GAS COMPRESSORS / BOOSTERS

GAS & AIR MIXING SYSTEMS

AIR BLOWERS & VACUUM PUMPS

The Utile Engineering Co. Ltd.

Irthlingborough, Northamptonshire, NN9 5UG, ENGLAND

Telephone: + 44 (0) 1933 650216 Facsimile: + 44 (0) 1933 652738 Email: sales@utileengineering.com

www.utileengineering.com

5

IC182

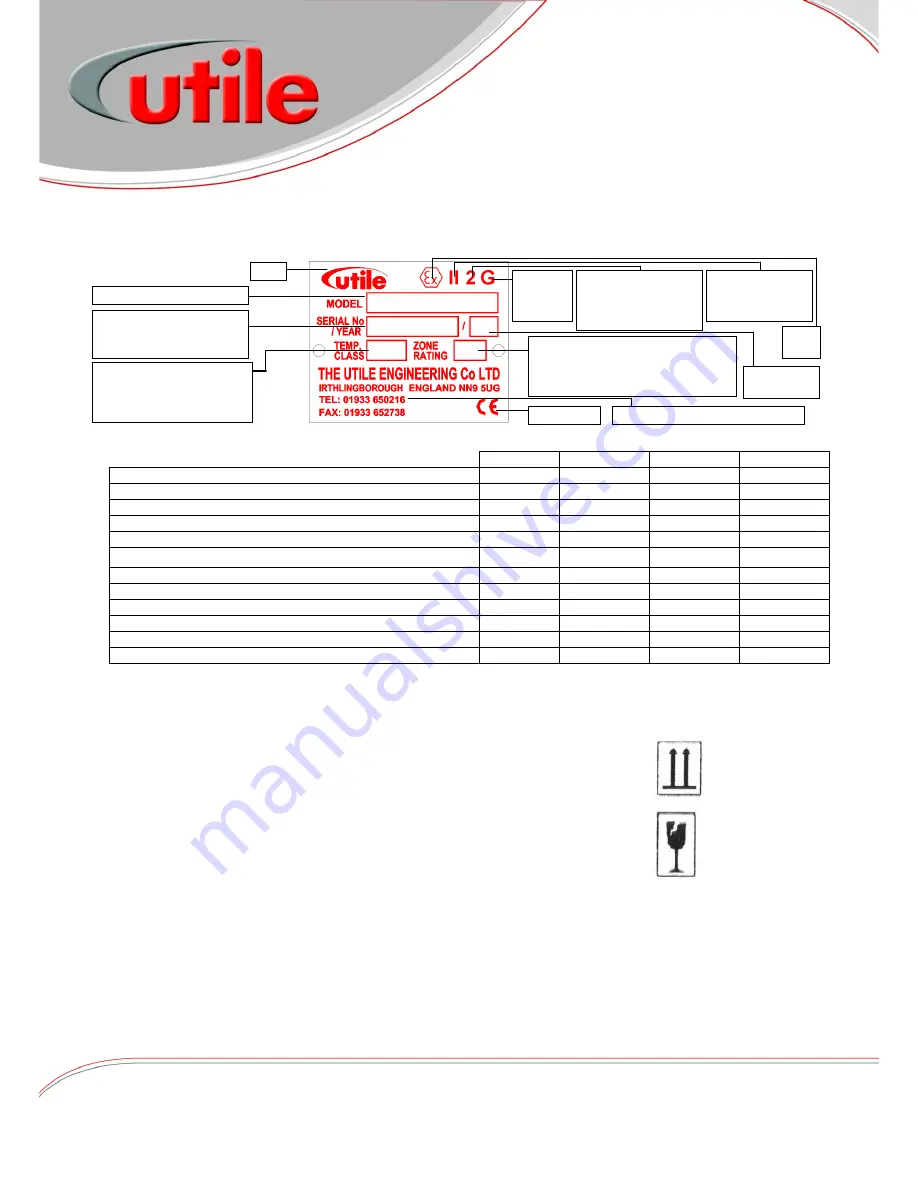

Nameplate Data

Machine Model eg L95

Machine Serial Number

(Always quote this in

correspondence)

Logo

Temperature Classification

450

C

– T1 300

C

– T2

200

C

– T3 135

C

– T4

100

C

– T5 85

C

– T6

CE Marking

Contact address & numbers

Zone Rating

0

– Very High Protection - Gas Area

1

– High Protection - Gas Area

2

– Normal Protection - Gas Area

Year of

Manufacture

Ex

Mark

Equipment Group

I

– Mines

II

– Surface Indus

Gas/Dust

G

– Gas

D - Dust

Protection Category

1

–V.High Protection

2

–High Protection

3

–Normal Protection

Technical Specification

The model, machine serial number, year of manufacture, temperature class and zone rating for the machine appear on the

machine data plate, other machine data can be found in the following table.

Units

L95HP

L130HP

L175HP

Maximum Pressure

Bar

2.00

2.00

2.00

Speed – Maximum

R.P.M.

1600

1600

1600

Speed - Minimum

R.P.M.

700

700

700

Volume at 1 Bar at Max. Speed (Air)

m

3

/hr

185

275

395

Volume at 1 Bar at Max. Speed (Bio Gas (SG=0.8))

m

3

/hr

180

265

380

Absorbed Power at 1 Bar at Max. Speed (Air)

kW

7.5

11.5

15.0

Absorbed Power at 1 bar at Max. Speed (Bio Gas)

kW

7.0

10.0

13.0

Maximum Ambient Temperature

C

40

40

40

Surface Temperature at Max. Press. at Max. Speed (Air)

C

Moment of Inertia

kg m

2

0.015

0.021

0.029

Noise Level at 1 metre

db (A)

88 - 92

88 - 92

88 - 92

Weight

kg

85

105

125

Note: Machine must not be used on any other gas than originally specified. Utile Engineering must be consulted if traces of

any other gas are introduced into the machine.

Packaging

The packaging conforms to the relevant regulations. The symbols used on the packages are

shown on the right. The machines are bolted down on a pallet and therefore should not

move during transportation and either cased or shrink wrapped for general protection. The

ancillary components are packed suitably within the case. The packaging and contents

should be received in good condition. When unpacking do not remove the inlet/outlet

protection covers.

The contents should be inspected against the advice note, notify Utile Engineering within 3

days of any items, which are damaged or are missing, followed by a written claim within

seven days of the goods being delivered.

Storage

If the machine is not required for immediate installation, the machine should be stored in a clean, dry area protected from

the weather. The intake and discharge port covers must remain in position until the machine is installed. We recommend

that the shaft be turned a few revolutions by hand to ensure the machine is running free every month until the machine is

installed.

The green protective coating on the shaft remains effective for approximately 1 year. If the machine is stored for a longer

period of time, the coat must be renewed.

Technical Specification

Packaging

Storage

Top /

This Way Up

Fragile