VAG Operation and Maintenance Instructions • 6

4.3 Installation position

The VAG DUOJET

®

Automatic Air Valve must always

be installed in an upright position. If installed in any

other position, the manu-facturer cannot ensure the

trouble free functioning of the valve or station (see Pic-

ture 10 - following page).

4.4 Installation note

Observe the following special installation notes in ac-

cordance with the specified hydraulic conditions and

installation positions.

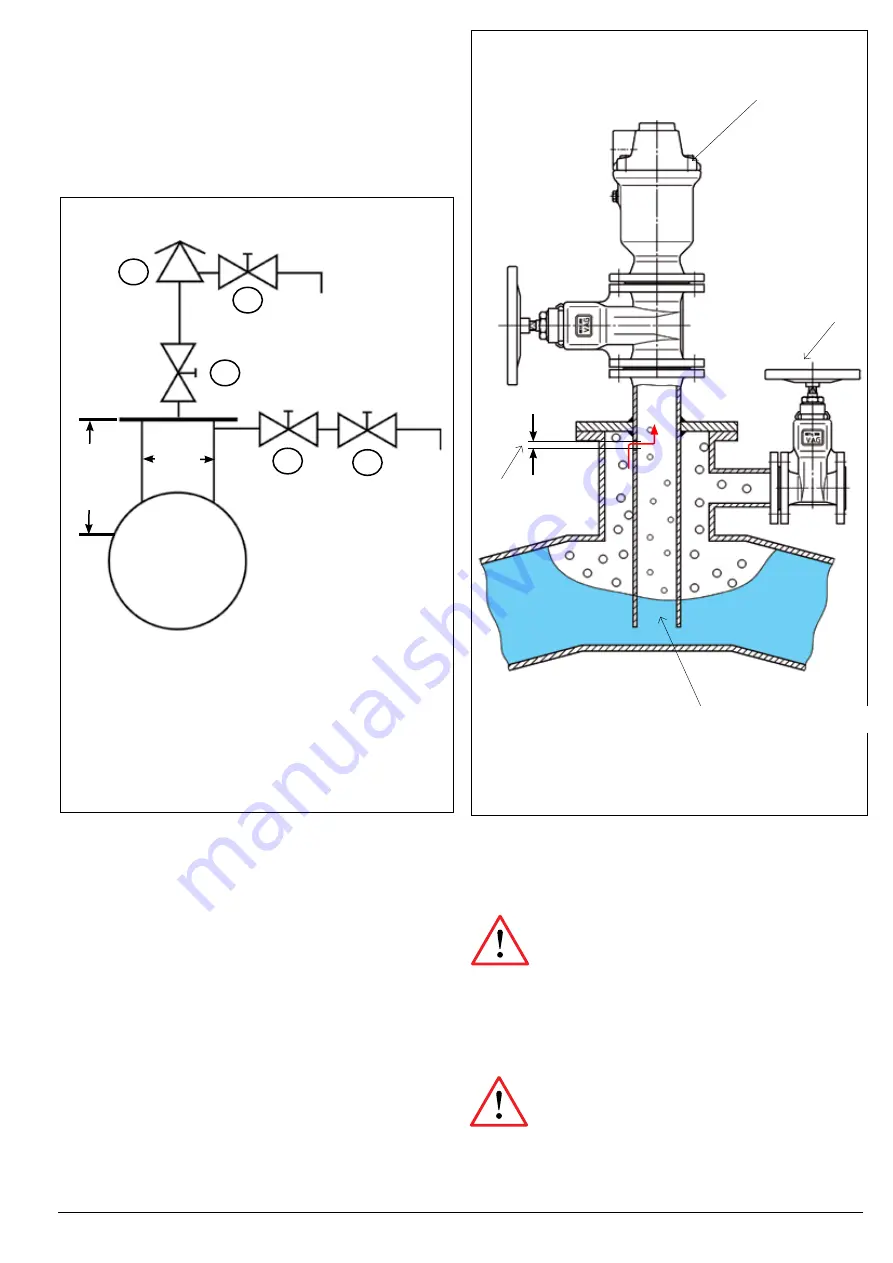

4.2.2 Installation for pipelines ≥ DN 600

For pipelines ≥ DN 600 the venting dome should not fall below

nominal size DN 600 and a height of h = 600 mm. In this case a

sufficiently dimensioned venting dome is provided.

To avoid a large installation height, manual venting can also be at-

tached laterally to the air dome. Here, however, a second central

stop valve upstream from manual venting is necessary.

≥

600 mm

~ DN 600

1

2

3

4

1

: Venting valve

2

: Manually operated air inflow and release, flush

valve

3

: Central stop valve

4:

Additional flush and discharge valve

4.2.3 Water flow rate

The water flow rate ascertained to fill a pipeline is equivalent to the

volume of air to be released. In this case venting should take place

at an overpressure of a maximum of 0.3 bar. In doing so, a change

in the density of the air can still be accommodated .

If when filling the rate in the pipeline exceeds 0.25 m/s, a dome

construction with an immersion pipe is recommended to reduce

pressure surges (Picture 9).

The water flow rate ascertained to empty a pipeline is equivalent

to the volume of air to be fed. In this case aeration should take

place at an underpressure of a maximum of 0.4 bar relative pres-

sure. In doing so, a change in the density of the air can still be

disregarded.

Picture 8: Pipeline

≥

DN 600

Picture 9: Dome construction with immersion pipe

3

VAG DUOJET

®

Automatic Air Valve

Manually operated

gate valve for air

inflow and release

Diameter:

DN

/

10

Immersion pipe