7.2 Inspection and operation intervals

The valve should be checked for tightness, proper operation and

corrosion protection “at least once per year” (DVGW Instruction

Sheet W

392

).

In case of extreme operating conditions inspection should be per-

formed more frequently.

7.3 Maintenance work and replacement of

parts

7.3.1 Design

The design view in Picture 12 serves as a partial overview for the

descriptions of the working steps below. For information about

spare parts and their part numbers, please refer to the document

VAG KAT 1310-E.

7.3.2 Recommendations for the replacement

of parts

Profile seals and O-rings must be replaced whenever necessary.

The replacement intervals depend on the operating conditions.

7.3.3 Cleaning and lubrication

When being replaced, the profile seal and the O-rings should al-

ways be lightly greased. Use lubricants with approval for applica-

tion with foodstuffs or drinking water.

Recommended lubricants:

For the profile seal and the O-rings: KLÜBERSYNTH VR 69-252

(with KTW approval for drinking water) Manufacturer: Klüber

Lubrication München AG, Germany.

7.3.4 Replacement of the profile seal

Due to the double-eccentric bearing, the profile seal can be re-

placed without disassembly of the disk. Valves of up to DN 1000

must either be completely dismantled from the pipeline or at least

disconnected from the pipeline on one side to replace the profile

seal. In the same way as for the installation of the disk, all safety

precautions need to be taken.

Disassembly of the sealing ring:

• Open the disk (2) until the profile seal (3) emerges from the body

• Unfasten the retaining ring screws (5.1)

• Remove retaining ring (1) and sealing ring (3)

• Clean the disk (2) in the sealing zone

• Check the seat ring in the body for damage or deposits

• Insert the new sealing ring into the groove of the disk and slight-

ly grease it with KLÜBERSYNTH VR 69-252

• Insert the hexagonal screws (5.1) and fasten them using the

torque specified in Table 1 (Section 7.3.6 Tightening torques

for screws)

7.3.5 Replacement of the O-rings in the

bearing

For this kind of maintenance work, the valve must be depressu-

rised.

• Turn the butterfly valve (2) into closed position

• Unfasten the hexagonal nuts at the gear flange and pull the gear

off the shaft (7)

• Loosen the threaded pin and pull off the coupling. Pull the ad-

justment spring (20) off the shaft

• In the depressurised pipeline, the hexagonal screws (14) are

unfastened and the bearing flange (10) as well as the bearing

cover (11) are pulled off. Slightly grease the O-rings (17 / 16) with

KLÜBERSYNTH VR 69-252 before installation.

• Reassembly is done in reverse order

• Tighten the hexagonal screws (14) only slightly to prevent ten-

sioning the bearing bush (12) on the disk (2). Secure the flange

position using the threaded pins (15).

• Assemble the adjustment spring (20) and the coupling

• Before mounting the gear, check whether the disk position and

the gear position match

• Fasten the gear fixing screws using the tightening torques spe-

cified in Table 3

• If necessary, readjust the limit stop of the gear. The limit stop

must only be adjusted when the valve is in closed position.

AUMA worm gear units are adjusted as specified in the AUMA

VAG Operation and Maintenance Instructions • 16

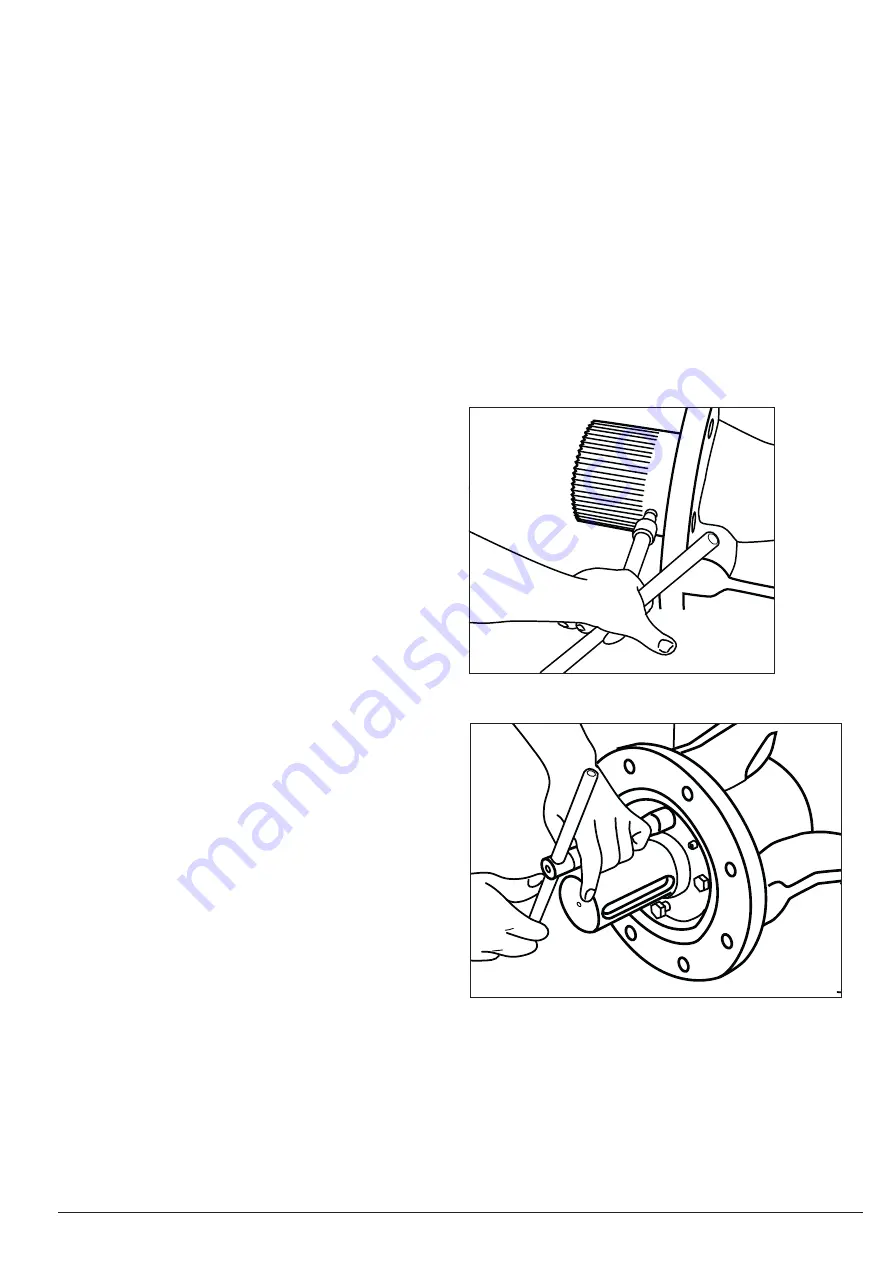

Picture 18: Replacement of O-ring - Step 1

Picture 19: Replacement of O-ring - Step 2