Summary of Contents for RAPID RD F Series

Page 1: ...Ver 1 3 07 06 01 900107 en Instructions Seed drill RAPID series RD 300 450 F No 10 026 11 999...

Page 2: ...2 Ver 1 3 07 06 01...

Page 6: ...6 Ver 1 3 07 06 01...

Page 16: ...Assembly instructions 16 Ver 07 06 01 07 06 01...

Page 23: ...RD 300 450 F Ver 1 3 07 06 01 23...

Page 41: ...RD 300 450 F Ver 1 3 07 06 01 41...

Page 47: ...RD 300 450 F Ver 1 3 07 06 01 47...

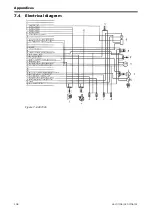

Page 108: ...Appendices 108 Ver 07 06 01 07 06 01 7 4 Electrical diagram Figure 7 8 307335...