VAG Operation and Maintenance Instructions • 14

For valves used in gas applications the use of suitable grease is

mandatory.

8 Trouble-shooting

For all repair and maintenance work, please observe the general

safety instructions described in Section 7.1!

9 How to contact us

Head office

VAG GmbH

Carl-Reuther-Str. 1

68305 Mannheim

Germany

Phone: +49 (621) 749-0

Fax: +49 (621) 749-2153

info@vag-group.com

http://www.vag-group.com

Service

Our service hotline can be reached 24/7 world-wide. In case of

emergency, please contact us by phone.

Service hotline: +49 621 - 749 2222

Service by E-Mail: service@vag-group.com

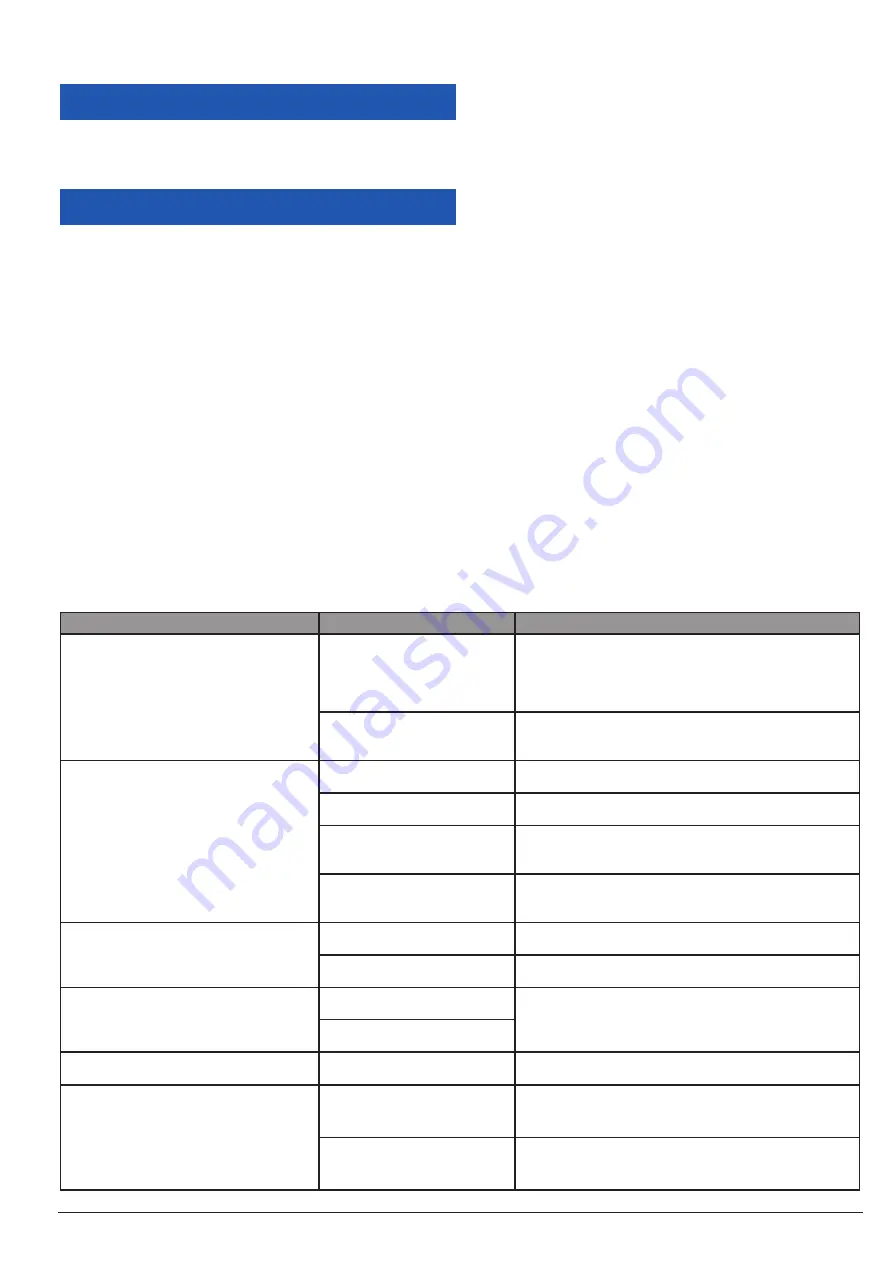

Problem

Cause

Remedial action

Valve makes noise

Unfavourable installation position

causing unfavourable flow around

or inside the valve (e.g. installed too

closely downstream of an elbow etc.)

Change installation position

Valve operating be-

yond its design limits

Check design and/or operation data, change flow resist-

ance in the valve, if required, by using different internals

Valve cannot be operated

Foreign matter jammed in the seat area Flush valve, dismantle, if necessary, and remove foreign matter

Gear blocked

Undo block

No electrical connec-

tion of electric actuator

Establish electrical connection

Unfavourable flow and im-

pairment of movement

Change installation position

Leaks in the body seat

Valve not completely closed yet

Close valve completely

Valve seal damaged or worn

Replace seal

Cavitation in valve

Valve operating beyond its design limits Butterfly valve not suitable for use as control valve. Replace valve by a

more suitable valve type.

Operational data changed

Leaks at the body

Deterioration of seals

Replace seals or collar

High operating forces

Seat of the valve polluted by deposits

Flush valve, dismantle, if necessary, and clean seat area

Valve is dry in pipeline, no medium

present

Valve can be operated more easily when wet