VAG Installation and Operating Instructions • 8

Furthermore, the penstock must be centred between the channel

walls. Now secure the penstock into position in the vertical box

outs using the adjustment screws and make sure that the frame

sill is perpendicular to both channel walls. If necessary, secure

the penstock using wooden wedges or other supports. Care must

be taken to avoid twisting or deforming the guide rails of the pen-

stock frame during this installation step.

Close the vertical box outs between the concrete walls and the

penstock frame using formwork boards. Now the vertical box

outs and the sill box out can be grouted with concrete. Observe

the manufacturer’s instructions regarding the processing of the

concrete. Make sure that no concrete enters the areas of the slide

gate guide rails in the penstock frame or comes into contact with

the operating elements (stem, stem nut, etc.).

It is absolutely necessary to observe the curing times of the grout

specified by the manufacturer. No pressure must be applied on

the penstock until the grout has completely hardened.

When the grout has hardened, the VAG penstock is ready for

operation. Before putting the penstock into service, inspect it es-

pecially in the area of the seals for any dirt or concrete residues

and clean the parts, if necessary.

4.3 Installation position

The VAG EROX

®

plus

Penstock is assembled vertically, i.e. with

the stem in a vertical position, at the opening in the construction.

Should installation be required in other installation positions, ple-

ase consult the manufacturer.

Permissible

Not permissible

Picture 10: Installation position of the VAG EROX

®

plus

Penstock

4.4 Assembly instructions and fasteners

Before assembly, check the Penstock for possible damage that it

may have suffered during transport and storage. Protect the Pen-

stock against dirt on the construction site by adequate covering

until installation.

Prior to installation, all components essential for proper function,

such as the stem, stem nut, gate, sliding elements and sliding

wedges as well as the wall seal must be thoroughly cleaned to re-

move all dirt particles. VAG does not assume any liability or war-

ranty for consequential damage caused by dirt, shot-blasting gra-

vel residue etc.

The operability of the functional parts must be checked prior to

installation.

Should the Penstock be repainted later on, it must be ensured

that no paint is applied to the functional parts. The identification

plates must not be painted over either. If the equipment is sand-

blasted for cleaning prior to installation, these parts must be ade-

quately covered. If solvents are used for cleaning, it must be en-

sured that the solvents do not destroy the seals of the pipeline or

the Penstock.

For the assembly of the VAG EROX

®

plus

Penstock it must be en-

sured that suitable load suspension devices as well as transport

and lifting equipment are available.

5 Set-up and operation

5.1 Visual inspection and preparation

Before putting the Penstock and the equipment into operation,

perform a visual inspection of all functional parts. Check whether

all bolted connections have been properly fastened.

The Penstock have been factory-lubricated for assembly, storage

and transport purposes. Depending on their condition, they may

have to be relubricated at set-up.

Recommended lubricants:

Stem, stem nut:

Klüberplex BE 31-502

• Seal, gate:

Fuchs Chemplex Si 2

Fuchs Notropeen Si 1

Klüberbeta

VR

67-17002

5.2 Function check and pressure test

Before installation, the function parts of the Penstock have to be

opened and closed completely at least one time and their opera-

bility has to be checked.

Ensure that no objects are present near the opening of the struc-

ture which might block the movement of the gate.

Warning! The pressure exerted on the closed valve

must not exceed it belastet werden (siehe technisches

Datenblatt KAT-A 2452).

When operating the penstock for the first time, ensure that gate

and any mounted actuating components move evenly, vibration-

free and without noise. These components must never be jam-

med and their movement must neither be blocked nor otherwise

impaired.

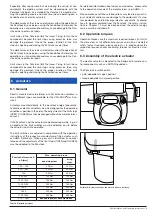

100

100

200

200

Picture 11: Example of a channel installation of the VAG EROX

®

plus

Penstock