Page 9 of 13

sales@vacgen.com

www.vacgen.com

+44 (0) 1424 836 333

5.3 Installation

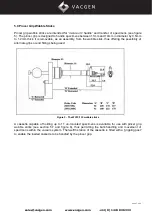

To obtain the full angular movement of the wobble stick it is necessary that the bore of the tabulation

to which it is attached should, ideally, be 41mm (not less than 38.5mm) in diameter.

The rotational orientation chosen is normally determined by the most convenient parking position and

by the required orientation of the specimen.

5.4 Operation

The pincer grip wobble stick has been designed for use with a cassette, and with certain of the

standard VACGEN accessories, principally the model HST non-inductive resistive

heater and model

EBH electron beam heater. Both of these heaters can also be used for combination heating and

cooling and both are suitable for 'in-vacuum' attachment and removal of specimens using the pincer

grip device. A typical mode of operation would be as follows:

1) The cassette with the desired number of specimens would be placed on a transporter either in an

entry lock, or preparation chamber, which would then be evacuated.

2) The transporter would then move the cassette to the next stage where it would either be

transferred to the next transporter (if initially placed in an entry lock) or onto a parking position (in the

main analysis chamber), by the wobble stick.

3) Assuming the cassette is parked in the main chamber (the parking position must of course be such

that it is accessible to the pincer grip wobble stick), the nose of the pincer grip can be used to index

the cassette to bring the required specimen into alignment with the pincer grip jaws. The stub on

which the cassette is mounted has a 12 position capstan which engages with a spring-loaded detent

incorporated in the cassette. The cassette also has 6 slots on the periphery into which the nose of the

pincer grip jaws can be engaged when it is desired to index the cassette.

4) Open the jaws of the pincer grip. Engage and grip the specimen by releasing the plunger button.

Carefully retract the wobble stick removing the specimen from the cassette.

5) Align the face of the heater platten by rotation of the primary axis of the manipulator rotary drive so

that it is parallel with the rear face of the specimen. Insert the specimen under the spring clips (which

should previously have been adjusted to suit the thickness of the specimen being used), and gently

slide the specimen further under the spring clips. Now release the grip and use the end of the (closed)

jaws to position the specimen in the centre of the heater plate. If the specimen should be pushed too

far, it can be pulled back by using the claw on the underside of the lower jaw. It will be found easier to

engage the claw if the specimen holder is rotated through an angle of about 5

o

- 10

o

to raise the level

of the far side of the specimen above that of the near-side.

6) To remove the specimen, the claw is used to slide the specimen until about one third to one half of

the diameter is projecting over the side of the heater. Take care not to slide the specimen too far out

of the clips otherwise it may be dropped. Now align the face of the specimen parallel to the jaws, grip

the specimen, remove it from the heater and replace it in the cassette.

After heating metallic specimens to high temperatures, increased force may be required to slide the

specimen initially; this is probably due to the occurrence of localized cold welding. Once the specimen

has been moved, further movements will not be difficult to achieve.