VAG Installation and Operating Instructions • 3

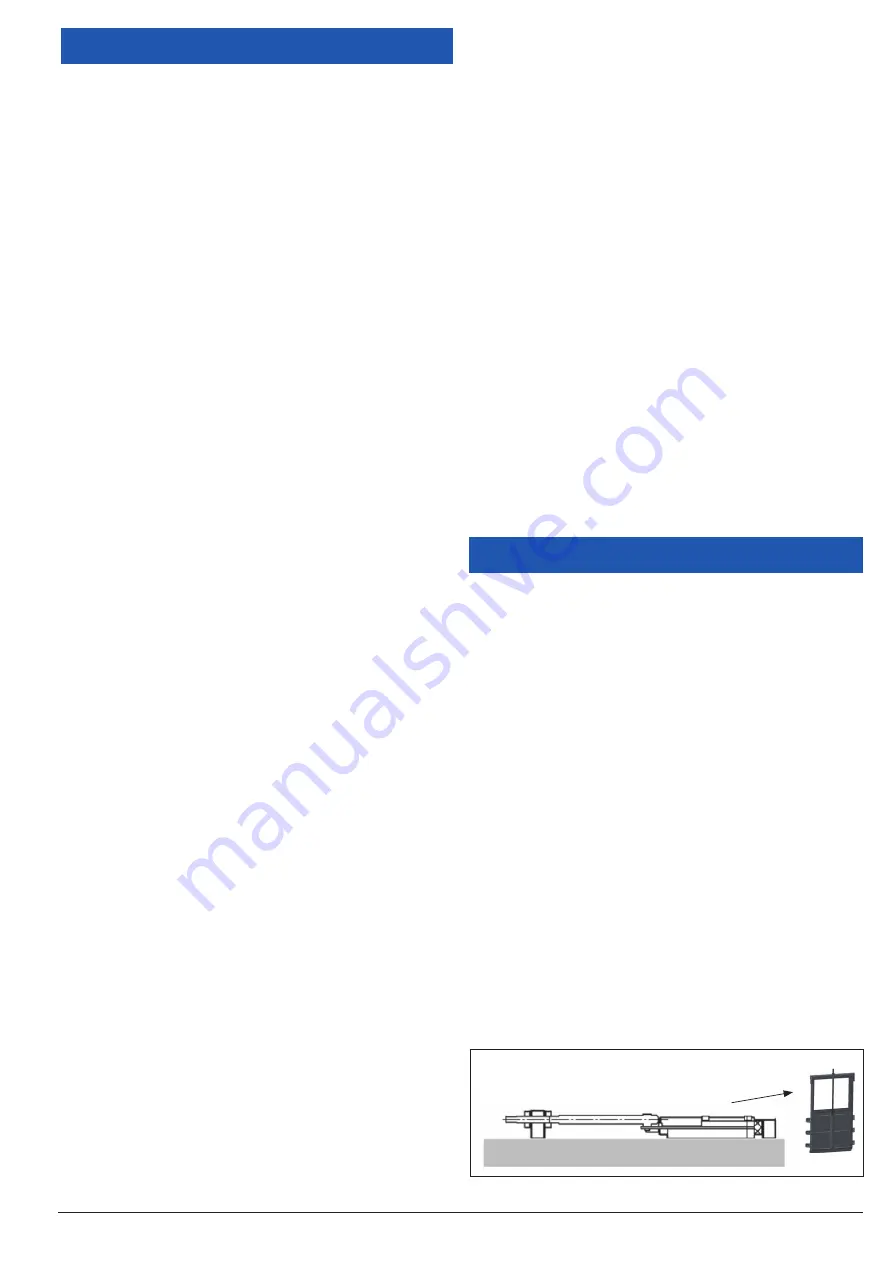

Bridge

Picture 1: Transport position of the EROX

®

plus

Penstock

1 General

1.1 Safety

These Installation and Operation Instructions must be observed

and applied at all times along with the general “VAG Installation

and Operation Instructions for Valves” (see www.vag-group.com/

Category: Installation and Operating Instructions).

Arbitrary alterations of this product and the parts supplied with it

are not allowed. VAG does not assume any warranty or liability for

consequential damage arising from non-compliance with these

instructions. When using this valve, the generally acknowledged

rules of technology have to be observed (e.g. DIN standards,

DVGW guidelines, VDI directives, etc.). The Penstock must only

be installed by qualified, specially trained staff. For further techni-

cal information such as dimensions, materials or applications,

please refer to the respective documentation (KAT-A 2452).

VAG valves are designed and manufactured to the state of the art

and their safety of operation is ensured in general. However,

valves may be potentially dangerous if they are operated impro-

perly or are not applied for the intended use.

Everyone dealing with the assembly, disassembly, operation,

maintenance and repair of the Penstock must have read and un-

derstood the complete Operating and Maintenance Instructions

(Accident Prevention Regulations, VBG 1 §14 ff [Regulations is-

sued by the Trade Associations].

The pressure in the pipeline section must be relieved and hazards

must be eliminated before protective devices are removed and/or

work is performed on penstocks. Unauthorised, unintentional and

unexpected actuation as well as any hazardous movements

caused by stored energy (pressurised air, water under pressure)

must be prevented.

For equipment for which monitoring is mandatory, the relevant

laws and regulations such as the Industrial Code, Accident Pre-

vention Regulations, Boiler Inspection Regulations, AD Data

Sheets (AD = Boiler Study Group) etc. must be complied with. In

addition to this, local accident prevention regulations must be

complied with.

For customised models of the VAG EROX

®

plus

Penstock, please

read the order-related instructions which may be included sepa-

rately and/or are included in the order documentation.

Arbitrary alterations of this product, the parts and accessories

supplied with it are not allowed. VAG does not assume any liabili-

ty for any hazards and damage resulting from the improper use of

the product and from non-compliance with the instructions con-

tained in this document.

1.2 Proper use

The VAG EROX

®

plus

Penstock is a shut-off and modulating

valve for use in wastewater systems.

Its standard version is suitable for sealing pipelines and openings

in constructions (depending on the nominal diameter) up to a

pressure of 10 m water column (1.0 bar) and for modulating the

flow rate. The pressure-rate is valid for both direction.

For the respective technical application ranges (e.g. operating

pressure, medium, temperature) please refer to the product-rela-

ted documentation (KAT-A 2452).

Any deviating operating conditions and applications require the

manufacturer‘s prior written consent!

These Installation and Operation Instructions contain important

information on the safe and reliable operation of the VAG

®

plus

Penstock.

Compliance with these Installation and Operation Instructions

helps:

• to prevent hazards,

• to reduce repair costs and down-times of the Penstock and/or

the entire equipment,

• to improve the operational safety and useful life of the equip-

ment.

1.3 Identification

According to DIN EN 19 all valves bear an identification label spe-

cifying the nominal diameter (DN), nominal pressure (PN), body

material and the manufacturer’s logo.

A rating plate is attached to the body and contains at least the fol-

lowing information:

VAG

Manufacturer’s name

DN

Nominal diameter of the valve

PN

Nominal pressure of the valve

Serial number of the valve and Date of manufacture

2 Transport and storage

2.1 Transport

For transportation to its installation site, the Penstock must be pa-

cked in stable packaging material suitable for the size of the Pen-

stock. The container also needs to ensure that the Penstock is

protected against weather influences and damage. When the

Penstock is transported over long distances (e.g. overseas) and

exposed to special climatic conditions, it needs to be protected

by sealing it in plastic wrapping and adding a desiccant.

Any assemblies must be protected against damage by external

influences during transport and storage.

The VAG EROX

®

plus

Penstock must be transported lying flat on

its rear side and in almost closed position (cf. Picture 1). Special

varieties and Penstocks in nominal sizes which due to their overall

size cannot be transported in a lying position will be delivered in a

special transport rack.

When actuators are mounted to the bridge of the Penstock, safe

bearings for the actuators need to be provided to prevent the

joints from being exposed to shunt loads.

For transport purposes and also to support assembly, lifting de-

vices such as cables and belts must always only be attached to

the bridge of Penstock (see Picture 1). The actuator, which may

have been assembled, is not suitable for this purpose. The length