38

9.4 Boiler Start-up and Operational Test

1.

Verify air is purged from hydronic piping

2.

System test pumps - verify each pump is

operational

3.

Verify gas piping

•

Confirm pressure test. See section 7.3 page 33.

• Visually inspect piping to determine there are no

open fittings or ends, and all valves at unused

outlets are closed and plugged/capped.

• Purge air from piping

• Check piping and connections for leaks

immediately after gas is turned on. Shut off

gas supply and make necessary repairs if leaks

found.

4.

Follow OPERATING INSTRUCTIONS to initiate boiler

operation. See section 10.

5.

Inspect combustion air and vent piping. Verify pipe

is not leaking and terminations are unobstructed

and vent gas discharge is not a nuisance or hazard.

6.

Verify boiler functions.

7.

Inspect condensate disposal system. Verify

condensate flows adequately and is disposed

properly.

8.

Check control module operation.

9.

Check field sourced limits, low water cutoffs, etc.

per manufacturer's instructions.

9 - START UP PROCEDURE

9.5 Check Firing Rate

1.

Measure input, if a gas meter is installed in the

system.

• Turn off gas to all other appliances.

• Activate some heating zones to dissipate heat.

•

Set boiler on high fire.

• Use ½, 1 or 2 cu ft dial on gas meter. Measure

time required for two or more complete

revolutions. Measure time for one or more

minutes.

• Calculate input.

For Natural Gas :

Input (MBH)

=

3600 x cu ft

seconds

Example: Natural Gas - Gas flow from

Meter = 2 cu ft

Measured time = 72 seconds

Rate (MBH)

=

3600 x 2 cu ft

= 100 MBH

72 seconds

For Propane (LP):

Input (MBH)

=

9160 x cu ft

seconds

For Metric formulas- See Glossary

2.

Compare measured input to Table 11. If calculated

input is not in range given in Table 11, check firing

rate again after setting the combustion following

steps in section 9.6.

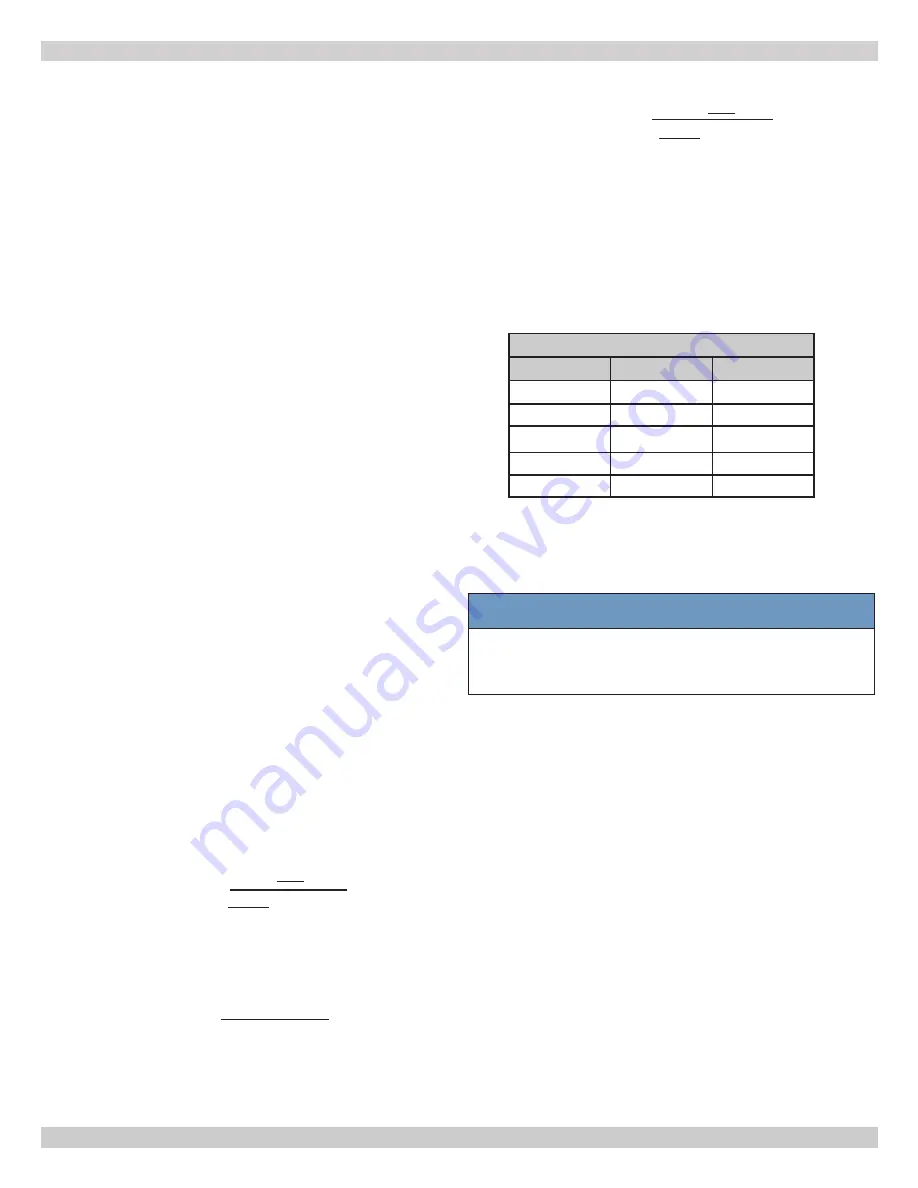

Table 11 - Rate @ High Fire

Rate @ High Fire

Size

From

To

050

45

51

075

65

76

100

90

102

150

140

153

200

185

204

9.6 Combustion Adjustment

Calibrated Combustion Analyzer is necessary for the

following combustion adjusment.

NOTICE

Before setting combustion in HIGH fire, activate all

heating zones to dump heat generated by the boiler

running on high fire.

1.

Enter installer menu (Enter + Menu buttons for 4

seconds).

A. Scroll down to System Test.

B. Push Enter button to enter System Test. When

“System Test Off” displays, push Enter button and

“Off” will start flashing.

C. Scroll up to High Power and push Enter. “High

Power” will stop flashing and becomes solid.

D.

Unit is now locked in high fire.

P/N# 240010615, Rev. E [07/2015]

Summary of Contents for SSV-050

Page 50: ...50 13 TROUBLE SHOOTING P N 240010615 Rev E 07 2015 ...

Page 52: ...52 13 TROUBLE SHOOTING P N 240010615 Rev E 07 2015 ...

Page 64: ...64 14 1 Connection Diagram 050 075 100 MBH 14 WIRING DIAGRAM P N 240010615 Rev E 07 2015 ...

Page 66: ...66 14 3 Connection Diagram 150 200 MBH 14 WIRING DIAGRAM P N 240010615 Rev E 07 2015 ...