page 43 of 56

Assembling the pump heads

➨

Place the pump in a way that the pump head to be assembled is at the

top. Support the pump appropriately.

➨

Bring the diaphragm (F) into a position in which it is in contact with the

housing (J) and centered with respect to the bore.

➨

Place the head cover (D) over the diaphragm. Check for its correct

orientation by aligning it beforehand with the housing cover which has

to be put over it later on.

+

Pay attention that the diaphragm (F) stays positioned centrally so that

it will become clamped uniformly between housing (J) and head cover

(D).

➨

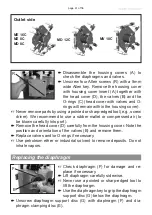

Place the valves (B) and the O-rings (C) at

their respective positions on the head cover

(D).

+

Make sure that the valves are correctly

seated. See figure for the correct position of

the valves: Valves at the outlet with round

centered opening (S) under valve; valves at

the inlet with kidney-shaped opening (T) be-

side valve.

➨

Place the housing cover (A) with housing

cover insert onto the head cover.

S

T

➨

Loosely screw in the Allen head screws (R)

of the housing cover in a start pattern with a

5 mm wide Allen key, then tighten.

+

Recommended torque: 8.9 ft

.

lb

f

(12 Nm).

R

Summary of Contents for ME 16C

Page 54: ...page 54 of 56...

Page 55: ...page 55 of 56...