VAG Installation and Operating Instructions • 6

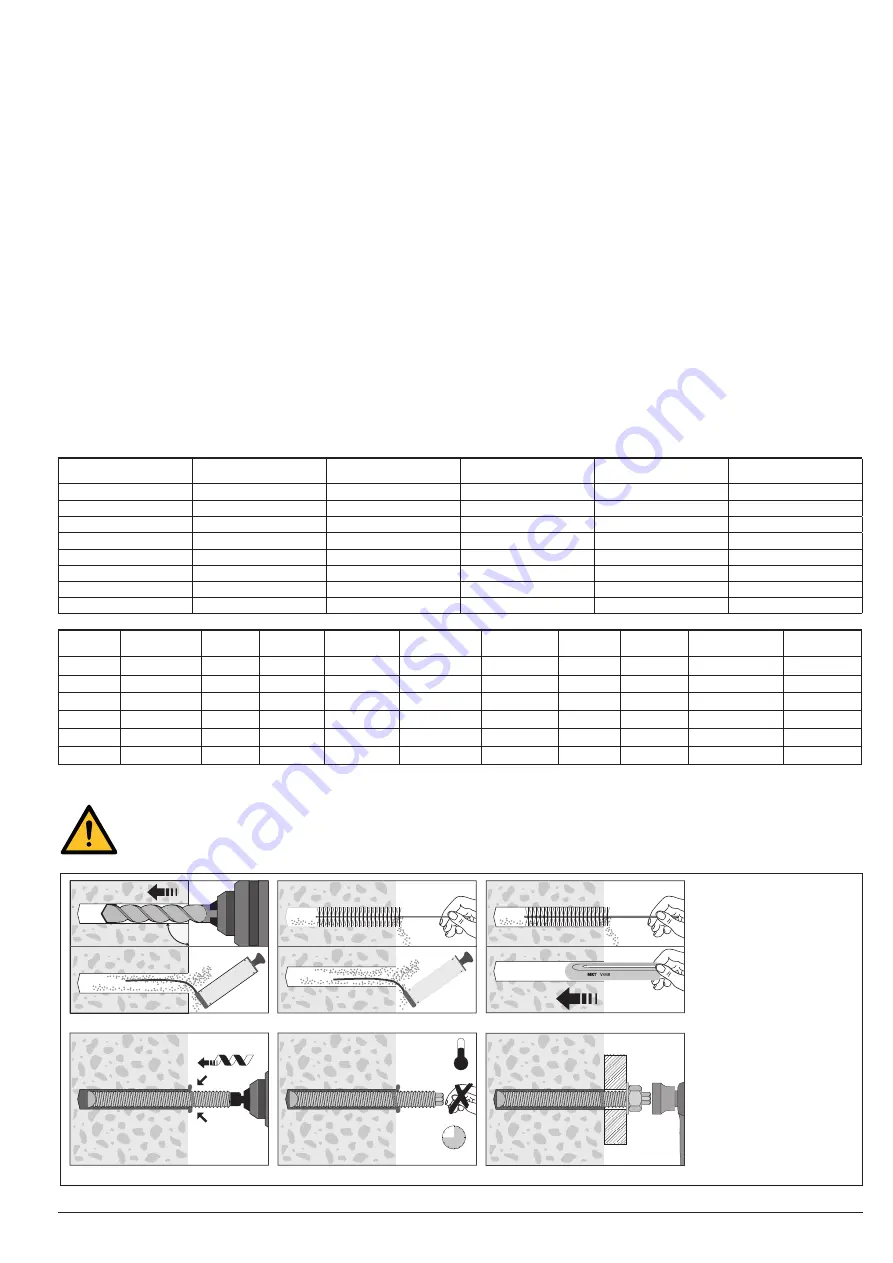

Table 3: Drill hole and anchor bolt size

1. Drill the drill hole

2. Clean the bore hole with a

brush and blow out the dust

3. Insert the cartridge

4. Insert anchor rod with

rotary movement

Excess adhesive swells

from the bore hole

5. Attention! Remo-

ve swollen adhesive!

5. Observe the curing time!

6. Install the penstock. Ob-

serve the tightening torque!

Before exposing the Penstock

to any loads, the setting time

of the adhesive must have

expired.

If the Penstock is anchored to

a humid surface, the setting

times must be doubled!

Picture 6: Proper handling of chemical anchors

Montage

N

m

T

inst

+20 ∞C

20 min.

90∞

1.

2.

3.

4.

5.

6.

Nominal

diameter

Drill hole

diameter

Number of drill

holes

Deep of drill

holes

Anchor bold size

max. tightening

torque

400x400

Ø 14,5 mm

4

110 mm

M12x160/97 mm

40 Nm

500x500

Ø 14,5 mm

8

110 mm

M12x160/97 mm

40 Nm

600x600

Ø 14,5 mm

8

110 mm

M12x160/97 mm

40 Nm

700x700

Ø 17 mm

10

125 mm

M16x190/95mm

60 Nm

800x800

Ø 17 mm

10

125 mm

M16x190/95mm

60 Nm

900x900

Ø 17 mm

12

125 mm

M16x190/95mm

60 Nm

1000x1000

Ø 17 mm

12

125 mm

M16x190/95mm

60 Nm

1200x1200

Ø 17 mm

14

125 mm

M16x190/95mm

60 Nm

size

borehole

diameter

borehole

number

borehole

depth

anchor size

max. torque

moment

borehole

diameter

borehole

number

borehole

depth

anchor size

max. torque

moment

1300x1300

Ø 18 mm

10

175 mm

M16x220/160

60 Nm

18 mm

5

125 mm

M16x190/95mm

60 Nm

1400x1400

Ø 18 mm

10

175 mm

M16x220/160

60 Nm

18 mm

5

125 mm

M16x190/95mm

60 Nm

1500x1500

Ø 18 mm

10

175 mm

M16x220/160

60 Nm

18 mm

7

125 mm

M16x190/95mm

60 Nm

1600x1600

Ø 18 mm

12

175 mm

M16x220/160

60 Nm

18 mm

7

125 mm

M16x190/95mm

60 Nm

1700x1700

Ø 18 mm

12

175 mm

M16x220/160

60 Nm

18 mm

7

125 mm

M16x190/95mm

60 Nm

1800x1800

Ø 18 mm

14

175 mm

M16x220/160

60 Nm

18 mm

9

125 mm

M16x190/95mm

60 Nm

The VAG EROX

®

plus

Penstock is now tightened evenly and crosswise on the building wall until the holders just rest against

the building wall. Thus, the wall seal of the slider is optimally biased to the building wall. It is essential to wait for the prescri-

bed hardening time of the chemical compound anchors before full load of the VAG EROX

®

plus

Penstock.

width of the VAG EROX

®

plus

Penstock. The profiled seal which

seals the penstock against the wall must rest completely on the

even wall surface.

At the beginning of its assembly the VAG EROX

®

plus

Penstock is

opened completely. Place the penstock gate in front of the ope-

ning in the structure so that the opening is completely centred in

the clear opening of the penstock. In this installation position, the

construction of the penstock ensures that the minimum distance

to the wall is observed when you drill the anchoring holes for the

chemical anchors.

The VAG EROX

®

plus

Penstock is now aligned with a level and

then fixed with e.g. with stays. The profiled seal which seals the

penstock against the wall must rest completely on the even wall

surface of the structure.

The VAG EROX

®

plus

Penstock may now be used as a drilling

template. With a suitable drill (for the size of the drill hole see Pic-

ture 4) the holes for the anchor bolts are drilled through the holes

of the attachment claws. Afterwards the holes must be blown

out. Any loose drilling dust remaining in the holes will affect the

bonding strength of the chemical reaction holes.

Any incorrect drilled holes must be properly closed before the

Penstock is attached. This prevents the steel reinforcement of the

concrete exposed by drilling from carrying corrosion into the

structure.

Anchor bolts (chemical reaction anchors) must be installed accor-

ding to the instruction of the suppliers of the chemical reaction

anchors. Please only use the attachment material included in the

scope of supply (see Figure 7) observe the instructions provided

on the proper handling of chemical anchors (Picture 8).

After the setting time unfasten the VAG EROX

®

plus

Penstock to

remove any excess synthetic mortar which may have emerged

from the holes with a screw driver or chisel. Any excess adhesive

that remains outside the holes prevents the correct seating of the

penstock wall seal on the structure and thus affects the sealing

effect.

Now the VAG EROX

®

plus

Penstock is fastened evenly to the sur-

face of the structure and the bolts are fastened cross-wise to the

wall of the structure until the retainers rest evenly on the surface

of the wall. This ensures that the wall seal of the penstock is opti-

mally pre-tensioned on the wall surface. Before full load is applied

to the VAG EROX

®

plus

Penstock, the prescribed setting time of

the chemical reaction anchor bolts must have expired.