3NF

2-3-2

Connector

Pin

Signal

I/O

Voltage

Description

YC3

1

PAP_R_SW1_P

W

O

1.2 V DC

1.2 V DC power output to PFPGS1(L)

Connected to

the PF paper

gauge sensor

1 lower, PF

paper gauge

sensor 1

upper, PF

size detec-

tion switch 1,

PF cassette

detection

switch 1.

2

GND

-

-

Ground

3

PAP_R_SW1

I

0/3.3 V DC

PFPGS1(L): On/Off

4

PAP_R_SW2_P

W

O

1.2 V DC

1.2 V DC power output to PFPGS1(U)

5

GND

-

-

Ground

6

PAP_R_SW2

I

0/3.3 V DC

PFPGS1(U): On/Off

7

NC

-

-

Not used

8

GND

-

-

Ground

9

NC

-

-

Not used

10

NC

-

-

Not used

11

GND

-

-

Ground

12

NC

-

-

Not used

13

SIZE_R_SW_P

W

O

1.2 V DC

1.2 V DC power output to PFSDSW1

14

GND

-

-

Ground

15

SIZE_R_SW

I

0/3.3 V DC

PFSDSW1: On/Off

16

DEK_R_SW1_P

W

O

1.2 V DC

1.2 V DC power output to PFCDSW1

17

GND

-

-

Ground

18

DEK_R_SW4

I

0/3.3 V DC

PFCDSW1: On/Off

YC4

1

EMPTY_L_SW_

PW

O

1.2 V DC

1.2 V DC power output to PFPS2

Connected to

the PF paper

sensor 2, PF

lift sensor 2,

PF feed sen-

sor 2, PF

paper con-

veying sen-

sor 2.

2

GND

-

-

Ground

3

EMPTY_L_SW

I

0/3.3 V DC

PFPS2: On/Off

4

LIMIT_L_SW_P

W

O

1.2 V DC

1.2 V DC power output to PFLS2

5

GND

-

-

Ground

6

LIMIT_L_SW

I

0/3.3 V DC

PFLS2: On/Off

7

3.3V3

O

3.3 V DC

3.3 V DC power output to PFFS2

8

FD_L_SW

I

0/3.3 V DC

PFFS2: On/Off

9

GND

-

-

Ground

10

VFDSW_PW

O

1.2 V DC

1.2 V DC power output to PFPCS2

11

GND

-

-

Ground

12

VFDSW

I

0/3.3 V DC

PFPCS2: On/Off

Summary of Contents for PF 740

Page 1: ...Service Manual Paper Feeder 3 PF 740B Rev 2 0 Date 28 10 2013 3NFSM062 ...

Page 2: ...Service Manual Paper Feeder 3 PF 740B Rev 2 0 Date 28 05 2013 3NFSM062 ...

Page 5: ...This page is intentionally left blank ...

Page 11: ...This page is intentionally left blank ...

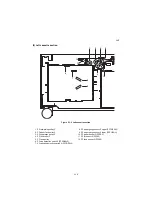

Page 16: ...3NF 1 1 3 1 1 3 Machine cross section Figure 1 1 2 Paper path ...

Page 17: ...3NF 1 1 4 This page is intentionally left blank ...

Page 57: ...3NF 1 3 30 This page is intentionally left blank ...

Page 99: ...3NF 2 2 4 This page is intentionally left blank ...

Page 105: ...3NF 2 3 6 This page is intentionally left blank ...

Page 109: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR LARGE CAPACITY FEEDER ...