8

General Instructions

1.

Packaged boiler is furnished with iron piping in front

boiler section for supply and return connections.

2.

Install all of radiation units (panels, radiators,

baseboard, or tubing) and supply and return mains

first, when installation of boiler is for new heating

system.

3.

After installation of all heating system piping and

components; make final connection of system piping to

boiler.

4.

Hot water boiler installed above radiation level or

as required by authority having jurisdiction must be

equipped with low water cut off device (included with

boiler).

5.

Periodic inspection is necessary, as is flushing of float

type devices, per low water cut off manufacturers

specific instructions.

6.

Proper water flow through any boiler is essential to

proper operation and long life. Simple single or two

zone systems with adequate flow do not require

primary secondary piping. Systems with more zones or

low flow require primary secondary piping.

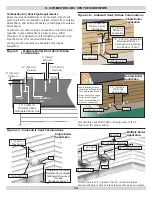

4 - NEAR BOILER PIPING

Dielectric Isolation

1.

Two (2) 1-1/4” X 1-1/4” female to female dielectric

isolation unions are supplied. Install dielectric isolation

unions at boiler supply line and return line. Install

isolation fittings nearest boiler prior to system piping

connections.

2.

Water contaminants that cause low or high pH makes

corrosion more likely.

3.

Do not install copper supply and return piping directly

into aluminum boiler section castings due to galvanic

corrosion between dissimilar metals.

4.

Use iron, steel bushings or pipe connectors between

copper system piping and boiler to make final

connection to boiler.

5.

Use of dielectric unions is required, supplied with boiler,

the purpose is to electrically insulate aluminum boiler

from remainder of the system.

Figure 2

- General Primary Secondary Configuration