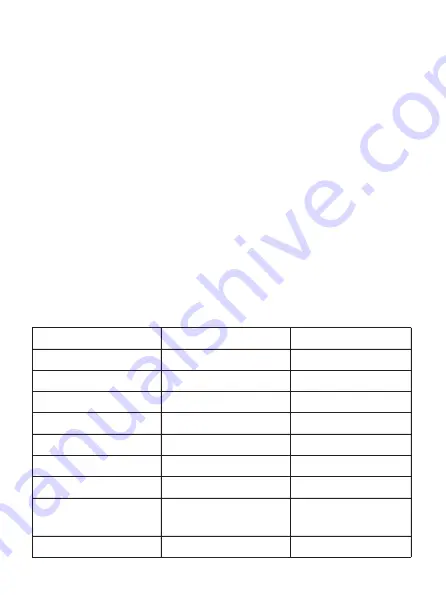

8. Application

Area

Item

42m²×3m

Specifications

Volume 126m³

Comment

Disinfectant

8% hydrogen peroxide

Dose

5ml/m³

Atomizing value setting

16ml/min

System default value

Total dose of disinfectant

630ml

126m³ x 5ml/m³ =630

Total spraying time

39min

630/16=39

Sealing time

60min

Ventilation with all door

and window opening

120min

Total disinfect time

249min

39+60+120=249

When forced ventilation is

used, the duration of residue

removal can be reduced

■

Disinfectant use

The dry fog hydrogen peroxide disinfector is used with 6% ~ 9% hydrogen peroxide disinfectant

Note

: This equipment can also be used with other sporicides such as peracetic acid. The effectiveness

of sterilization is related to the use of disinfectants. Please choose a suitable disinfectant.

Note

: If the hydrogen peroxide solution used is less than 6% (but no lower than 3%), additional dry

fog spraying will be necessary to achieve the desired sterilization effect. How much additional time is

directly proportional to the reduced solution percentage (ie, if 3% solution is used, the equipment

must be set to spray twice the needed amount, which also means twice the amount of time compared

to 6% solution.). Dwell time and residue removal duration is not affected

■

User safety

The user use 3M8514 welding protection mask (or equal grade protection masks) when using

hydrogen peroxide to disinfect

B: Second, keep room sealed and closed for 1-1.5 hours

After the running time displayed on the parameter setting interface ends, the equipment

automatically stops running and the spraying ends. After spraying, the entire sterilization area is

filled with disinfectant, wait for 1.5 hours before opening doors and windows

C: Third, removal of residues 1-2 hours (hydrogen peroxide concentration is less than 1ppm)

Turn on the air-conditioning exhaust system to remove the disinfectant in the space, and personnel

can enter the sterilization area after the air-conditioning system has been running for more than 2

hours.