VAG Installation and Operating Instructions • 5

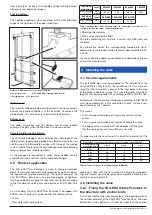

Penstock

dimensions (mm)

400x400

500x500

600x600

700x700

max. leakage

(1%)

liter/

minute

0,048

0,06

0,072

0,096

Penstock

dimensions (mm)

900x900 1000x1000 1200x1200

max. leakage

(1%)

liter/

minute

0,108

0,12

0,144

Table 1: Leakage rates

Note: The table refers to "on seating" pressure. For "off

seating" pressure the values can be multiplied by 3.

tures which form the basis of its reliable and tight sealing function

and ensure low operating torques.

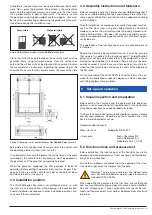

Locking system:

This additional locking system (used from DN 700 on) effectively

supports the tightness of the upper lateral seal.

Profiled seal:

The specially shaped profiled seal inserted in the frame section

ensures the excellent tightness of the Penstock. To replace the

profiled seal, it is not necessary to dismantle the Penstock.

Bottom seal:

The wide, voluminous and flat bottom seal ensures reliable

sealing of the gate when the Penstock is in closed position.

Patented sliding wedge system:

The VAG sliding wedge system combines the advantages of the

sliding system (good guiding properties, vibration-free, valve can

also be used in intermediate position) with those of the wedge

system (relief of the load on the seal, reduced wear, low operating

forces and excellent, reliable tightness).

As the wedges are connected in series, more wedges can be

used and the frame sections remain compact and rigid.

3.2 Fields of application

The VAG EROX

®

plus

Penstock is used in sewage treatment

plants, in raw water and waste water pipelines as well as in indus-

trial applications and flood protection. The special feature of the

VAG EROX

®

plus

Penstock is its very high degree of tightness

which considerably exceeds the leak rates admissible according

to the standard for sluice gates and penstocks (DIN 19569, Part

4).

As a standard, the VAG EROX

®

plus

Penstock is equipped with

EPDM seals. Therefore it can be used for the following fluids:

• Water

• Raw water and cooling water

a: Locking system

b: Patented VAG sliding wedge system

d: Bottom seal

Picture 5: EROX

®

plus

special technical features

c: Profildichtung

a

b

d

c

• Municipal waste water

• Weak acids and alkaline fluids

For fluids containing fats and oils, a variety with NBR seals are

available.

For information about the corresponding temperature limits,

please refer to the product-related technical documentation (KAT-

A 2452).

In case of deviating operating conditions and applications, please

consult the manufacturer.

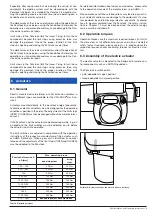

4 Installing the valve

4.1 On-site requirements

The installation area must be prepared for the installation of the

VAG EROX

®

plus

Penstock. On the installation site it must be en-

sured that the constrution is even and free from pores in the area

of the entire supporting surface. The concrete quality must be at

least that of strength grade C 25 according to DIN 1045/DIN 1084.

Furthermore, the dimensional tolerances according to DIN 18202

must be complied with. In this connection, Table 2, surface even-

ness tolerances line 7 applies.

This means:

• 3 mm maximum deviation per 1 metre of concrete surface

and/or

• 5 mm maximum deviation per 2 metres of concrete surface

• The edges of the structure must not be broken off to ensure

that the sealing ring rests completely on concrete.

If a pipe runs into the construction it is essential to ensure that the

pipe end is flush with the construction. Existing old valve parts

(e.g. old frames) need to be removed completely before the as-

sembly of a new penstock.

4.2 Installing the valve

4.2.1 Fixing the VAG EROX

®

plus

Penstock to

the structure with anchor bolts

First check whether the clear dimension of the opening matches

the nominal diameter of the VAG EROX

®

plus

Penstock. The clear

dimension of the opening must never be larger than the nominal

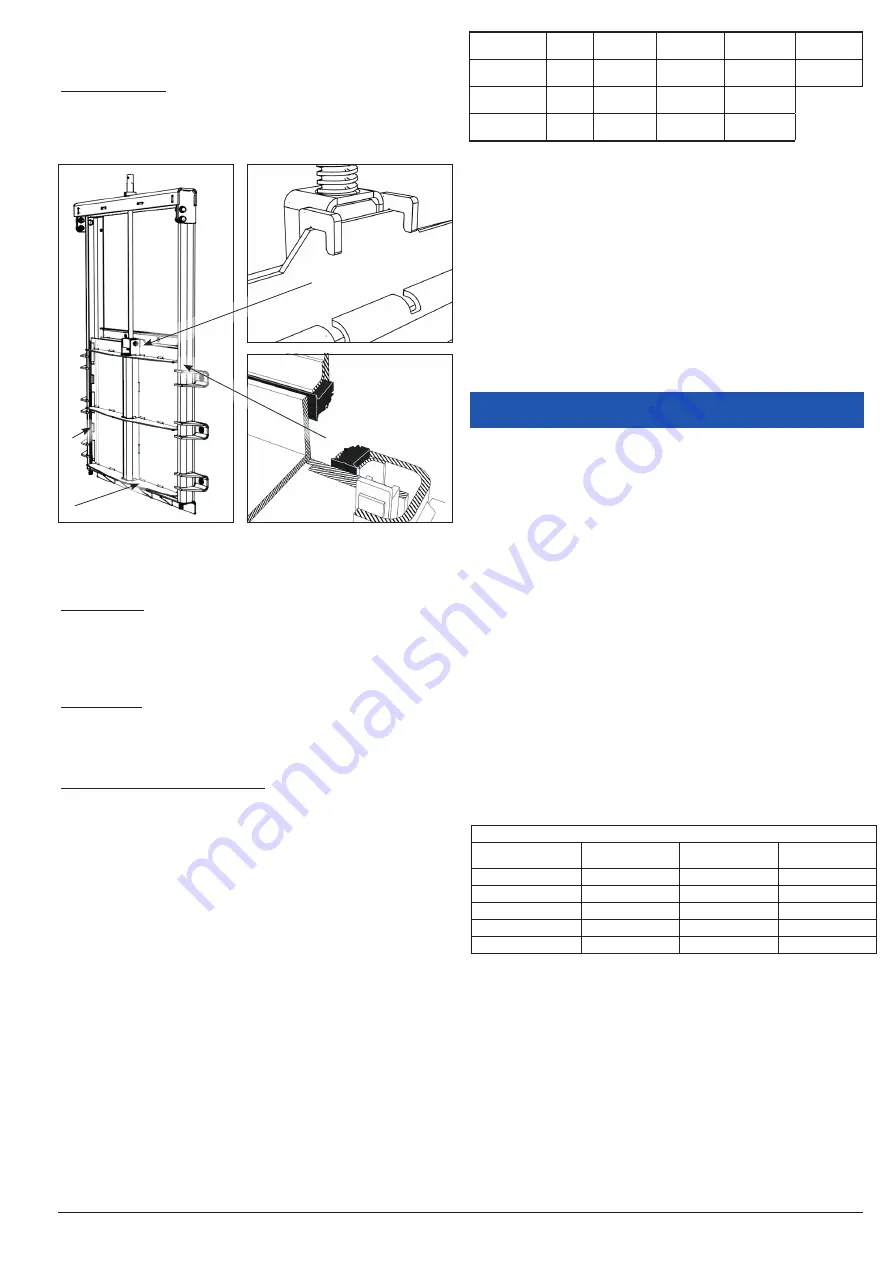

Limit values of evenness tolerances in mm according to

DIN EN18202

Distance between

measuring points

Line 5

Line 6

Line 7

0,1 m

5

3

2

1 m

10

5

3

4 m

15

10

8

10 m

25

20

15

15 m

30

25

20

Table 2: Table tolerances in Civil Engineering (DIN18202)