Instructions and settings

66

Ver.2 01.11.2002

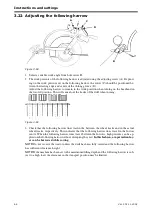

3.25 Adjusting the seed coulters

NOTE!

Before carrying out any work under the drill, make sure it is fully secure.

To ensure a satisfactory sowing result, it is important that the seed boxes are correctly installed on

the drill. Determine the installation height with regard to the conditions and the wear of the disc.

When the drill has been lowered with the discs resting on firm ground, the seed boxes should not

reach the surface (C > 0 mm). For sowing without ploughing in ground rich with straw litter as

well as for sowing in light soils, too low an installation may cause the discs to stop rotating. If

installed too high, seed placement may be impaired.

The seed coulters are spring-mounted on two bolts and the soft washers press the coulters closer

to the discs as the nuts are tightened. The nuts should not be tightened so much that the coulters

cannot be rocked by hand. It is important that the coulters do not press too hard against the discs

since this increases both wear and rotation friction.

In very loose soil and/or for very shallow sowing depth, the nuts may need to be loosened.

The drill should be hosed out before replacing seed coulters. When new coulters are fitted, the

width of the gap between coulters and discs must be checked. The gap must be wider at the top to

prevent blockage by straw or other trash. If the coulters are not making contact correctly, they be

adjusted by moving the metal plates at positions A and B inside or outside the mounting. The point

of contact can also be adjusted slightly by tightening the front nut more than the rear.

Figure 3.73

Figure 3.74

Table 3.7

Position

Reference gaps between discs and coulters

1

> 0 mm

2

0 mm

3

> 0 mm

A

C

B

1

2

3

Summary of Contents for RAPID RDA S Series

Page 1: ...Ver 2 01 11 2002 900225 en Instructions Seed drill RAPID series RDA 500 800 S No 12 000 12 799...

Page 2: ...2 Ver 2 01 11 2002...

Page 4: ...4...

Page 73: ...RDA 500 800 S Ver 2 01 11 2002 73...

Page 75: ...RDA 500 800 S Ver 2 01 11 2002 75 Figure 5 4...

Page 105: ...RDA 500 800 S Ver 2 01 11 2002 105...

Page 108: ...Appendices 108 Ver 2 01 11 2002 7 3 2 Hydraulic diagram RDA 800 S Figure 7 2 428718...

Page 121: ......