ENGLISH

- 6 -

WALL INSTALLATION (Fig. 1)

For the system to function correctly, it is essential that the flatness

and linearity of the surfaces intended for installation be checked,

then FIX THE PROJECTOR ALONG THE SAME GEOMETRICAL AXIS

AND AT THE SAME HEIGHT ABOVE THE GROUND, IN FRONT OF

THE RECEIVER.

The SHIELD-180 photocells have a horizontal scope of 180° and a

vertical scope of 30°, they can also be applied on uneven surfaces

where the correct alignment between TX and RX is not possible.

For correct installation, follow the instructions below very

carefully:

• Decide where the photocells are to be installed, taking into

account the need for the photocells to be fixed on a flat, linear

surface.

m

PLEASE NOTE: position the photocells so as to avoid

that the receiver RX facing into the sun.

• Decide where to place the channels for the power supply

cables.

• Open the photocell casing and use the base

A

to mark out the

positions of the fixing holes.

• Attach the base

A

• Remove the cable gland

D

• Carry out the electrical connections by passing the cable

through the cable gland

E

.

• Place the cable gland

D

ELECTRICAL CONNECTIONS

m

WARNING: The installation of the unit, safety devices

and accessories must be carried out when the power supply

is disconnected

The new range of devices is equipped with a synchronism circuit

allowing the installation of two pairs, even very close together,

without them interfering with one another.

m

WARNING: the supply of TX and RX must be in phase

(e.g. TX earth with RX earth and 24 V AC TX with 24 V AC

RX).

Synchronised operation - connect as Fig. 4

Supply both pairs of photocells with AC current, inverting the

polarity between the first and second pairs.

Non-synchronised operation - connect as Fig. 5

Supply by direct or alternating current the two pairs of photocells

and install the two pairs in the reverse order with respect to one

another.

JUMPER (Fig. 3)

JUMPER J1 (RX)

Position A - relay output with normally closed contact (DEFAULT)

Position B - relay output with normally open contact

ADJUSTMENT

Having completed the installation, check that the system is

operating correctly:

1.

Ensure there are no obstacles between the transmitter and the

receiver.

2.

Power-up the system:

- The receiver LED is off: The photocell is not centred, slowly

swing the movable part until the receiver LED comes on

- The receiver LED is on: the photocell is centred, move on to

part 3.

m

WARNING: If the receiver LED flashes, the power

supply of TX and RX is out of phase. Check the electrical

connections.

3.

Fix the mobile part of the photocell by tightening the screw

M

4.

Place the cover

B

over the photocell and ensure it is operating

correctly without removing the adhesive attenuation filter

C

(the filter simulates adverse weather conditions such as rain,

fog etc.)

5.

Then remove the attenuation filter.

6.

Break the infrared beam a number of times: the receiver LED

must switch itself off and the relay must switch.

7.

Insert the aluminium cover

F

and tighten the 4 screws

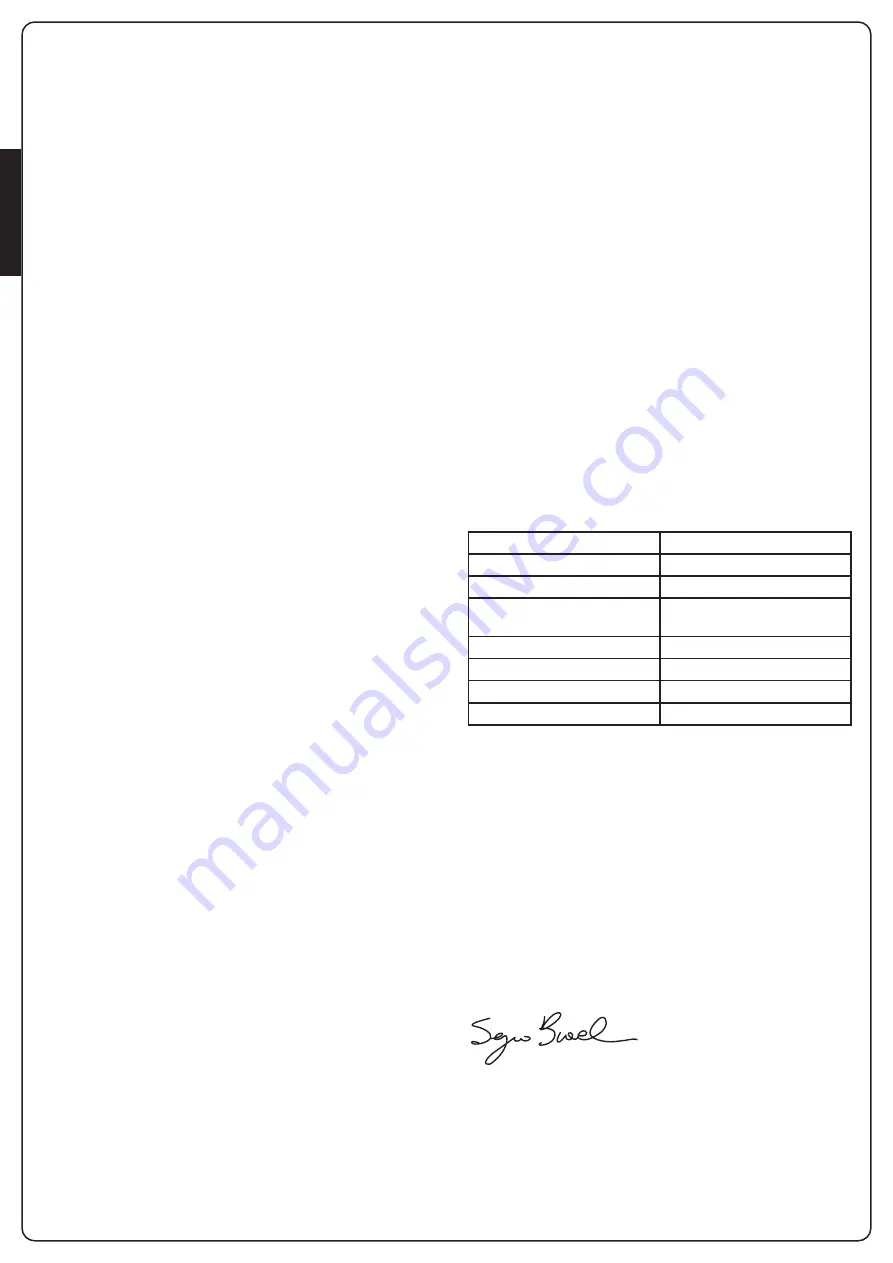

TECHNICAL SPECIFICATIONS

Optical range

20 m

Dimensions

74x141x55 mm

Power supply (VIN - GND)

12÷24 Vac / 12÷36 Vdc

Signal

modulated infrared 2 KHz

l

= 940 nm

Relay contact

1A max 30 VDC

Absorption (VIN = 24Vdc)

TX 15 mA RX 20 mA

Operating temperature

-20° + 60° C

Protection degree

IP55

EU DECLARATION OF CONFORMITY

The manufacturer V2 S.p.A., headquarters in Corso Principi di

Piemonte 65, 12035, Racconigi (CN), Italy

Under its sole responsibility hereby declares that the products:

SHIELD-180

comply with the following directives:

2014/30/EU, ROHS-3 2015/863/EU

Racconigi, 01/06/2019

Legal representative, V2 S.p.A.

Sergio Biancheri