10

V - CHECKOUT PROCEDURES AND ADjUSTMENTS

Drill a ½” hole in the plastic CPVC vent pipe or exhaust

2.

tee, just large enough to allow access for the sample

probe of your combustion analyzer.

Turn the thermostat to the closed position so the appli

-

3.

ance is activated.

Set appliance to high fire mode as described in the

4.

“User Interface Quick Reference” section of this manual

and allow it to run for approximately 5 minutes.

Insert the sample probe of your combustion analyzer

5.

into the hole you drilled in Step 2 about halfway into

the exhaust gas stream. Take a flue gas reading and

observe the % CO2 and CO values. Adjust the throttle

screw until the correct readings are reached. turning

the throttle screw clockwise decreases the rate and the

Co2 value. turning the throttle screw counter clockwise

increases the rate and the Co2 value. allow the ap-

pliance to stabilize for approximately one minute after

adjusting the throttle screw before you take a reading

with your combustion analyzer.

IMPORTANT: Under all conditions CO levels

should not exceed 80 ppm.

Set appliance to low fire mode as described in the “User

6.

Interface Quick Reference” section of this manual and

check CO2 level as stated in Step 5. Low fire and high

fire values should be approximately the same.

After adjustments are made stop the appliance, dis

-

7.

connect the pressure gauge, tighten the inlet pressure

tap on the gas valve, remove the CO2 meter from the

CPVC pipe, and seal the hole with a ¼” NPT black iron

plug. Use thread sealing compound or teflon tape to

ensure a proper seal.

Return the thermostat switch to its original position.

8.

Installers: Complete and sign the “Installa-

tion and Checkout Certificate” on the last page

of this manual.

MEASURE THE NATURAL GAS INPUT RATE

Correct input rate is essential for proper and efficient

operation of the burner and boiler.

Determine the elevation at the installation site.

1.

See Table 2 in Section IV of the separate “Installation

2.

Manual” (P/N# 240006103) to determine the correct ap

-

proximate input rate for the local elevation.

Obtain the yearly average heating value of the local gas

3.

utility. At sea level elevation, it should be approximately

1000 BTU per standard cubic foot.

Operate boiler for 5 minutes.

4.

Turn off all other gas appliances, extinguishing standing

5.

pilots where applicable.

At the gas meter, measure the time in seconds required

6.

to use one cubic foot of gas.

NOTE:

Boiler must be in high fire mode for this operation.

See the “User Interface Quick Reference” in this manual for

more information on putting the boiler in high fire mode.

Calculate the BTUH Input Rate as follows:

7.

Btuh input rate =

3600 x heating value from Step 3

16 +/- 2 seconds

The measured input rate will vary with vent length, gas

8.

calorific content, altitude and ambient temperature. The

boiler should be set up with the combustion specifica

-

tions in the “Boiler Adjustment” section.

DETERMINE LP GAS INPUT RATE

LP gas input rate is determined by measuring the C0

2

produced during combustion. This value should be

set according to the guidelines table on the following

page.

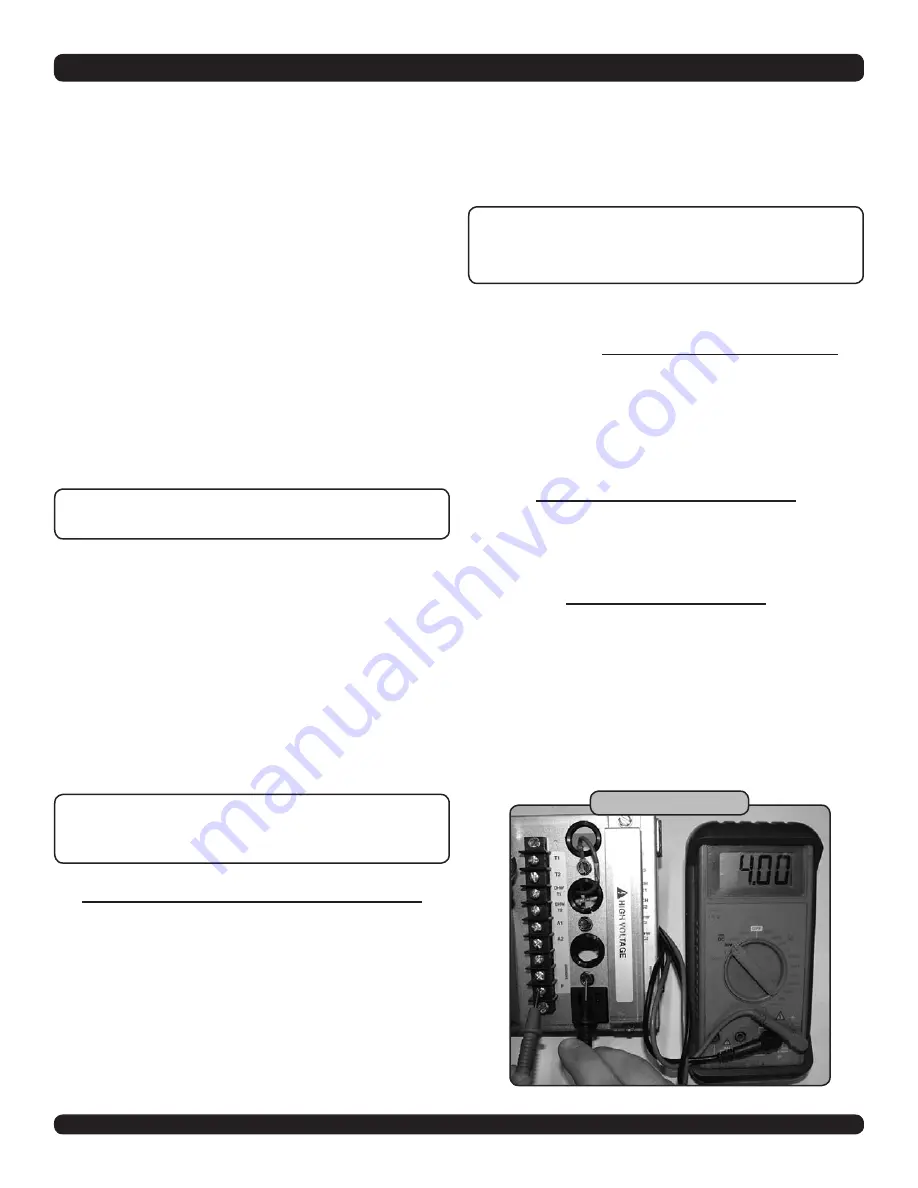

MEASURE FLAME SENSE

Flame sense can be an indicator of issues with air in

-

take venting, exhaust venting, burner and ignitor con

-

dition and supply gas piping pressure. Using a multim

-

eter capable of reading 0-20 VDC, attach one lead to

the “F” terminal on the low voltage terminal block on

the boiler control, and the other to any ground surface

on the boiler. See Figure #2. The flame sense voltage

must be in accordance with the values listed in the

Flame Signal Guidelines chart later in this manual.

Figure #2