7.1

95-8533

5-7

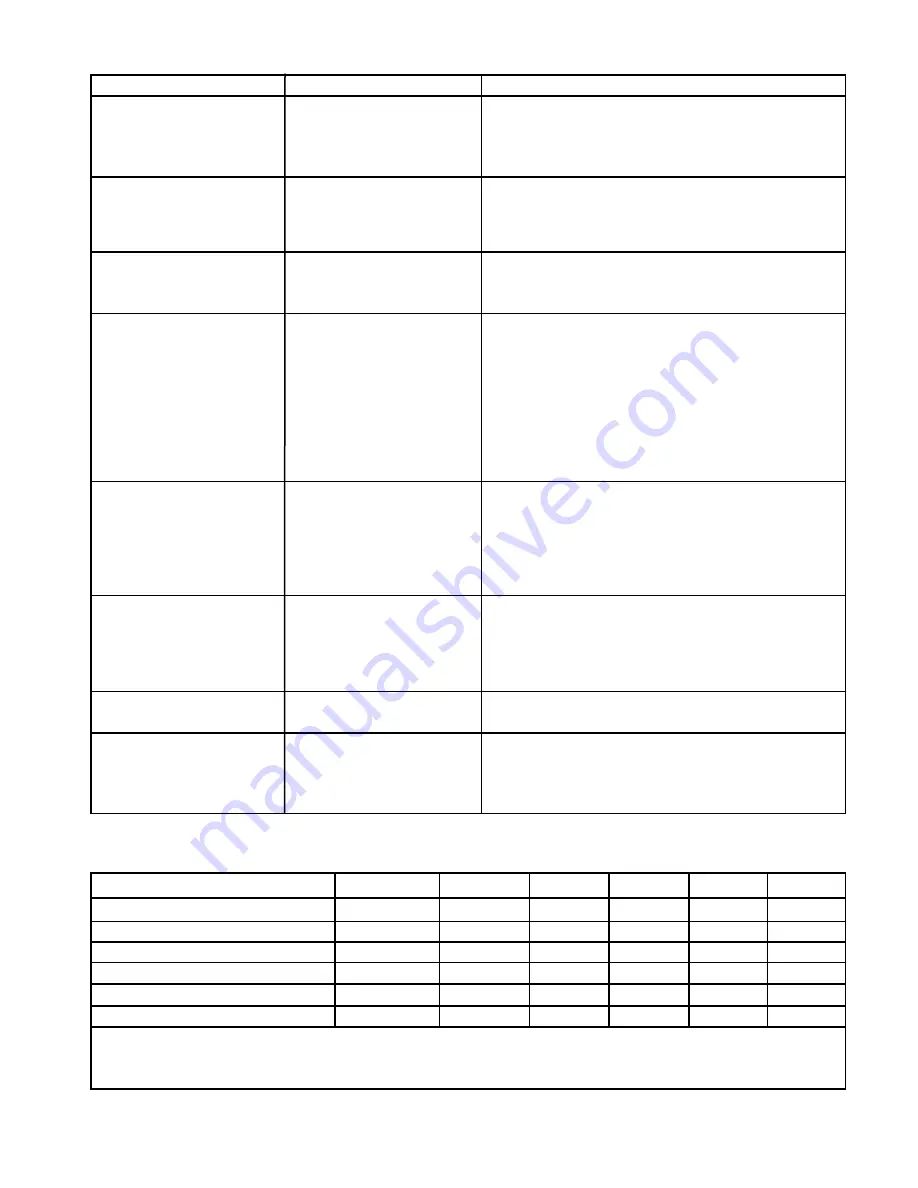

Table 5-1—System Controller Troubleshooting Guide

Symptom

Possible Cause

Corrective Action

Controller Power LED/

No Power to Input.

- Measure input voltage (18 to 32 VDC).

Text Display OFF.

- Check that P1 is fully inserted.

If voltage is present and P1 is fully inserted, replace

controller.

LON Fault – LED lit.

LON wiring is shorted or open. - Check that P7 is fully inserted.

- Using the EQ Safety System Software, determine the

location of open or short via LON Diagnostics screen.

- Use a multimeter to determine wiring fault.

Trouble Relay is Active.

Any monitored device in the

- Using the front panel display/controls, view all points

system including ground fault

in alarm/fault and identify faulted device.

in fault condition.

Repair or replace faulted device as necessary.

Digital inputs are not

- Bad input switch.

- Check that P2 and P3 are fully inserted.

responding.

- Faulty input channel.

- Using a voltmeter, measure input terminals with contact

- Faulty wiring.

closed to the input (measures 0 vdc when input contact

- Configuration error.

is closed, measures approximately 23 vdc with circuit

open and 24 vdc input at the controller).

- If input does not respond to a contact closure, replace

module (verify response with EQ Safety System

Software/textual display).

- Verify configuration.

Relay outputs are not

- Bad relay channel.

- Check that P4 and P5 are fully inserted.

responding to an output

- Faulty output wiring.

- When output should be energized, measure contact

command.

- User logic.

resistance using an ohm meter.

- Verify that wiring from output is not open.

- Using EQ Safety System Software, verify that logic is

trying to operate the channel.

Serial links are not responding. - Faulty wiring.

- Check that P8 and P9 are fully inserted.

- Incorrect serial link

- Verify that communication LEDs are flashing.

configuration.

- Verify that serial link configuration matches the host

- Text display shows

device.

“Invalid Configuration”

- Verify that wiring is not open or shorted.

Front panel pushbuttons are

- Power OFF.

- Verify that power is present and P1 is fully inserted.

not working.

- Controller is faulted.

- Cycle power to controller.

Text display indicates a

Power loss for more than

- Using the Safety System Software, execute “Set RTC”,

RTC Fault.

12 hours.

which downloads the current time into the Controller’s

real time clock. Alternatively, use the “Set Time and

Date” menu in the Controller.

Table 5-2—Troubleshooting Guide - DCIO Module

I/O Type

Normal (Off)

Normal (On) Open (Off) Open (On) Short (Off) Short (On)

Unsupervised Input

–15.4

0

–15.4

–15.4

0

0

Supervised Input (EOL Resistor)

–14.4

0

–15.4

–15.4

0

0

Supervised Input (EOL/Inline Resistors)

–15.4

–15

–15.4

–15.4

0

0

Unsupervised Output

–15.4

23.9

–15.4

23.9

0

0

Supervised Output (Agent Release)

0 to 2.1 Note 2

23.9

–15.4

23.9

0

0

Supervised Output (Notification)

–14.4

23.9

–15.4

23.9

0

0

Notes:

1. All measurements are in Volts and are measured in reference to the common terminal and 24.0 Vdc is the module’s input.

2. Value is dependent on the resistance of the solenoid attached.

Summary of Contents for DET-TRONICS 95-8533

Page 128: ...7 1 95 8533 A 4 Figure A 1 System Drawing 007545 001 ...

Page 129: ...95 8533 A 5 7 1 Figure A 2 System Drawing 007545 001 ...

Page 131: ...95 8533 7 1 B 2 Figure B 1 Drawing 007546 001 ...

Page 132: ...95 8533 7 1 B 3 Figure B 2 Drawing 007546 001 ...

Page 134: ...95 8533 7 1 C 2 Figure C 1 Drawing 007547 001 ...

Page 141: ...95 8533 7 1 D 7 Figure D1 System Drawing 007545 001 ...

Page 143: ...APPENDIX E E 1 95 8533 7 1 ...