GB

GB

52

•

The flue gas ducting has to be made from tightened steel or stainless pipes. The horizontal part of the flue gas ducting must have a bias

of min. 5% (3°) upwards. Two 90° elbow-pieces can be used.

•

In case of placement of the flue gas ducting on the outer side of the building, it has to be equipped by thermal insulation.

•

Flue gas ducts with sharp bends and a horizontal routing decrease chimney draught. The maximum horizontal piece of the flue gas

ducting is 1 m, under condition that the length of the flue gas ducting is at least 5 m. The flue gas ducting has to be accessible for

checking and cleaning. It is necessary to provide possibility of sweeping of the entire length of the chimney, and the chimney door has to

be easily accessible.

•

Check attentively whether the chimney is tight and that no leakage of flue gases occurs around the chimney door and connection of the

flue gas ducts.

•

Flue gases are to be drawn through the flue gas ducting with the diameter of 150 mm connected to the neck of the flue gas ducting of the

stove, which is placed on the upper (rear) part of the stove.

4.5

Connection of central air supply

Connection of central air supply has to be realized in air-tight buildings, where the content of oxygen in the room

heated by the stove can be decreased.

•

Connect the hose to the suction neck for air on the rear wall (Ø 100 mm).

•

The entrance of the air supply line has to be placed in outdoor space or in sufficiently vented room of the building (a cellar, a technical

room, etc.).

•

At installation of the stove in a building with controlled ventilation of habitable premises, the entrance of air supply mustn’t be placed in a

room, which is connected to the associated ventilation system.

•

In order to ensure sufficient air supply, the supply line mustn’t by longer than 3 m and mustn’t have too much bends. The minimum

diameter of the supply line is 80 mm.

•

If the supply line enters into the outdoor space, it has to be bent by 90° in the down direction or has to be ended in the dead air region.

5

Commissioning

Wrong operation and insufficient combustion of fuel brings to a damage of the product.

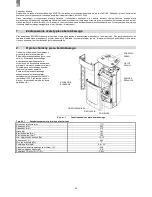

Operation of the ECHEDO stove is very simple. Control elements of the stove are displayed in fig. No. 5.

5.1

Stove door opening

Opening of the door in the horizontal direction is displayed in fig.

No. 5. Observe cleanness of sealing surfaces of the inner frame of the stove door so

that the closing was the easiest. Also keep the glass clean.

The stove door has to be always close during operation!

If necessary, always open the door slowly and carefully in order to avoid sudden

change of pressure in the heating chamber and escape of smoke into the room.

Fig.

№

. 5

Summary of Contents for ECHEDO

Page 12: ...CZ CZ 12...

Page 34: ...ES ES 34...

Page 46: ...FR FR 46...

Page 69: ...RU RU 69 2 3 3 1 3 2 100...

Page 72: ...RU RU 72 10 3 5 150 x 150 150 x 2 5 3 90 1 5 150 4 5 100 3 80 90 5 ECHEDO 5 5 1 5 5...

Page 73: ...RU RU 73 5 2 5 3 20 20 Tab 3 25 33 25 33 2 5 7 9 1 8 10 2 3 3...

Page 75: ...RU RU 75 6 1...

Page 76: ...RU RU 76 7 5 3 5 5 5 6 5 3 5 3 5 4 8...

Page 77: ...RU RU 77 9 2 5 6 750 C www viadrus cz...

Page 78: ...RU RU 78...

Page 89: ...SK SK 89...

Page 90: ...SK SK 90...

Page 91: ...SK SK 91...

Page 92: ...ECHEDO VIADRUS a s Bezru ova 300 E mail CZ 735 81 Bohum n info viadrus cz www viadrus cz...