25

B. Ignition failure

- with burner off, close oil supply

valve and run through start-up procedure, The safety

switch should lock out as in flame failure.

C. Power failure

- Turn off main power supply switch

while burner is operating� When burner stops, restore

power and burner should start�

If operation is not as described as above, check

wiring and controls�

14.6 Preventive Maintenance

-

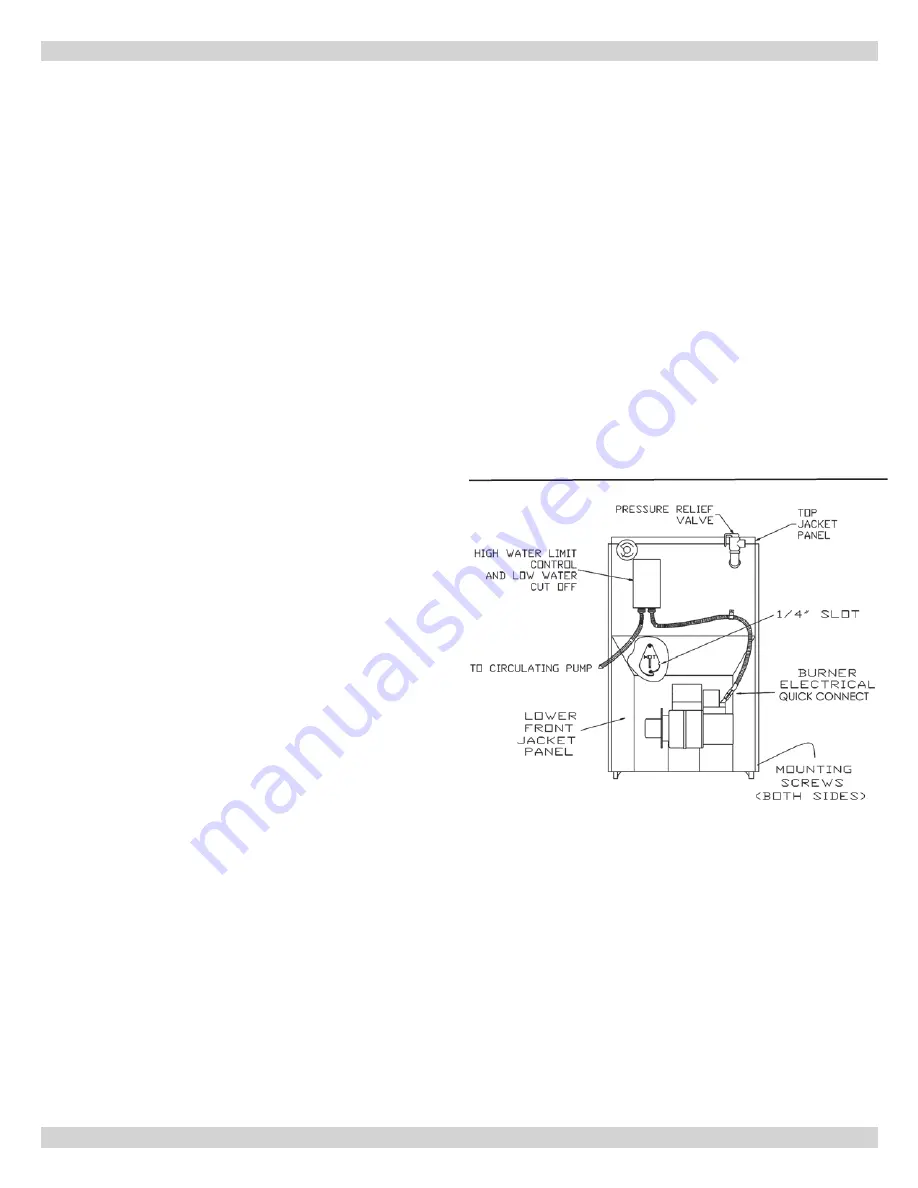

Inspect boiler and vent pipe for accumulation of soot or

scale deposits periodically, at least once every year before

start of each heating season� When soot is present on

section walls and flueways, improper combustion will result,

causing additional sooting and scaling until flueways are

completely closed. To remove soot and scale from flueways,

remove top jacket panel, top clean-out plate, open burner

swing door� See Figure #22�

Periodic inspection and tightening of tankless heater/cover

plate bolts will reduce risk of leaks�

14.7 Instructions For Opening Burner Swing

Door

1.

Turn off power to boiler.

2.

Allow boiler to cool down�

3.

Disconnect power cable at burner electrical quick

connect� See Figure #22.

4.

Loosen screws on the sides of lower front jacket panel�

5.

Pull bottom part of lower front panel forward�

6.

Lift lower front panel up and off boiler.

14 - OPERATING INSTRUCTIONS

7.

Close oil shutoff valve. See

Figures #17 & #18�

8.

Disconnect oil line from burner�

9.

Do not try to swing door with oil line attached�

10.

Remove nut from swing door stud on right hand side of

door�

11.

Swing open burner and door to the left�

14.8 Instructions For Closing Burner Swing Door

1.

Swing burner and door to right until insulation is

slightly compressed and stud is exposed�

2.

Attach nut to stud and tighten until built in stop

contacts the mounting door�

3.

Replace oil line to burner�

4.

Replace lower jacket panel, and tighten screws�

5.

Connect power cable at burner electrical quick connect�

6.

Turn on power to boiler. Open oil shutoff valve.

7.

Bleed oil line�

Figure #22

14.9 Start of Heating System

•

Using flue brush, brush soot and scale into combustion

space where it can be removed through swing door

opening�

• It is recommended to replace nozzle at start of each

heating season�

• Lubricate burner motor and circulator motor - if

required - with few drops of good grade light motor oil�

Do not over oil�

• Have service agent service burner, check controls and

check electrodes for carbon or cracks in insulators�

• Set burners to produce conditions shown in Start-up

and Adjustment of Oil Burner procedure as stated in

this section�

• Use caution when vacuuming in chamber area� Damage

to chamber could result�

PN 240013073, Rev. A [08/31/2020]