E

N

G

L

IS

H

43

m

PHOTOCELLS - INSTRUCTIONS

• The control unit powers the photocells at a nominal voltage of

24 Vdc, with an electronic fuse that breaks the current in the

case of an overload.

• If the transmitter power supply is connected to terminals

E3 (+)

and

E2 (-)

, the control unit can perform the photocell

operation test prior to starting gate opening.

• The photocells on the interior side should be installed so as to

completely cover the gate opening area.

• If several pairs of photocells are installed on the same side of

the gate, the receiver N.C. outputs should be connected in

series.

• The photocells are not powered when the control unit is in

ENERGY SAVING mode.

4.3 - CONNECTING PHOTOCELLS

The control unit considers two kinds of photocells, depending on

the terminal to which they are connected:

•

Photocell 1:

that is to say, photocells installed on the gate

inner side, which are active both during the opening and the

closing phase. When photocells 1 operate, the control unit

stops the gate; as soon as the photocell beam is free, the

control unit will open the gate completely.

•

Photocell 2:

that is to say, photocells installed on the

external gate side and which are active during the closing

phase only. When photocells 2 operate, the control unit

opens the gate immediately, without waiting for release.

• Connect power supply cables of photocells transmitter

between terminals

E3 (+)

and

E2 (-)

of the control unit.

• Connect power supply cables of photocells receiver

between terminals

E1 (+)

and

E2 (-)

of the control unit.

• Connect receiver output of photocells 1 between terminals

J5 (PHOTO1)

and

J9 (COM)

of the control unit and receiver

output of photocells 2 between terminals

J6 (PHOTO2)

and

J9 (COM)

of the control unit.

Use outputs having normally closed contact.

m

SAFETY RIBBONS - INSTRUCTIONS

• If several edges, with normally closed contacts, are used, the

outputs should be connected in series.

• If several conductive rubber edges are used, the outputs should

be connected in cascade, and only the final edge should be

terminated on the nominal resistance.

• Active edges connected to the accessory power supply are

inactive when the control unit switches to ENERGY SAVING

mode.

• To meet the requirements of EN12978, it is necessary to install

conductive rubber sensitive edges; contact normally closed

sensitive edges should have a control unit that constantly

verifies their correct operation. If control units with the option

to conduct testing by interrupting the power are used, connect

the control unit power cables between terminals

E3 (+)

and

E2 (-)

on the PD13.

Otherwise, connect them between terminals

E1 (+)

and

E2 (-)

.

Testing the edges should be activated by means of the

Co.tE

menu.

4.4 - CONNECTING SAFETY RIBBONS

The control unit considers two kinds of safety ribbons,

depending on the terminal to which they are connected:

•

Type 1 (fixed):

they are mounted on walls or on other fixed

obstacles that are approached by the gate doors during the

opening phase. When type 1 safety ribbons operate during

the gate opening phase, the control unit will close the doors

for 3 seconds, then it stands still; when type 1 safety ribbons

operate during the gate closing phase, the control unit will

stand still immediately. The direction of the gate at next

command of START or PEDESTRIAN START depends upon the

parameter STOP (it inverts or continues the motion).

If the input STOP is disabled, the command makes the motion

continue in the same direction.

•

Type 2 (mobile):

they are mounted to the door ends.

When type 2 safety ribbons operate during the gate opening

phase, the control unit will stand still immediately; when

type 2 safety ribbons operate during the gate closing, the

control unit will open the doors for 3 seconds, then it will

stand still. The direction of the gate at next command of

START or PEDESTRIAN START depends upon the parameter

STOP (it inverts or continues the motion). If the input STOP

is disabled, the command makes the motion continue in the

same direction.

Both the input can manage the classic safety edge with n.c.

contact and the conductive rubber safety edge with 8,2 kohm

nominal resistance.

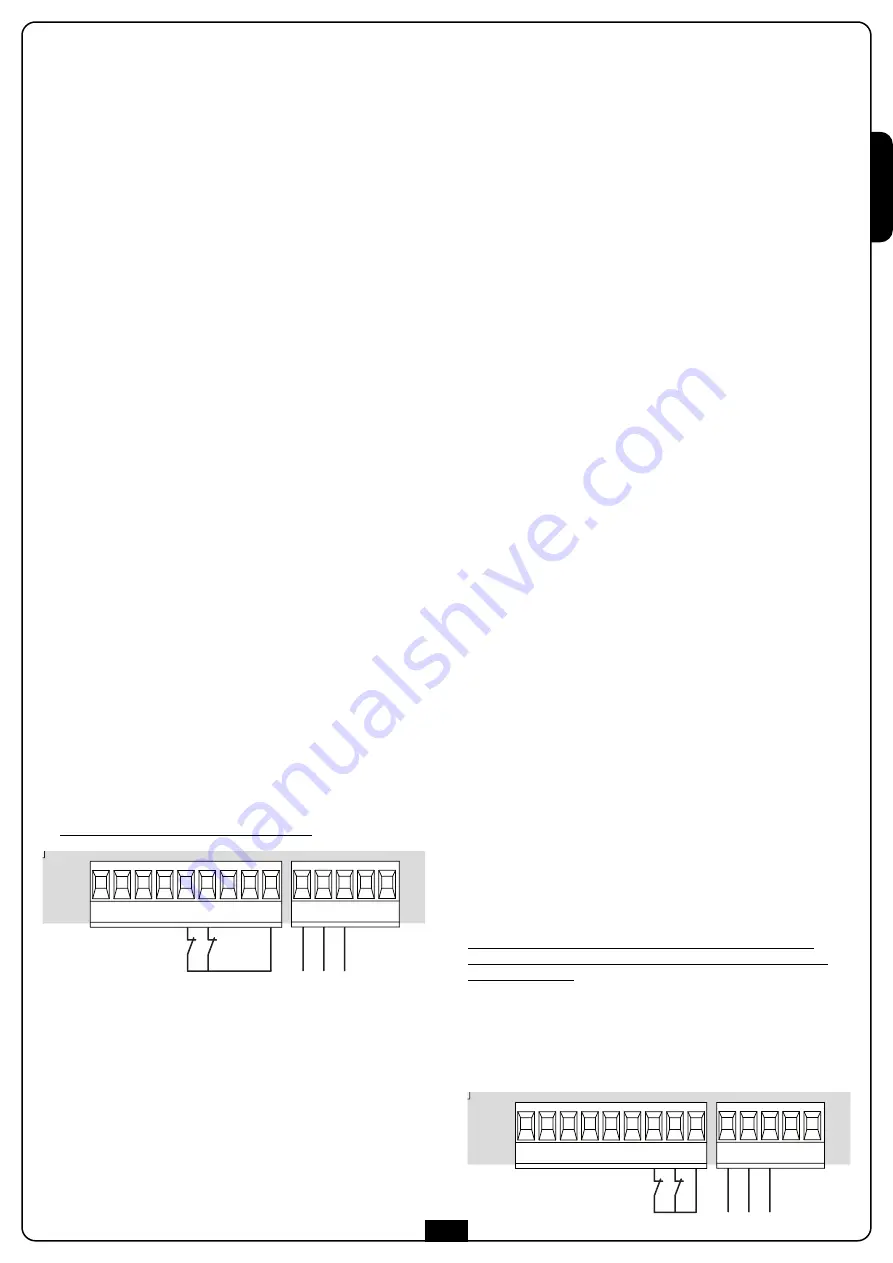

Connect type 1 safety ribbons cables between terminals

J7 (EDGE1)

and

J9 (COM)

of the control unit.

Connect type 2 safety ribbons cables between terminals

J8 (EDGE2)

and

J9 (COM)

of the control unit.

J9

J8

J7

J6

J5

J4

J3

J2

J1

B1

B2

E5

E3

E4

E2

E1

J9

J8

J7

J6

J5

J4

J3

J2

J1

B1

B2

E5

E3

E4

E2

E1

Summary of Contents for ALFARISS

Page 2: ......

Page 15: ...ITALIANO 13...

Page 36: ...ITALIANO 34...

Page 49: ...ENGLISH 47...

Page 70: ...ENGLISH 68...

Page 83: ...FRAN AIS 81...

Page 104: ...FRAN AIS 102...

Page 117: ...ESPA OL 115...

Page 138: ...ESPA OL 136...

Page 139: ......