14

WHAt tO DO IF YOu sMeLL GAs

do not try to light any appliance.

•

do not use any electrical appliance.

•

do not touch any electrical switches; do not use

•

any phones in your building.

Immediately call your gas supplier from a neigh

-

•

bor’s phone. Follow the gas supplier’s instruc

-

tions. if you cannot reach your gas supplier, call

the fire department.

Should overheating occur or the gas supply fail

to shut off, do not turn off or disconnect the

electrical supply to the pump. Instead, shut off

the gas at a location external to the appliance

Do not use the boiler if any part of the gas con-

trol system has been underwater. A qualified

service technician should inspect the boiler

and replace any part of the control system and

any gas control which has been underwater.

Use only your hand to turn the gas control

knob. Never use tools. If the knob will not turn

by hand, don’t try to repair it. Force or attempt-

ed repair may result in a fire or explosion.

Electrical shock may cause serious injury or

death. The following procedures may expose

you to dangerous line voltage so use caution

to avoid touching live electrical contacts. All

service must be performed by a trained, experi-

enced service technician.

VIII - TROUBLESHOOTING

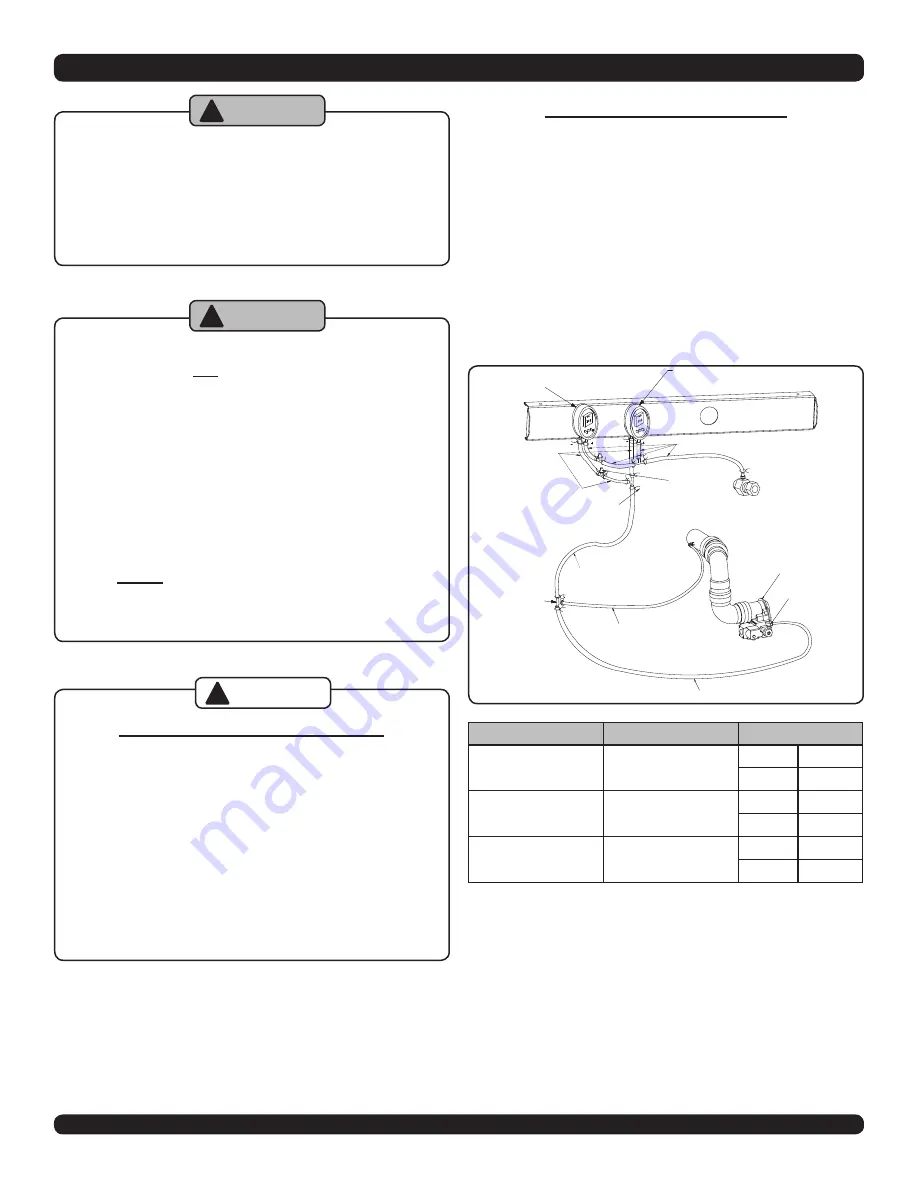

DIFFERENTIAL AIR PRESSURE

the differential air pressure switch is a safety device

which will prevent the boiler from firing if there is an air

intake, boiler heat exchanger or vent blockage.

To check the differential air pressure:

Turn off service switch or lower thermostat setting.

1.

Remove vinyl caps from tee.

2.

Install testing lines as shown to inclined manometer or

3.

differential pressure gauge with the ability to read 0.01”

increments to at least 6.0” w.c.

Turn on service switch and set thermostat to call for

4.

heat.

Boiler Status

Diff. Pressure

Switch Contacts

not running

0”

3.5”

Closed

0.14”

open

running with

Blockage

greater than or

equal to setpoints

3.5”

open

0.14”

Closed

Running w/out

Blockage (approx.)

Min. Fire: 0.3”

3.5”

Closed

Max. Fire: 2”

0.14”

Closed

If manometer readings do not correspond to the chart above, check

for possible causes:

• Blockage or moisture in suction lines to switch.

• Blockage in air intake or vent pipes.

• Undersized air intake or vent pipes.

• Loose blower wheel on motor shaft.

• Incorrect pressure switch or pressure switch setpoint

When pressure reading is proper and the pressure switch is

operating properly, remove testing lines and reinstall vinyl caps to

tee and 3-way connector.

1500010 - SW PRESS NORM

OPEN SET PT .04”/0.14”

YELLOW LABEL

1552004 - TUBE, ORANGE,

3/16” X 5/16” OD SILICONE

1552004 - TUBE, ORANGE,

3/16” X 5/16” OD SILICONE

1230006 - CAP

BLK VINYL 3/16”

2 REQ’D

1552014 - TUBE

SILICONE, 3/16” ID

1500011 - SW PRESS NORM

CLOSED SET PT 3.5”

WHITE LABEL

GAS VALVE

PB-002.02 - ORIFICE PILOT

390686-1 HW-LP BBR10

1552004 - TUBE, ORANGE,

3/16” X 5/16” OD SILICONE

1552004 - TUBE, ORANGE,

3/16” X 5/16” OD SILICONE

1110001 - CLAMP ROTOR

HC-5ST-R, 22 REQ’D

AIR INLET

CONNECTION

151009 - TEE PLASTIC

BARBED HOSE, 3/16” ID

5 REQ’D

WARNING

!

WARNING

!

CAUTION

!