19

VIII - TROUBLESHOOTING

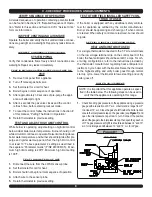

HARD LOCKOUT

(Display flashes first digit “E” and last two digits (code))

Code

Reason For Hard Lockout

Corrective Actions

(pressing RESET should restart boiler immediately):

WARNING:

Electrical shock hazard. Turn off power to boiler when working with wiring or replacing any boiler component.

09

internal control failure.

1

Reset control and retry. If problem persists, replace control module.

11

12

Casting temperature switch opened.

1

Determine reason for limit action and correct. Check for air trapped at top of casting.

2

If limits are closed, check wiring and connections. Apply a temporary jumper across

terminals 6 and 8 and check operation. If problem persists, check boiler internal

wiring. Replace low voltage harness if necessary. Replace control module if harness

replacement doesn’t resolve.

13

thru

17

internal control failure.

1

Reset control and retry. If problem persists, replace control module.

18

Thermal Overrun Condition:

outlet

water temp. above 200 °F

1

Check system for:

Verify boiler and system are full of water.

•

Make sure system does not have trapped air.

•

Inspect and verify system piping and components.

•

Make sure water flow is not reversed or pipes crossed.

•

2

Use contact thermometer to check outlet water temp. Compare to temp. shown with

display in “INFO” mode (

“1”

in first digit). Replace return temp. sensor if results are

not close. Replace control module if sensor replacement doesn’t solve problem.

19

Thermal

Overrun

Condition:

Return water temp. above 190 °F

1

See Code 18, Corrective Action#1 (above).

2

Use contact thermometer to check return water temp. Compare to temp. shown with

display in “INFO” mode (

“2”

in first digit). Replace return temp. sensor if results are

not close. Replace control module if sensor replacement doesn’t solve problem.

28

Blower not running.

1

Turn off power to boiler. Remove line voltage connector at blower. Restart boiler

and check voltage across blower plug terminals. If 120 vac is

NOT

present, inspect

wiring and tightness of connections. replace line voltage wire harness if necessary.

Replace control module if wire harness replacement doesn’t resolve.

2

If 120 vac is present on blower wire harness, replace harness and retry. If problem

persists, replace blower motor.

29

Blower signal not 0 when it should

be.

1

Inspect wiring and connections. If wiring is correct, replace blower assembly. If

blower assembly replacement is unsuccessful, replace control module.

30

Temp difference between supply & return,

indicated by blocking code b30, was

too large for 20 successive times. Non

adjustable default Max Delta set to 100°F

1

Inspect supply & return water sensors for proper resistance.

2

Inspect piping for proper configuration. For example, when used in a radiant

heating application.

31

Outlet water temp. short circuit.

1

Inspect outlet water temp. sensor and wiring. Replace sensor if wiring correct and

in good condition. Replace low voltage wiring harness if problem persists. Replace

control module if harness replacement doesn’t resolve.

32

Return water temp. short circuit.

1

Inspect return water temp. sensor and wiring. Replace sensor if wiring correct and

in good condition. Replace low voltage wiring harness if problem persists. Replace

control module if harness replacement doesn’t resolve.

36

Supply water temp. sensor open

circuit.

1

See Corrective Action# 1 under Code 31 (above)

37

Return water temp. sensor open

circuit.

1

See Corrective Action# 1 under Code 32 (above)

44

internal control failure.

1

Rest control and retry. If problem persists, replace control module.

60

61

65

Blower signal too low (not enough

driving force).

1

Inspect wiring and connections. If wiring is correct, replace blower assembly. If

blower assembly replacement is unsuccessful, replace control module.