GAS COMPRESSORS / BOOSTERS

GAS & AIR MIXING SYSTEMS

AIR BLOWERS & VACUUM PUMPS

The Utile Engineering Co. Ltd.

Irthlingborough, Northamptonshire, NN9 5UG, ENGLAND

Telephone: + 44 (0) 1933 650216 Facsimile: + 44 (0) 1933 652738 Email: sales@utileengineering.com

www.utileengineering.com

13

IC182

5.

Removal of Bearings and Seals

With the rear end coverplate (3) already removed as described in 2 for blade inspection.

5.1

Using a two-leg pulley drawer the roller bearing inner race (23) can be removed from the shaft.

5.2

Should the seal sleeve (9) show signs of wear, then it can be removed by careful machining.

5.3

The bearing seal (21) and roller bearing outer race (23) can be pressed out of the coverplate for inspection.

5.4

Inspect the bearing, renew if it shows any signs of wear or pitting.

5.5

Examine the bearing seal (21) and renew if the wiping lip is worn or damaged.

With the drive end coverplate (2) already removed complete with rotor as described in 4 for cylinder renewal.

5.6

Using a two-leg pulley drawer the roller bearing inner race (22) can be removed from the shaft.

5.7

Should the seal sleeve (9) show signs of wear, then it can be removed by careful machining.

5.8

The bearing seal (21) and roller bearing outer race (22) can be pressed out of the coverplate for inspection.

5.9

Examine the bearing seal (21) and renew if the wiping lip is worn or damaged.

6.

Reassembly Procedure

This section only applies when using original bore size or replacement cylinder. Before commencing reassembly ensure that

all components are perfectly clean and oilways are clear. Lightly smear the shaft with oil to assist assembly.

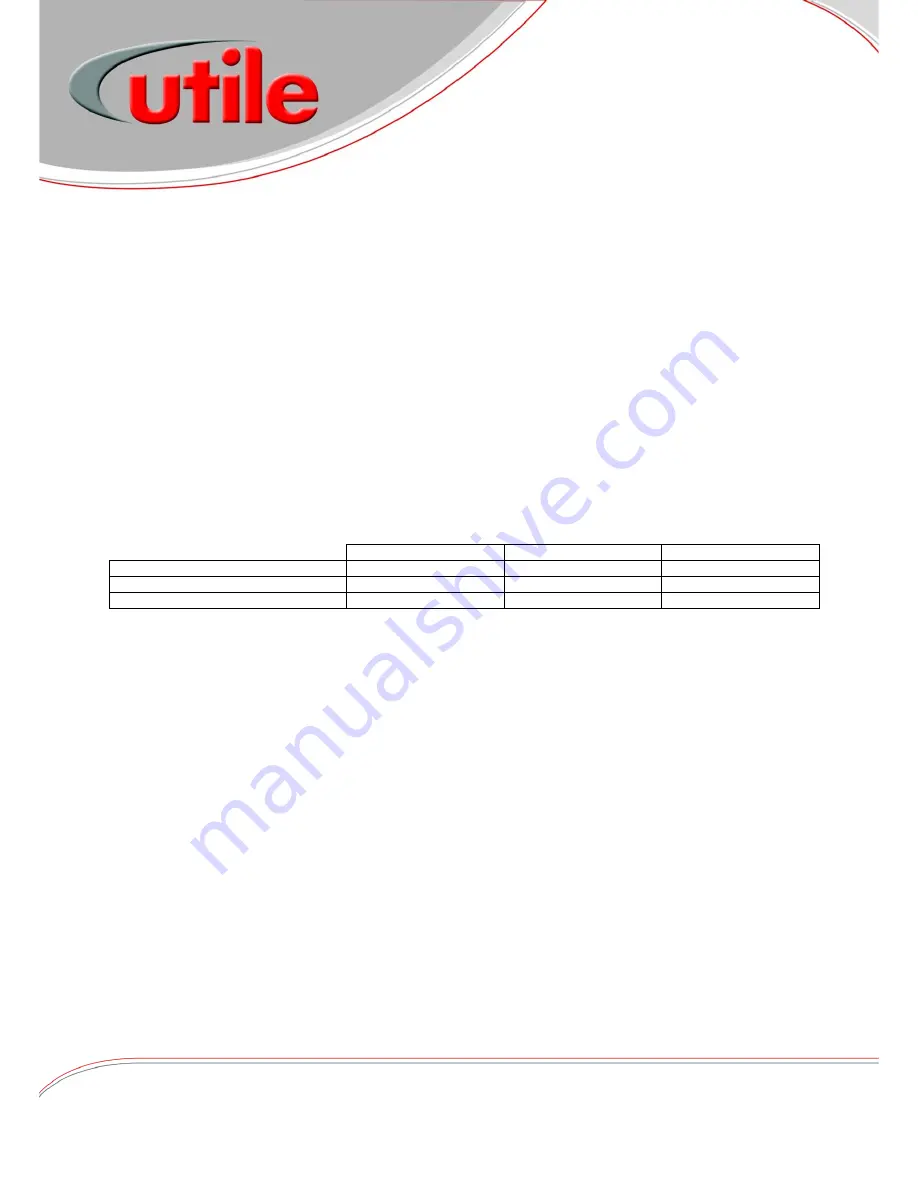

The correct clearances for these machines are: -

L95HP

L130HP

L175HP

Drive End Coverplate / Rotor

0.25mm / 0.30mm

0.25mm / 0.30mm

0.25mm / 0.30mm

Rear End Coverplate / Rotor

0.10mm / 0.13mm

0.10mm / 0.13mm

0.10mm / 0.13mm

Rotor / Cylinder

0.10mm

0.10mm

0.10mm

Reassembly should start with the preparing of the rotor and shaft assembly by the fitting of the replacement seal sleeve (if

required) and the inner races of the both roller bearings.

6.1

The seal sleeve (9) are retained on the clean shaft using LOCTITE 648 adhesive or equivalent, and should be

pushed hard against the rotor face. It is essential that the width of the seal sleeve is identical to the one it is

replacing or internal clearances may be effected causing serious machine damage.

6.2

Both roller bearing inner races can now be fitted onto the shaft ensuring the bearings and any shims are fitted to

the correct ends.

Starting at the drive end

6.3

Position the bearing seal (21) into position in the coverplate (2) ensuring that the tension spring is facing the rotor.

6.4

Press the outer race of roller bearing (22) into position in the coverplate (2).

6.5

Lay the rotor/shaft assembly on the bottom of the cylinder (1), ensure the cylinder is orientated correctly.

6.6

Ease coverplate (2) onto the rotor/shaft.

6.7

The whole bearing assembly can be locked onto the shaft with the locknut (28). Set clearance.

6.8

When fitting the mechanical seal (20), wipe over the shaft with soapy water to assist the assembly, the seal can

then be eased onto the shaft and pushed against the locknut. Replacement seal seats should be lubricated for

easier fitting in the end cap.

6.9

The end cap (3) can now be fitted with the gasket (45) and any appropriate shims.

6.10

Fit new o-rings (24) into the coverplate grooves. If coverplate gasket (45) has been replaced, it is essential that

they are the same thickness as the originals, otherwise internal clearances will be affected and could cause serious

damage. Lightly smear the gasket with oil before replacing.

6.11

Place drive coverplate assembly onto cylinder (1) via location dowel and bolt with six screws (30) and with

coverplate gaskets (45) in place.

6.12

Check rotor / cylinder clearance.

Change Bearings and Seals,

Reassembly Procedure