24

VADA FLOW BOSS

HORIZONTAL MULTISTAGE PUMP

VFB-HM110

INSTALLATION MANUAL

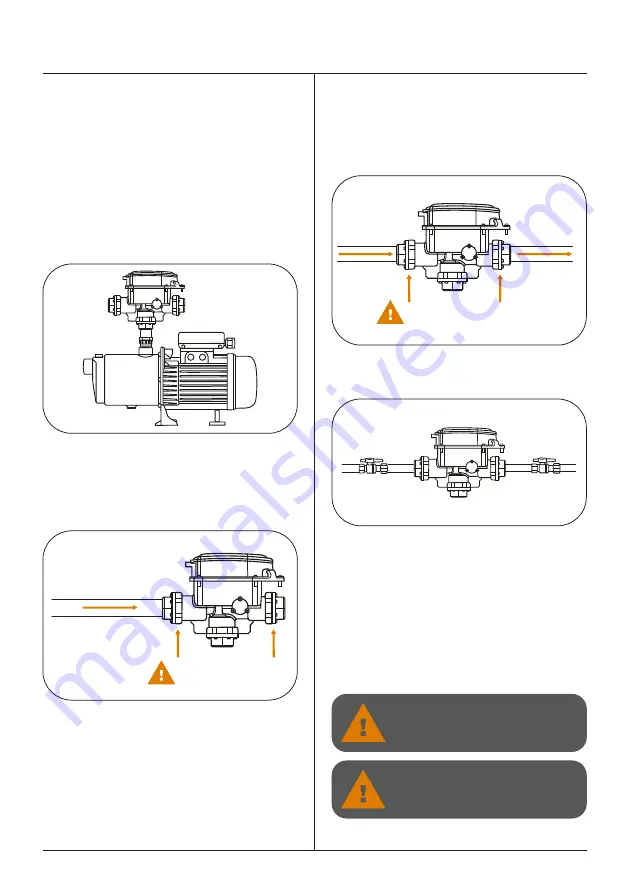

8. Connect the 25mm female end of the

switching unit to the household plumbing

supply. This is marked ‘OUTLET’ on the

unit with an arrow pointing out of the unit

(indicating water flow direction).

9. For easy maintenance install an isolation

valve on either side of the VFB-DSU.

Note:

Vada strongly recommends installing

the float switch (supplied), in the tank on

site. Installing a float switch prevents air from

re-entering the suction line and damaging your

Vada product. Installing a float switch also

reduces build up from tank debris entering

the pump.

For full installation instructions, refer to the

Vada VFB-DSU manual.

Note:

If you cannot screw the switching

unit on top of the barrel union due to space

limitations, you can unscrew the barrel

union nut and release the nipple from the

union. Rethread the nipple into the switching

unit making sure the union nut remains on

the nipple. Re-join the union to complete

connection.

6. Connect the VFB-DSU to the discharge

port on the pump.

7. Connect the 25mm female end of the

switching unit to the incoming mains

water supply. This is marked ‘MAINS’ with

an arrow pointing out of the VFB-DSU

(indicating water flow direction).

Note:

Brace this fitting to prevent movement

while connecting to the mains supply.

To toilet,

garden,

laundry

Mains supply

Grip and brace the connection

while fitting pipework

Brace this fitting to prevent

movement while connecting

to the mains supply.

Movement of this fitting

could disturb internal seals,

causing leakage.

INSTALLATION

Grip and brace the connection

while fitting pipework

Mains supply

Isolation

valve

Isolation

valve

Summary of Contents for VFB-HM110

Page 1: ...HORIZONTAL MULTISTAGE PUMP INSTALLATION MANUAL VFB HM110...

Page 53: ...53...

Page 56: ......