2GL/2FV/2FW

1-5-10

6050

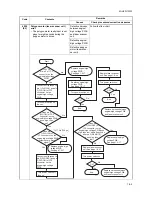

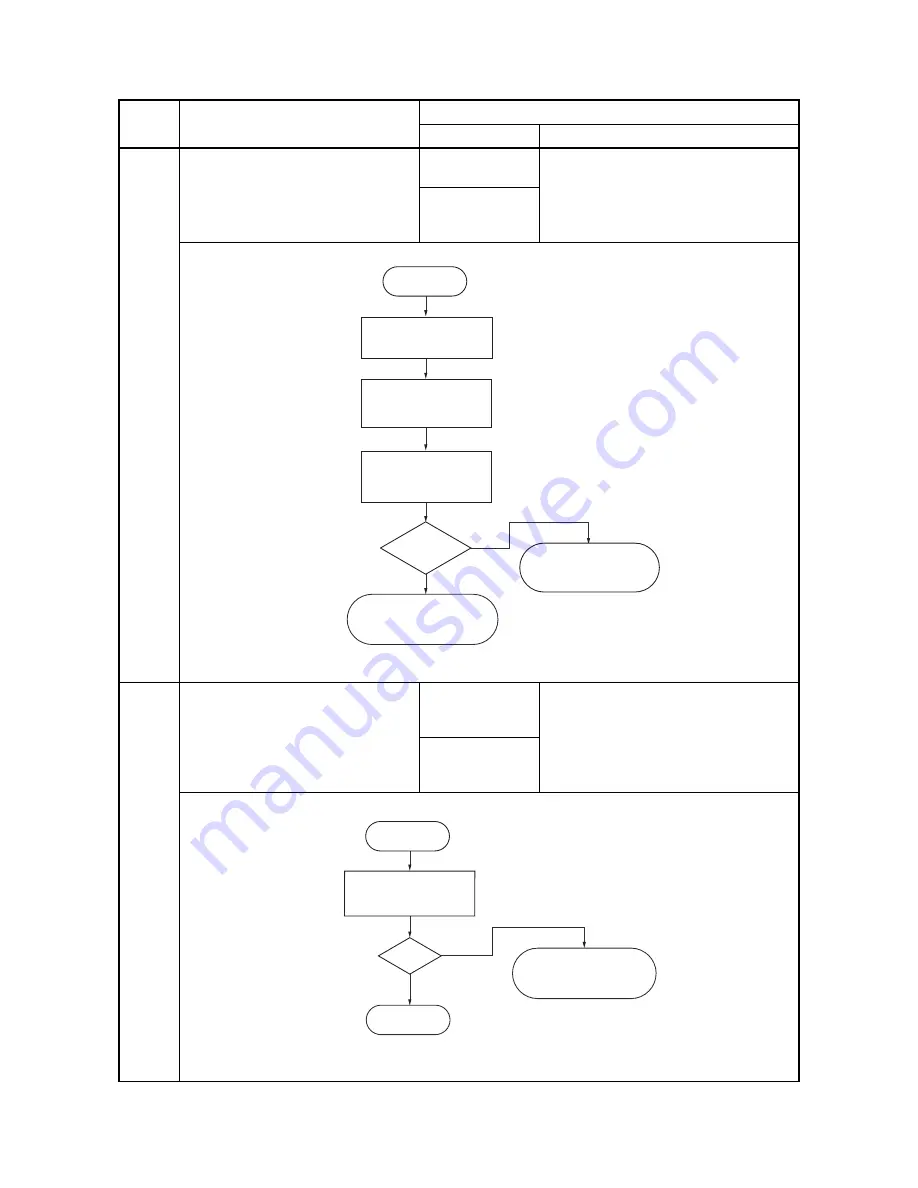

(E4)

Broken fuser thermistor

• The thermistor AD value is less than 1

for 3 s.

Defective the fuser

thermistor.

Follow the flow chart.

Defective the

engine/high volt-

age PWB.

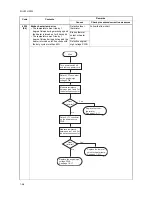

6400

(A0)

Zero cross signal error

• While fuser heater ON/OFF control is

performed, the zero-cross signal is not

input within 3 s.

Defective the

power source

PWB.

Follow the flow chart.

Defective the

engine/high volt-

age PWB.

Code

Contents

Remarks

Causes

Check procedures/corrective measures

No

Start

Yes

Replace engine/high

voltage PWB.

See page 1-6-17.

Replace fuser thermistor.

See page 1-6-11.

Turn power switch off,

and remove power cord.

Detach YC7 connector

on the engine/high

voltage PWB.

Measure resistance

between pins 1 and 2 of

the detached connector.

Open

(infinite)?

No

OK?

End.

Start

Yes

Replace the power

source PWB.

See page 1-6-17.

Replace the engine/high

voltage PWB.

See page 1-6-17.

Summary of Contents for LP 3118

Page 1: ...Service Manual Printer LP 3118 22 02 2005 ...

Page 2: ...Service Manual Printer LP 4118 22 02 2005 ...

Page 7: ...This page is intentionally left blank ...

Page 19: ...2GL 2FV 2FW 1 1 10 This page is intentionally left blank ...

Page 21: ...2GL 2FV 2FW 1 2 2 This page is intentionally left blank ...

Page 29: ...2GL 2FV 2FW 1 3 8 This page is intentionally left blank ...

Page 41: ...2GL 2FV 2FW 1 4 12 This page is intentionally left blank ...

Page 65: ...2GL 2FV 2FW 1 5 24 This page is intentionally left blank ...

Page 95: ...2GL 2FV 2FW 1 7 6 This page is intentionally left blank ...

Page 125: ...2GL 2FV 2FW 2 4 6 This page is intentionally left blank ...

Page 126: ......