VAG Operation and Maintenance Instructions • 7

In case of submerged installation, increased actuation forces and

increased wear and tear (sometimes also accompanied by cor-

rosion) of the relatively moving parts are to be expected. This

must be taken into account when determining the maintenance

interals.

If the valve is installed as an end-of-line valve, it must be ensu-

red that its free outlet side is not accessible to interference from

any source.

Caution:

Installing the valve in the wrong location may cause

excessive dynamic torque and damage the valve.

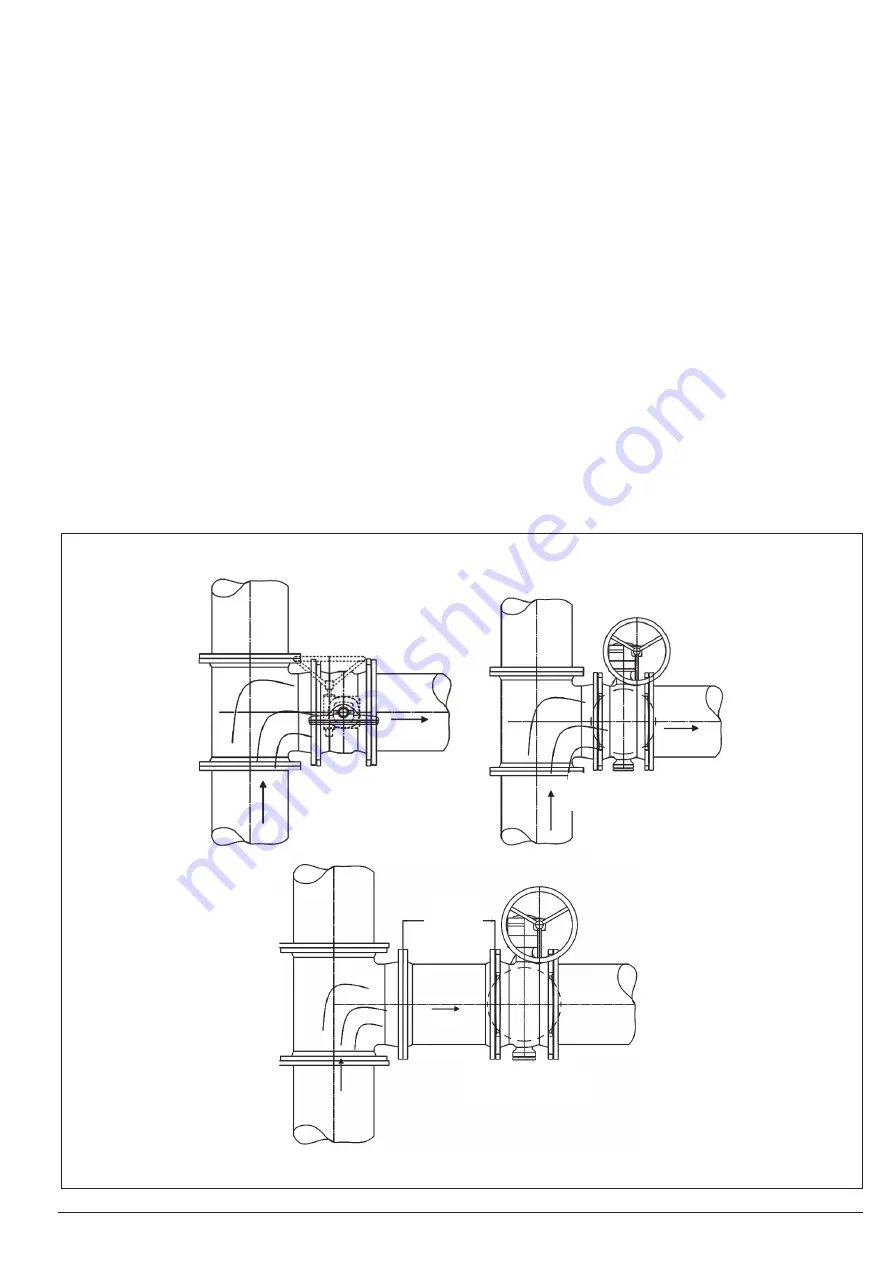

4.2.1 Installations in the pipeline upstream and

downstream of the valve /

Caution

• If the valve is used in contaminated media, a filter with a suita-

ble mesh size must be provided upstream of the valve in order

to prevent malfunction.

• Directly upstream of (3 x Valve size) ) and downstream of (3 x

Valve size) the VAG EKN

®

Butterfly Valve an inspection valve,

an elbow, T-pieces and Y-filters should be provided as other-

wise irregular flow may disturb the proper function of the VAG

EKN

®

Butterfly Valve.

• A damping zone between the branch/elbow and the valve is

ideal.

Picture 5: Installation of the VAG EKN

®

Butterfly Valve at elbows and branches

unfavourable

ideal

3 X

Valve

size

EKN

®

EKN

®

favourable

EKN

®