GAS COMPRESSORS / BOOSTERS

GAS & AIR MIXING SYSTEMS

AIR BLOWERS & VACUUM PUMPS

The Utile Engineering Co. Ltd.

Irthlingborough, Northamptonshire, NN9 5UG, ENGLAND

Telephone: + 44 (0) 1933 650216 Facsimile: + 44 (0) 1933 652738 Email: sales@utileengineering.com

www.utileengineering.com

9

IC182

Operating Notes

Daily, check the oil drip rate through the indicator. Fill the oil tank.

After the initial running in period, check the belt tension. Belt squeal denotes a loose belt that requires tightening.

Inspect the filter fitted to the inlet, regularly clean and renew the element when necessary.

Excessive discharge temperature for normal operation as indicated by the rise in temperature shown in the log book

indicates inadequate cooling, faulty lubrication or a dirty intake filter. The machine should be stopped and inspected.

Check the machine internally for wear every 10,000 running hours. (see Inspection and Service)

The blade depth should be checked after the initial 2,000 running hours and thereafter every 5,000 running hours for

wear and renew if the rubbing tips have worn to a depth of 67mm. (see Check Blade Wear).

Condensate if allowed to enter the machine can cause severe blade wear.

If adjustment of the oil drip rate is required (see lubrication).

If machine is on a standby service, run for a few minutes each week.

Stopping Procedure

Proceed as follows: -

i.

Trip out or Stop the drive motor.

Lubrication

Prime oil pipes prior to initial start and every time machine is

dismantled for service, as serious damage will occur if the

machine runs unlubricated. The lubrication system is a total

loss system, recycling of oil is not recommended

The recommended grade of oil is Shell Turbo T68 the typical

physical characteristics are shown above.

Oil feed rate per calibrated oil drip measuring device is shown

on the right. These are available from our spares department.

The feed rates can be increased/decreased pro-rata with

speed.

Oil pump adjustment

The pump is adjusted to the correct flow rate when despatched from our works. If it

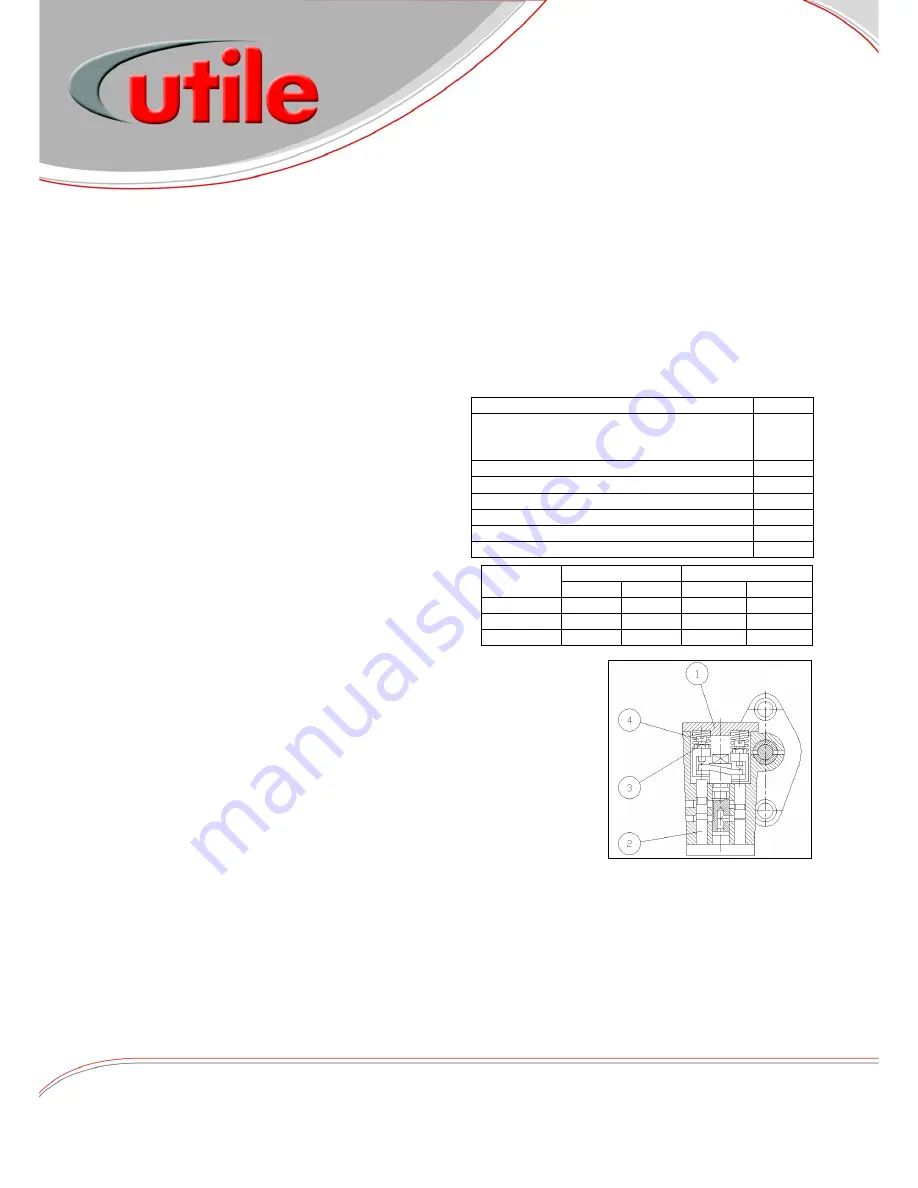

found necessary to alter the oil feed, then proceed as follows using fig. 7:

1.

Remove the cover (1) to expose two pistons (2).

2.

Slacken off the locknuts (3) and adjust the feed as required.

To increase the flow, turn the two adjusting screws (4) clockwise, or anti-clockwise to

decrease.

Lubricator Maintenance

Refill the oil reservoir regularly to ensure that the oil level is not allowed to fall to a

point where air can be drawn into the oil pump. Use only clean, new oil of the

recommended grade. At least once a year, or if the machine has been out of use for a

long period, the oil pump must be thoroughly flushed out with petrol/kerosene to clear any oil residues that may have

solidified in the control ducts. For this operation we recommend the following procedure: -

1.

Stop the machine and disconnect all the oil pipes from the oil pump.

2.

Remove oil reservoir, drain oil and wash out with petrol/kerosene. Drain again ensuring all oil residues are

removed. Replace reservoir and reconnect the oil feed pipe (oil reservoir to oil pump).

3.

Fill the reservoir with petrol/kerosene to cover oil filter element. Loosen oil feed pipe connection at oil pump end

until all air has been expelled. Re-tighten pipe.

4.

Start the machine under no load condition and run until petrol/kerosene begins to flow from oil pump discharge

points. This operation takes approximately 10 – 15 minutes and providing the machine is run under no load

conditions, no damage will occur.

5.

Stop machine, drain oil reservoir and fill with recommended grade of oil. Ensure all oil pipes are primed. Reconnect

oil delivery pipes (oil pump to machine) and start up.

Operating Notes

Stopping Procedure

Lubrication

Fig. 7

Fig. 7

Shell Turbo Oil

T68

Kinematic Viscosity

@ 40

C cSt

100

C cSt (IP71)

68

8.8

Viscosity Index

(IP226)

102

Pour Point

C (IP15)

-6

Density

@ 15

C kg/l (IP160)

0.876

Flash Point

(PMCC)

C (IP34)

210

Demulsibilty Number

max. (IP19)

210

Neutralisation Number

mg KOH/g (IP139)

0.15

Model

Speed 900 Rpm

Speed 1400 Rpm

Air

Biogas

Air

Biogas

L95HP

7.25

9.00

11.25

14.00

L130HP

9.00

11.25

14.00

17.50

L175HP

10.75

13.50

16.75

20.75

Oil feed rate per calibrated oil drip indicator using oil pump timing drive speed ratio 1:1