RDA 500-800 S

Ver.2 01.11.2002

65

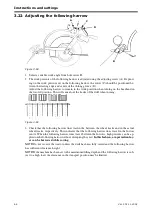

3.23 Adjusting Low lift height

Figure 3.70

Low lift height can be adjusted by moving the reed switch up or down in its holder using the wing

bolt (A) which is tightened using the wing nut (B).

NOTE!

This setting must be exact. The Low lift height must not be set either too high or too low.

Too high a setting reduces the pressure on the following harrow in the headlands (unless this is

required). Too low a setting means that tool bars and discs do not have sufficient ground clearance

when raised.

Too low a setting can also cause malfunction of Autostep in the Control Box.

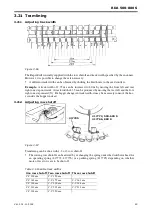

3.24 Locking the lifting rams during service

Never work beneath the drill during service or maintenance without first ensuring that it is safely

supported on stands and that all lifting rams are locked. There are 3 lifting rams to control sowing

depth of the drill and one push rod ram (extra in certain markets).The rams can be locked using

the relevant yellow locking devices. Raise the drill to the topmost position and push the stop onto

the master ram towards the cylinder end until the pin slips into place. When the drill is folded, the

two slave cylinders do not need to be locked, but check that the locking pins on both wing sections

are fully engaged.

Regarding placement of trestles, see ”

5 Maintenance and service” on page 74

Service work on the hydraulic system must always be done with the wing sections out and the drill

lowered to the ground.

Figure 3.71

Figure 3.72

Summary of Contents for RAPID RDA S Series

Page 1: ...Ver 2 01 11 2002 900225 en Instructions Seed drill RAPID series RDA 500 800 S No 12 000 12 799...

Page 2: ...2 Ver 2 01 11 2002...

Page 4: ...4...

Page 73: ...RDA 500 800 S Ver 2 01 11 2002 73...

Page 75: ...RDA 500 800 S Ver 2 01 11 2002 75 Figure 5 4...

Page 105: ...RDA 500 800 S Ver 2 01 11 2002 105...

Page 108: ...Appendices 108 Ver 2 01 11 2002 7 3 2 Hydraulic diagram RDA 800 S Figure 7 2 428718...

Page 121: ......