17

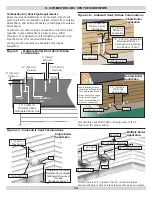

Connections And Termination

Installation must conform to requirements of authority

having jurisdiction or, in absence of such requirements,

to the section for Air for Combustion and Ventilation of

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/

or Natural Gas and Propane Installation Code, CAN/CSA

B149.1.

Installer must clean and remove all shavings from interior

of all pipes used on air intake to prevent damage to gas

burner and ensure proper operation.

Boilers require dedicated direct vent system. All air for

combustion is taken directly from outdoors through

combustion air intake pipe. All flue products are discharged

to outdoors through vent pipe. Install vent system in

accordance with instructions in this manual.

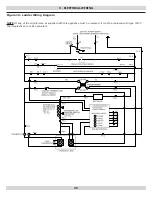

1.

Figures 8 and 9 “Combustion Air and Vent Pipe

Requirements, for standard two-pipe roof and sidewall

terminations and Figures 10, 11, and 12 for concentric

vent terminations (roof termination is preferred).

Combustion air and vent pipes must terminate together in

same atmospheric pressure zone as shown. Construction

through which vent and air intake pipes may be installed

is minimum ¼” and maximum 24” thickness.

2.

Combustion air and vent pipe fittings must conform

to one of the following American National Standards

Institute (ANSI) and American Society for Testing and

Materials (ASTM) standards:

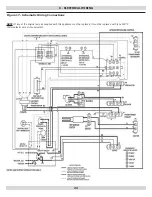

3.

Combustion air and vent piping connections on boiler

are 2”, but must increase to 3”. Due to potential for

flue gas temperatures over 155°F, first 5 feet of vent

pipe must be CPVC (furnished), remaining vent pipe

can be PVC. This requirement is not required when

using PP. If any elbows are employed within first 2½’

of vent, they must be CPVC. Two 30” pieces of 2” CPVC

pipe and one 2” CPVC coupling are furnished with

boiler. See Figure 13.

Length of pipe is counted from boiler jacket (air intake

pipe) or from vent tee (vent pipe). First five feet of “Total

Equivalent Length” of vent pipe must be CPVC. This

requirement is required when using PP.

Reduce maximum vent length 5 feet per each additional

elbow.

4.

Pitch horizontal combustion air and vent piping back

to boiler at minimum ¼” per foot (21mm/m) from

intake and vent terminals so all moisture in combustion

air and vent piping drains to boiler. Pitch pipes

continuously with no sags or low spots where moisture

can accumulate and block flow of air or flue gas. This

blockage may cause combustion instability, noise and

lead to nuisance control lockouts.

5.

Combustion air and vent pipes must be airtight,

watertight and tested for leaks.

7 - COMBUSTION AIR AND VENT PIPE

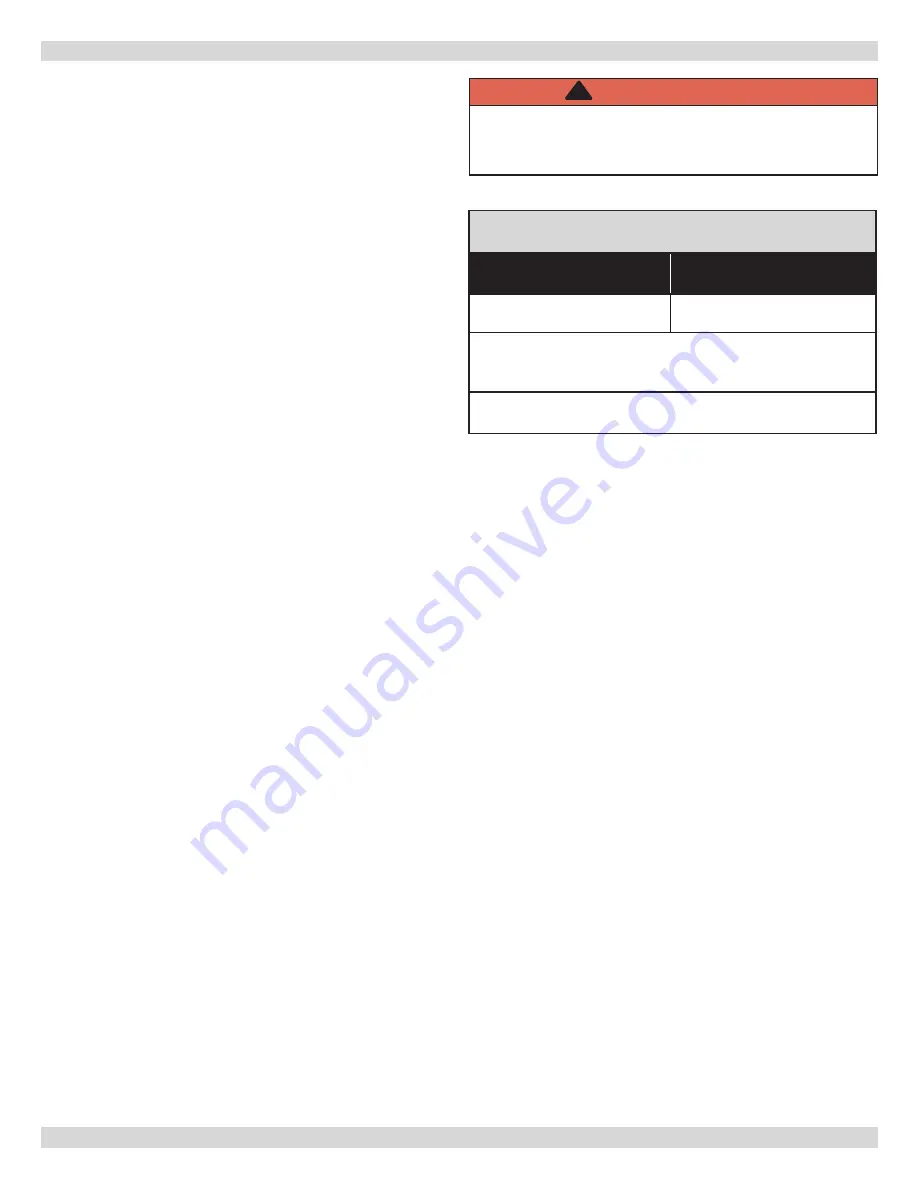

WARNING

Use of cellular core PVC (ASTM F891), cellular core

CPVC, or Radel

®

(polypenolsulfone) in venting

system could result in death, serious injury.

!

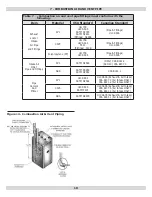

Table 6 Combustion Air and Vent Pipe

Length Requirement

3 in. Pipe

Minimum Venting

* 3 in. Pipe

Maximum Venting

6 ft. (1.8 m) in length

60 ft. (18.3 m) in length and

up to four (4) 90° elbows

1 - 90° elbow = 5 ft (1.6 m)

1 - 45° elbow = 3.5 ft (1.1 m)

1- 2” x 3” adapter = 0 ft (0 m)

All field installed vent pipe must be 3”

* Past first 2” section provided with boiler