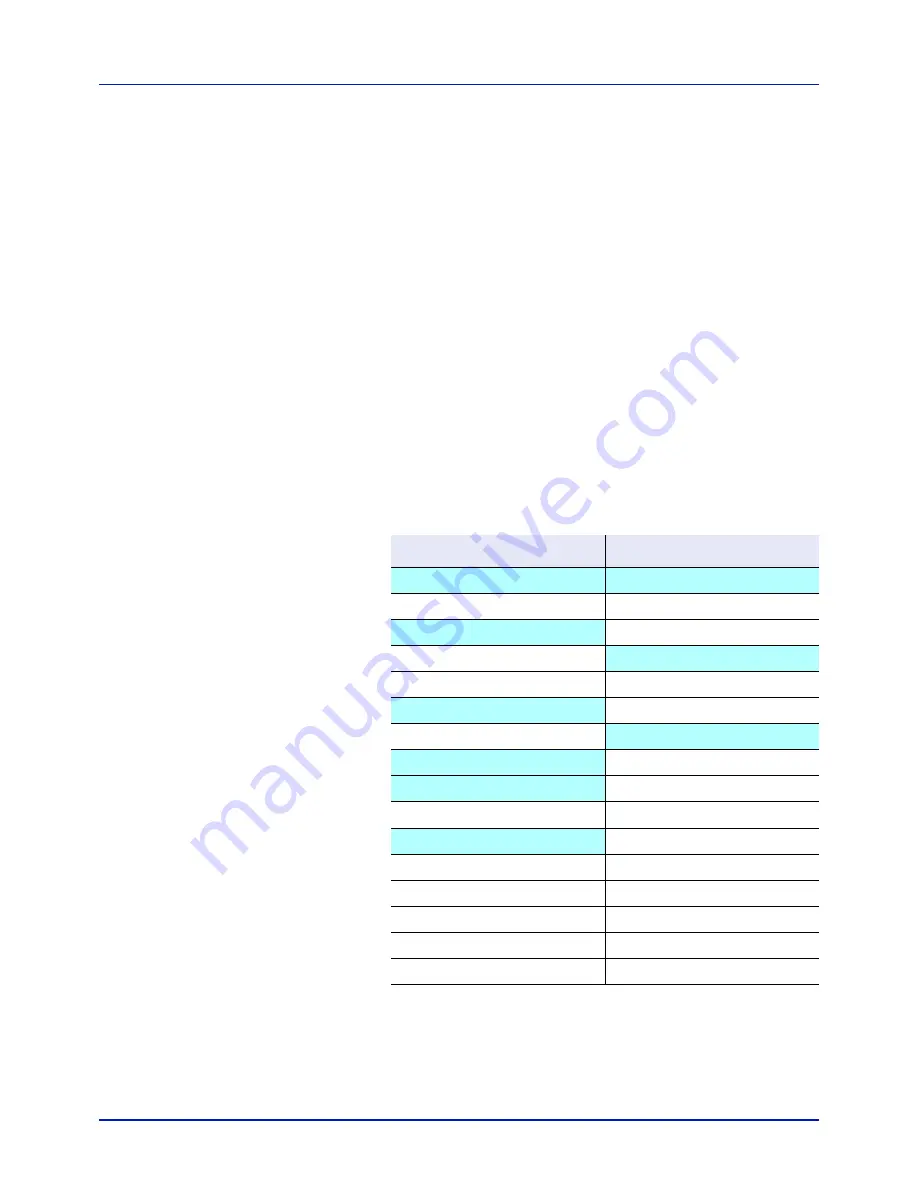

Paper Weight Equivalence Table

The paper weight is listed in pounds (lb) and metric grams per square

meter (g/m²). The shaded part indicates the standard weight.

Thickness

The paper used with the machine should be neither extremely thick nor

extremely thin. If you are having problems with paper jams, multiple

feeds, and faint printing, the paper you are using may be too thin. If you

U. S. Bond Weight (lb)

Europe Metric Weight (g/m²)

16

60

17

64

20

75

21

80

22

81

24

90

27

100

28

105

32

120

34

128

36

135

39

148

42

157

43

163

47

176

53

199

Summary of Contents for CLP 3721

Page 1: ...DOCUMENT CONSULTING instruction manual colour printer CLP 3721 3726 ...

Page 2: ......

Page 21: ...xviii ...

Page 41: ...Printing Operation 2 16 ...

Page 59: ...Handling Paper 3 18 ...

Page 149: ...Using the Operation Panel 4 90 ...

Page 173: ...Troubleshooting 6 16 ...

Page 187: ...Appendix A 14 ...

Page 191: ...Glossary Glossary 4 ...

Page 195: ...Index 4 ...

Page 196: ......

Page 197: ...UTAX GmbH Ohechaussee 235 22848 Norderstedt Germany ...