Mounting

Procedure:

1. Mounting the adapter on the positioner

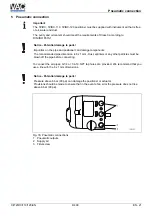

Fig. 10

• Determine the mounting position (parallel to actuator or at 90° angle)

• Calculate the rotational direction of the actuator (right or left)

• Move the rotary actuator into home position

• Based on the mounting position as well as the home position and rotational direction of the

actuator, determine in which position the feedback shaft (1) for the positioner must be pre-

adjusted and in which position the adapter (2) must be placed to enable the positioner to

travel within the proper range (the arrow on the rear of the device must travel within the

admissible range, see Fig. 1)

• Pre-adjust feedback shaft

• Place the adapter in the proper position on the feedback shaft and fasten with set screws (3).

One of the set screws must be locked in place on the flat side of the feedback shaft

CI/TZIDC/110/120-EN

D400

EN - 15