VAG Installation and Operating Instructions • 7

The now operational VAG EROX

®

plus

Penstock must be cleaned

from drilling dust and drilling residues, in particular the inner area

between the frame and the gate as well as the thrust wedges.

4.2.2 Assembly of the VAG EROX

®

plus

Penstock; Control distance measure of slide

plate

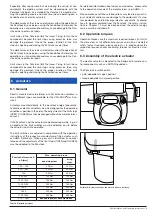

When mounting the anchor rods for the upper mounting holes

(see picture 9), attention must be paid to compliance with the dis-

tance dimension C (see table above) due to the risk of collision

between the slide plate and the anchor rod.

Tighten the nuts on the upper anchor rods so that the distance C

between the slide plate and the cross member is largely the same

over the entire width. By slightly opening the slide plate, check if

it opens without collision.

4.2.3 Assembly of the VAG EROX

®

plus

Penstock on a pipe flange (EROX

®

plus

version

with flange adapter)

The version VAG EROX

®

plus

has a flange adapter and is inten-

ded for attachment to a pipe flange EN 1092-2 PN 10. In sizes DN

150 up to and including DN 600, the VAG EROX

®

plus

is connec-

ted to the pipe flange via a flange adapter.

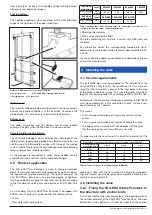

On the tube side, the flange adapter is provided with threaded

bolts. They are used to mount the adapter plate to the pipe flan-

ge. The threaded bolts are acc. to DIN EN 1092-2, PN 10. A seal

provided with the seal between the pipe flange and the flange ad-

apter (Picture 7).

Attention! When mounting to a pipe flange with collar,

the flange thickness must be compensated by interpo-

sing washers between flange and adapter plate. Thus,

an undue bending of the adapter flange is prevented

when tightening the fastening nuts.

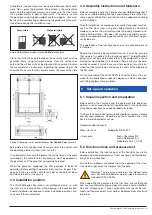

The flange adapter is also provided with threaded bolts on the sli-

de side. Here, the slider is mounted on the holders. After assem-

bly, the flange adapter on the slide side serves as a bearing sur-

face for the wall seal of the VAG EROX

®

plus

slide valve (Picture 8).

Slide the spindle slide with the holder holes over the threaded

bolts and screw them firmly onto the adapter plate using the sup-

plied fastening parts. The fastening nuts are alternately tightened

crosswise until all holders are in metallic contact with the flange

adapter.

For assembly, the nuts and washers supplied must be used.

Attention! Since the threaded bolts are not symmetri-

cal, it is important to pay attention to the correct ori-

entation when mounting the adapter plate. The slide-

side threaded bolt must be arranged laterally and

vertically.

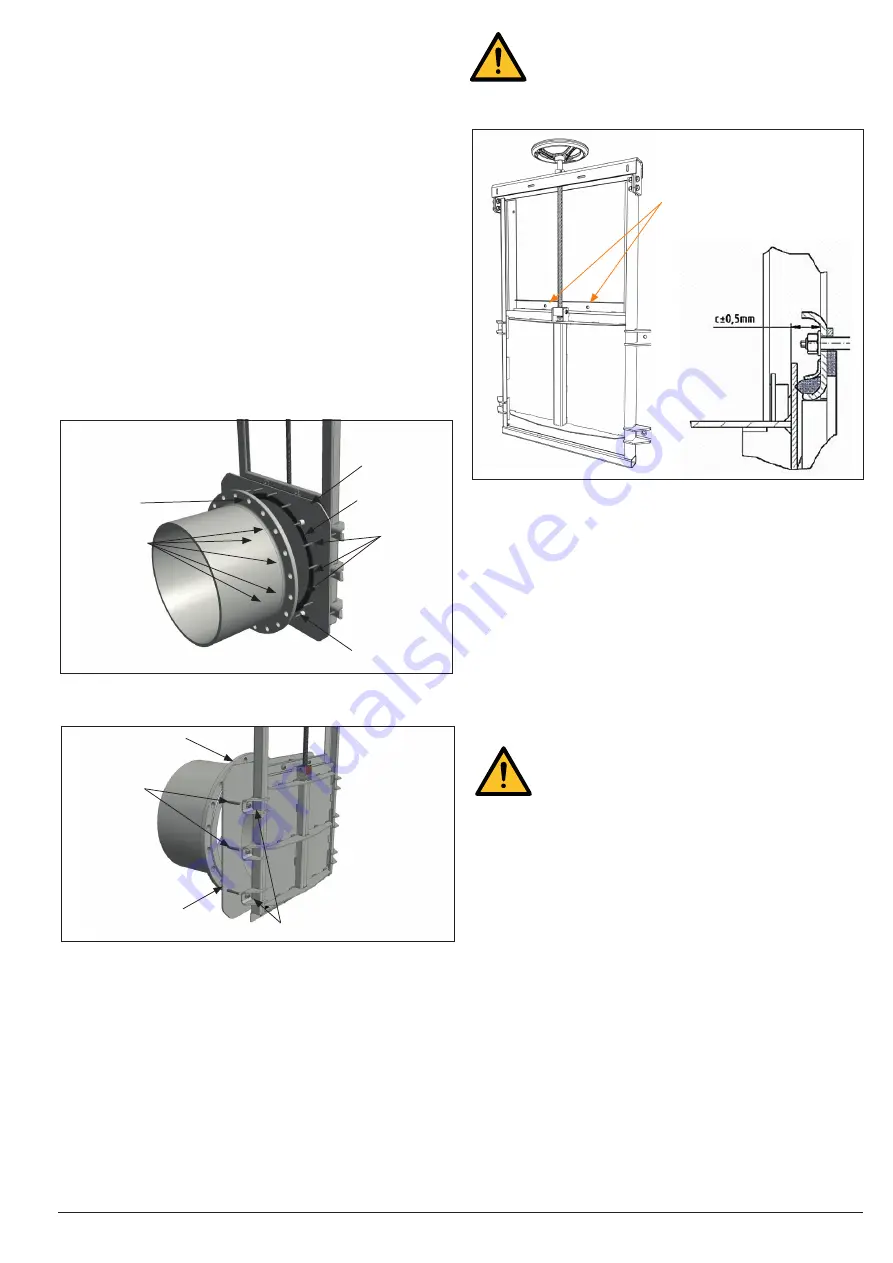

4.2.4 Channel mounting

On the sides and in the invert of the channel, box outs must be

prepared to receive the frame (see picture 11). When securing the

penstock in the box outs for grouting, make sure that it is free

from tension.

Before installing the penstock, check whether its dimensions

match the inner dimensions of the channel. The inner dimensions

of the channel must not exceed the outer dimensions of the pen-

stock frame.

Install the penstock with its slide gate closed. First install the ad-

justment screws supplied in the threaded anchor plates located

on the sides of the penstock frame. Then lower the closed pen-

stock into the box out of the channel.

Using a spirit level, first align the penstock sill so that the bottom

seal is flush with the channel invert. It may be necessary to secu-

re the penstock using wooden wedges. Aligning the penstock sill

flush with the invert prevents the build-up of sediments in the seal

area.

Picture 9: Montage Ankerstangen für obere Befestigungsbohrung

Upper mounting holes

Pipe flange

Threaded

bolts

Flange adapter

Retainer

Picture 8: Assembly of the penstock on the adapter plate

Pipe flange

Nuts and

washers

Picture 7: Mounting of the adapter plate to the pipeline flange

Seal

Spacers

Threaded

bolts

Flange adapter