182

• VACON®

apfiff09 marine

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.7 DC current and magnetization handling

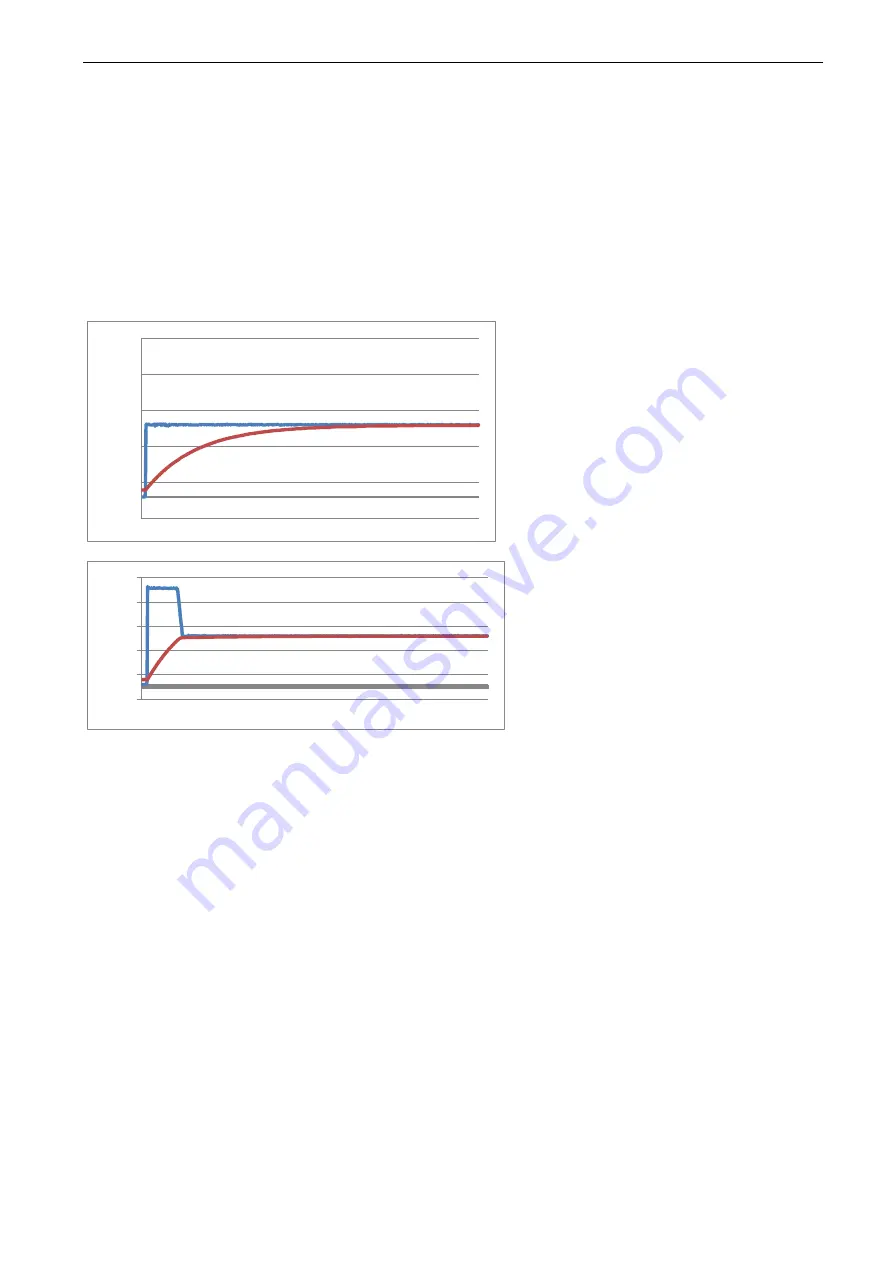

The DC brake can be used to hold the motor in place (nominal torque at nominal slip). It can be also

used to keep the motor warm in places with high humidity and to speed up the generation of rotor

flux. Rotor flux is needed in the induction motor to generate torque. The current that is needed to

make the nominal flux is defined by the magnetization current parameter but, depending on motor

size, nominal flux takes a different time to produce after start command.

Giving a higher current on start to the motor will decrease the time when the motor is able to

generate nominal torque.

Blue: Motor Current. Red: Rotor Flux.

7.7.1 Open loop settings

P2.7.1.1

DC-braking current

ID627

“DC

-

Brake Current”

Defines the current injected into the motor during DC-braking. On start, this parameter is

used together with DC Brake time to decrease the time when motor is able to produce

nominal torque. When DC brake current is applied to the motor the output frequency is

zero.

P2.7.1.2

DC-braking time at start

ID507

“Start

DC-

BrakeTm”

DC-brake is activated when the start command is given. This parameter defines for how

long the DC current is given to the motor before acceleration starts. DC brake current at

start is used in order to magnetize the motor before running, which will improve the

torque performance at start. Needed time depends on motor size, value varying between

100 ms to 3 second. The bigger the motor the more time is needed.

The default setting 0.00 s means that 200 ms is spent to magnetize motor. This 200 ms

can be set to zero with

parameter “MakeFluxTime”

.

Activating flying start will disable the DC brake functions at start.

-300

200

700

1200

1700

2200

0.0

1

0.4

0.7

9

1.1

8

1.5

7

1.9

6

2.3

5

2.7

4

3.1

3

3.5

2

3.9

1

4.3

4.6

9

5.0

8

5.4

7

5.8

6

6.2

5

6.6

4

-300

200

700

1200

1700

2200

0.0

1

0.4

0.7

9

1.1

8

1.5

7

1.9

6

2.3

5

2.7

4

3.1

3

3.5

2

3.9

1

4.3

4.6

9

5.0

8

5.4

7

5.8

6

6.2

5

6.6

4

Summary of Contents for apfiff09 marine

Page 1: ...vacon nx ac drives apfiff09 marine application manual ...

Page 2: ......

Page 310: ......