20

Electro-pneumatic positioner TZIDC-220

42/18-82 EN

3.2 Pneumatic connection

3.2.1 Safety instructions

3.2.2 Making the pneumatic connections

All pneumatic piping connections are located on the right-hand side of the positioner.

Threaded bores G 1/4 or 1/4-18 NPT, respectively, are provided. The positioner is

labeled according to the type of thread. The corresponding screwed pipe connections

have to be supplied by the customer. We recommend pipes with the dimension 6 x 1 mm

for the pneumatic piping.

The amount of supply pressure has to be matched to the working pressure necessary for

the actuation. The positioner's operating range is between 1.4 and 6 bar.

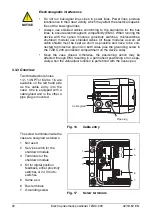

!

WARNING

•

Observe the accident prevention rules of the Employers Liability

Insurance Association.

•

Observe the safety instructions for the pneumatic actuator used. The

actuator's high actuating power may cause injuries!

!

NOTICE

•

Take suitable precautions to ensure that even in case of malfunctions

the positioner’s max. admissible operating pressure of 6 bar (90 psi) is

not exceeded. Otherwise, the positioner and/or the actuator may be

damaged.

•

The positioner must be supplied with instrument air exempt from oil,

water and dust according to DIN/ISO 8573-1, Class 3

- Purity: max. particle size 5 µm, max. particle density 5 mg/m

3

- Oil content: max. concentration 1 mg/m

3

- Pressure dew point: maximum value 10 K below operating temp.

3

Before connecting the air pipes blow them out to remove dust,

splinters and other particles.

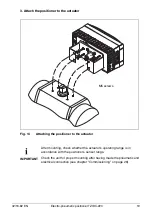

Pneumatic outputs

Air supply

Fig. 15

Pneumatic connections

Summary of Contents for D400

Page 40: ...40 Electro pneumatic positioner TZIDC 220 42 18 82 EN 5 Certificates...

Page 41: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 41...

Page 42: ...42 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 43: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 43...

Page 44: ...44 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 45: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 45...

Page 46: ...46 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 47: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 47...

Page 48: ...48 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 49: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 49...

Page 50: ...50 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 51: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 51...

Page 52: ...52 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 53: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 53...

Page 54: ...54 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 55: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 55...

Page 56: ...56 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 64: ...64 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 65: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 65...

Page 66: ...66 Electro pneumatic positioner TZIDC 220 42 18 82 EN...

Page 67: ...42 18 82 EN Electro pneumatic positioner TZIDC 220 67...