Safety rules

10

01.05.2015 1

1.4

Other rules governing safety

Figure 1.4

!

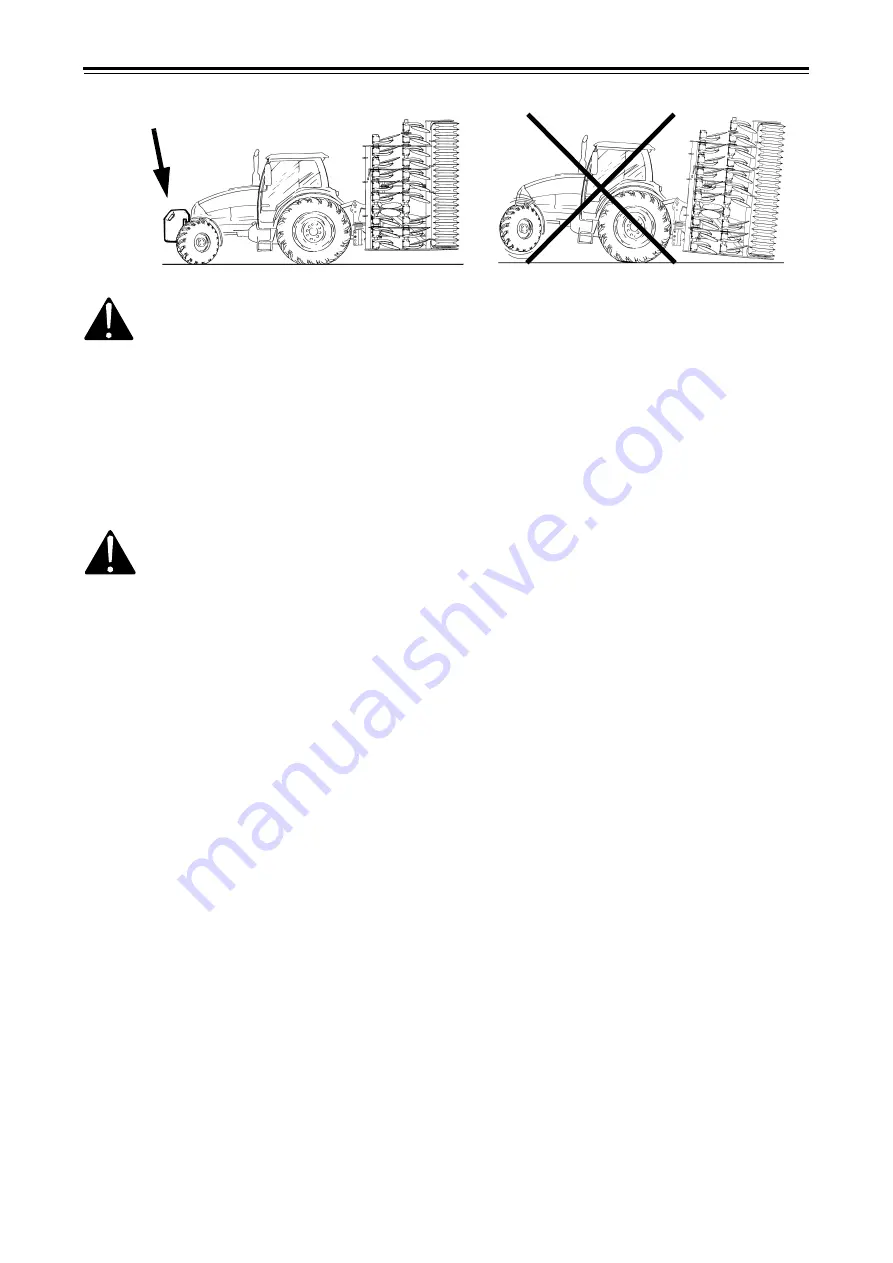

Because the implement is heavy, front weights should be fitted to the tractor in most instances.

Always ensure that the front axle of the tractor is sufficiently loaded to allow it to be driven

safely.

!

Check that the tractor's tyre set up has been adapted to cope with the weight of the implement

and that the tyres are inflated to the correct pressure. Note that the load exerted on the rear axle

of the tractor is high, particularly when transporting by road. Therefore check to ensure that the

maximum permitted axle load is not exceeded.

!

Pay close attention to the width and turning circle of the implement during transport. Always

adhere to national traffic regulations. The tractor driver has sole responsibility for ensuring that

the equipment is conveyed on the road in a safe manner.

!

Keep in mind that the implement is heavy and, as a result, the braking distance is longer.

!

Pay close attention to the height of the implement when transporting it on the road, particularly

in the case of the CRX 625. Be particularly aware when passing air ducts, over road bridges,

in tunnels, etc. In certain countries, the maximum transport height is 4 m.

!

Set the lifting height of the hydraulic arms so that there is sufficient ground clearance when

transporting the implement by road.

!

Use the lights on the implement in accordance with local traffic regulations. Note that the po-

sition of the lights will change when the implement is raised and lowered using the hydraulic

arms. Clean the lights and check that they work prior to going out on the road.

!

Before transporting the implement by road, check that the wing section mechanical locks are

fully engaged, see

“2.6 Switching to transport mode” on page 23

.

!

Prior to transport on public roads, remove any soil that may fall off from both the tractor and

implement.

!

Do not go under the implement if it is only secured in position by the tractor's three point lift!

Section

“4.1 Securing the implement for service” on page 32

shows how the implement should

be chocked up.

!

When carrying out any servicing or repair work on the hydraulic system, the side sections must

always be retracted and the implement must be resting on level and stable ground.

!

Do not stand near hydraulic hoses under pressure. Recover any spilled oil after servicing the

hydraulic system.

!

Prior to connecting the hydraulic hoses, make sure the male couplings on the implement and

the female connectors on the tractor are clean and free from dirt.

!

Before driving off, make sure that all screws and nuts are tight.

!

If the implement has been set to transport mode and is to be parked, it must always be parked

on a hard, flat surface. If this is not possible, the implement must instead be parked in working

mode.

!

Always use genuine Väderstad spare parts to maintain the quality and reliability of the imple-

ment. The warranty and any claim commitments will become void if third-party parts are used.