page 97 of 152

Fault

Possible cause

Remedy

❑

No digital pressure

reading.

➨

Pressure transducer

defective?

✔

Contact local distributor.

❑

Digital pressure

reading is flashing,

one blip*.

➨

Overpressure at the

pressure transducer,

pressure > 795 Torr

(1060 mbar)?

✔

Release pressure imme-

diately (risk of bursting).

❑

Warning triangle

and black valve

symbol are flash

-

ing, two blips*.

➨

External venting valve

removed or defective?

✔

Connect valve or replace

with a new one or recon-

figure without valve.

❑

Warning triangle

and valve symbol

are flashing, three

blips*.

➨

NT VARIO pump and

in-line valve connect-

ed?

✔

Disconnect in-line valve;

switch controller off/on to

reconfigure.

❑

Warning triangle

and coolant valve

symbol are flash

-

ing, four blips*.

➨

Coolant valve removed

or defective?

✔

Check connection cable

of the valve; or use new

valve or reconfigure with

-

out valve.

❑

Warning triangle

and pump symbol

are flashing, six

blips*.

➨

NT VARIO pump and

VMS** (Vacuum Man-

agement System) con-

nected?

✔

Remove VMS. Restart

controller.

➨

Fault at the NT VARIO /

pump?

✔

Check pump, restart con-

troller.

❑

Clock symbol is

flashing.

➨

Preselected process

time is over?

✔

Confirm by pressing

START/STOP key.

❑

Venting valve does

not respond, valve

symbol is dis-

played.

➨

Venting valve contami-

nated?

✔

Clean valve.

❑

”Vac control” func-

tion: Control stops,

”arrow up” is flash

-

ing.

➨

Preset maximum pres-

sure exceeded?

✔

Confirm by pressing

START/STOP key.

Change maximum pres-

sure value if necessary.

❑

”Pump down” func-

tion: Control stops,

”arrow down” is

flashing.

➨

Pressure below preset

minimum pressure?

✔

Confirm by pressing

START/STOP key.

Change minimum pres-

sure value if necessary.

❑

Controller does

not respond when

pressing keys (ex-

cept ON/OFF).

PC symbol is dis-

played.

➨

Controller in remote

mode?

✔

Control CVC 3000 via in-

terface or switch off re-

mote mode.

Summary of Contents for MV 10C NT VARIO o.C.

Page 34: ...page 34 of 152 1 8 2 9 18 PC 3012 NT VARIO EK Peltronic 12 11 16 8 17 3 4...

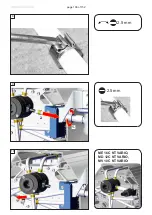

Page 104: ...page 104 of 152 2 3 size 1 2x 4...

Page 105: ...page 105 of 152 6 5 7 4 4x...

Page 106: ...page 106 of 152 9 8 1 2 2 5 mm 2 5 mm 10 ME 16C NT VARIO MD 12C NT VARIO MV 10C NT VARIO...

Page 108: ...page 108 of 152 12 Emission condenser Peltronic 4 4x 11A 13 4 2x...

Page 109: ...page 109 of 152 15 14 4 4x Don t loosen this screw 15A 16...

Page 110: ...page 110 of 152 16 17 5 2x 15A 1 2 3 1 4 1 4 3 2x 5...

Page 111: ...page 111 of 152 19 20 18 5 2x...

Page 113: ...page 113 of 152 21 2 5 mm Replacing the diaphragms 22 23 696867 696839 Clean 5 8x...

Page 114: ...page 114 of 152 24 25 26 1 2...

Page 115: ...page 115 of 152 27 3 28 29 Pay attention to number of washers...

Page 118: ...page 118 of 152 36 37 38 Clean...

Page 119: ...page 119 of 152 39 40 41 IN IN EX EX 696867 696839 4x...

Page 120: ...page 120 of 152 42 43 44 IN EX T20 4x 2 2 ft lbf 3 Nm...

Page 121: ...page 121 of 152 45 46 47 Maintain all pump heads in the same way...

Page 125: ...page 125 of 152 2 size 2 2x 3 4A Version A valve 24 4 mm...

Page 126: ...page 126 of 152 5A 696839 24 4 mm 26 mm 4B 5B 696839 37 mm 40 mm Version B valve 37 mm...

Page 127: ...page 127 of 152 6 7 size 2 2x 7A ME 16C NT VARIO MD 12C NT VARIO MV 10C NT VARIO size 2 2x...

Page 129: ...page 129 of 152 49 Assembling the pump housing 50 51 5 2x 8 9 ft lbf 12 Nm...

Page 130: ...page 130 of 152 52 53 54 5 2x 8 9 ft lbf 12 Nm...

Page 131: ...page 131 of 152 55 55A 1 2 3 3 2x 55A 56...

Page 132: ...page 132 of 152 56 4 4x 3 7 ft lbf 5 Nm 58 4 4x 3 7 ft lbf 5 Nm 57 4 2x 3 7 ft lbf 5 Nm...

Page 133: ...page 133 of 152 59 60 61...

Page 135: ...page 135 of 152 62 63 4 4x 3 7 ft lbf 5 Nm 64...

Page 136: ...page 136 of 152 65 66 67 size 1 2x...

Page 137: ...page 137 of 152 68 69...

Page 140: ...page 140 of 152 4 638821 638821 5 6...

Page 141: ...page 141 of 152 7 T20 4x size 1 4x 8...

Page 149: ...page 149 of 152...

Page 150: ...page 150 of 152...

Page 151: ...page 151 of 152...